Challenges and benefits of microelectronic design in circuit board design

The microelectronic market is growing rapidly. We will focus on the advantages and challenges of microelectronic design. In order to make full use of the field of microelectronics, circuit board companies must ensure that they adapt to the limitations and advantages of microelectronics.

What is the importance of microelectronics?

In order to fully understand the advantages and challenges of microelectronics technology, we must first solve some factors that drive the company to develop in this direction.

It can be said that the biggest problem here is consumer demand. In some ways, this is obvious - consider the development of cellular phones over the past two decades, from brick boxes to ultra-thin devices as we know them today. The same trend can be seen in laptops, tablets, etc. In these circumstances, electronics companies are responding to consumer demand for smaller products.

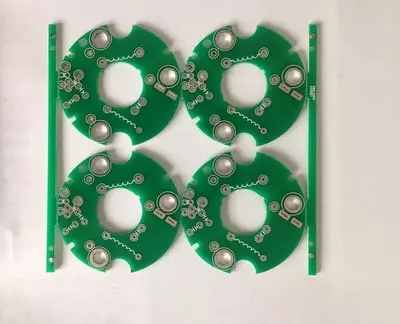

It must also be recognized that the rapid popularization of wearable devices and the Internet of Things is driving the development of microelectronic devices and components. In these cases, it is not just consumer preference that leads to smaller designs. Instead, these solutions can only exist with the development and use of microelectronics technology, which is a simple fact. The company is contacting design or manufacturing plants to discover the possibility of microelectronics and make corresponding efforts immediately.

The IoT market will be worth hundreds of billions of dollars in a few years. In the field of health care alone, the market for medical devices and wearables relying on microelectronics technology itself will be worth billions of dollars in essence.

Challenges of Microelectronics

So, what is the challenge of microelectronics to PCB designers?

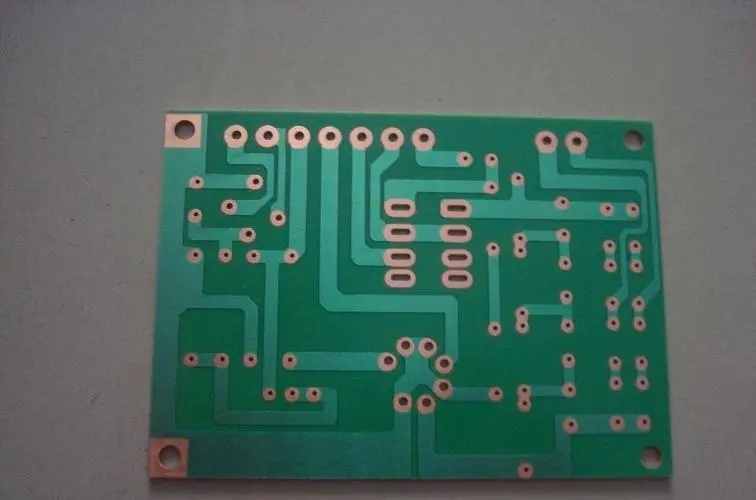

As the size shrinks, the circuit board becomes denser. Designers need to package more I/Os into a smaller space and keep these pad arrays as close together as possible. The problem here is that as the spacing becomes tighter, the routing and spacing become tighter, which brings challenges to signal reliability. In a typical circuit board, unlike a micro printed circuit board, the signal on the trace will lose energy as the trace becomes smaller. This is due to the simple fact that it is extremely difficult to ensure the uniform routing of signals when relying on the subtractive circuit board printing method at the micro level.

This may bring serious problems to the microelectronic equipment itself. Perhaps most notably, weak signal strength will lead to reduced battery life. For electronic equipment, this is an increasingly important issue, involving a wide range of spaces, including all the highlighted spaces mentioned above. For consumer electronics, the demand for mobile phones and other handheld devices is obvious. They can be used for a long time without charging. For other microelectronic problems, such as IoT sensors and implants, charging may not be feasible or possible because the device itself cannot reach. In these cases, impressive battery life is an absolute prerequisite for successful design.

Any micro design that cannot completely solve the microelectronic challenges brought by increasing the density of circuit boards will face the risk of not fully exerting its full potential, or may not work properly.

The good news is that none of these challenges in microelectronics is insurmountable.

How to Push Microelectronics Technology Forward with Micro PCB

If you need to make a single prediction on the development of the electronic market in the coming decades, then perhaps the safest choice you can make is that the industry is moving towards the microelectronics field. After all, this has been the case in the past 20 years, and there is no reason to think that it will be different in the near future. If so, this trend may accelerate.

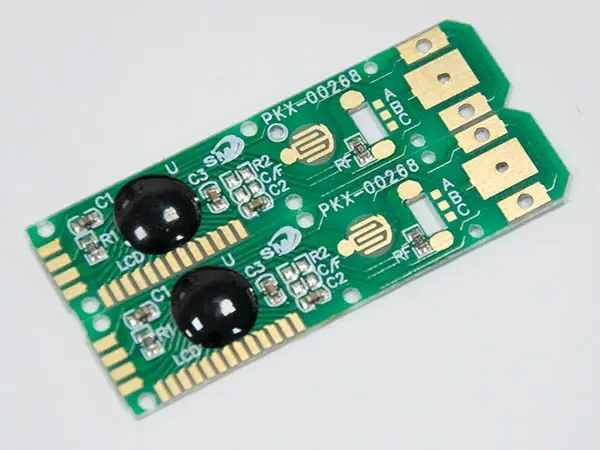

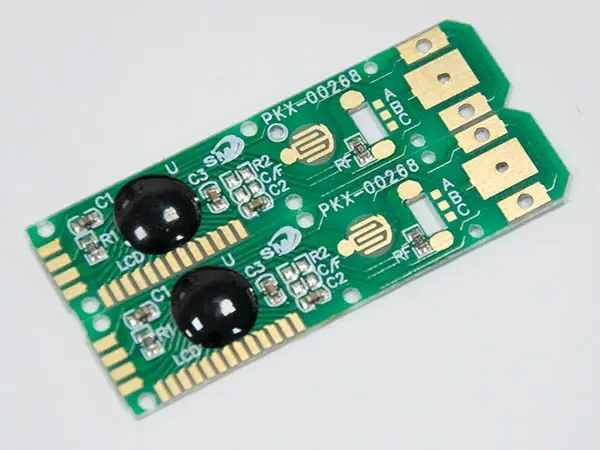

Recently, we introduced the current state of microelectronics technology, including some of its most noteworthy applications. We also introduce some of the most noteworthy benefits and challenges of microelectronic design. Today, we will carefully study a more specific part of this field: micro printed circuit boards. Micro PCB plays a key role in improving the efficiency and efficiency of microelectronic design, and opens up the possibility that could not be realized before.

Overcoming the Challenge of Micro PCB to Create Better Microelectronics Products

We discussed how the shrinking size of electronic products caused serious design difficulties. Most notably, tighter wiring/space on the circuit board can lead to signal loss, resulting in a variety of problems. This includes shortening battery life and reducing energy efficiency, both of which may seriously undermine the value of new microelectronic designs.

The ideal solution to this problem is to use smaller PCBs that can adapt to these reduced sizes without causing subsequent quality degradation. Naturally, this is easier said than done. In general, the development of PCB design industry towards miniaturization is driven by the needs of equipment designers and manufacturers. However, there are (or at least already exist) limitations on the trace and space and the minimum size of the board itself.

However, recent advances in micro PCB technology make it possible to adapt to this transformation. Key development: addition process.

Additive and subtractive micro PCB

Until recently, the minimum width of PCB routing and space was 3 mils. The problem is not that PCB manufacturers cannot produce lines lower than this figure, but that they cannot reduce the size without sacrificing consistency and accuracy. This is an inherent problem in the subtraction method of microcircuit printing technology. Traditional methods are not accurate in such a small size, so there is always a certain degree of uncertainty in line width. As electronic equipment and circuits become smaller and smaller, the lack of accuracy becomes more intractable and unacceptable.

However, this is no longer the case for additive based PCB processes. The additional method is not to remove copper (that is, subtract), but to add copper to the PCB. This technology is more accurate, allowing manufacturers to provide smaller tracking space and higher density per inch without encountering the signal loss problem highlighted above. This is largely due to the fact that the addition process can provide a universally unified trajectory and space for signal transmission, thus reducing data corruption.

New micro potential

The final result of these micro PCB production technology advances is that designers and manufacturers face fewer obstacles in achieving microelectronic goals. This creates opportunities for greater innovation in many spaces.

For example, consider the Internet of Things. In many applications of the Internet of Things, small size is imperative. However, at the same time, devices such as sensors need to be able to operate normally for a long time, and battery life will not be a problem. Obviously, in many of these designs, the aforementioned signal strength considerations are a major factor.

But that's not all. In fact, with the miniaturization of equipment, production costs will increase significantly. For companies pursuing Internet of Things design, this may soon become a costly problem.

Micro PCB with additional technology can provide higher PCB density and install more components in a smaller space. This greatly reduces the quantity, which means that the total cost of production is much lower.

Now, the company can seek solutions for the Internet of Things when it understands that micro PCB production will not become an obstacle to ensure that its design can bring profitable equipment.

In a word, micro PCB makes microelectronic technology easier to realize, improves the quality of final products, and reduces production costs.

Future Micro PCB

In the next few years, the development trend of all microelectronics industries may continue, or even accelerate, all of which will make micro PCB manufacturing more important and important for countless electronic companies. The earlier companies move in this direction, the greater their competitive advantage will be.

The upcoming trend of the Internet of Things

We have introduced a lot about the Internet of Things, but the most important thing is that this is a huge and fast growing market with almost unlimited potential.

A large part of the attraction of the Internet of Things is that anyone can access it. In most industries, technological breakthroughs are limited to professionals and experts. The Internet of Things has expanded the competitive environment and created new opportunities for start-ups and mature enterprises. From complex high-density interconnection boards to affordable DIY computers, IoT applications can be found in various forms.

However, to make this theory a reality, the challenge of System on Chip (SoC) must be solved. SoC is essentially a microchip, and all important circuits and components can be included in a single chip, which has obvious advantages. SoC has all its advantages and is an extremely complex area. Visibility is small, and designing these extremely dense circuits is neither intuitive nor friendly. As an amateur, this technology is very complex, so it is not easy to learn by yourself or study. In addition, there are few suppliers, and they tend to cooperate with companies with reliable business volume.

This simple fact may prevent many smaller companies from pursuing IoT devices and applications, while they face the universality of the promise of IoT. After all, devices related to the Internet of Things are becoming smaller and smaller, and the required components are also getting smaller and smaller.

Micro PCB will play an important role in solving this problem. With micro PCBs, the design can become smaller without losing any visibility - every component can be encapsulated and accessed. A lower threshold for use is crucial because it helps to ensure that even organizations without rich microelectronics experience can design in this field, thereby opening the Internet of Things market to more enterprises. With the continuous expansion of the Internet of Things market, enterprises will have more and more power to enter this field. The micro PCB will make it possible to enter this space.

Another key factor is cost. Generally, as the size of electronic equipment decreases, the cost will also increase. Third, for those companies eager to try the potential provided by the developing Internet of Things market, this may be a serious obstacle to entering the company. However, with micro PCBs, designers can reduce the number of layers. The increased density can reduce the cost by 50% or more. Obviously, this is a very attractive possibility and may lead to more use of micro PCBs in the field of microelectronics (including but not limited to the Internet of Things).

Many of the points highlighted above will also lead to the extensive use of micro PCBs in another key space (wearables). A key factor in this equation is that micro PCBs will affect the battery life of wearable devices. What are the challenges and benefits of microelectronics to PCB designers explained by PCB assembly and PCB processing manufacturers?

Higher signal strength and longer battery life are one of the biggest advantages offered by micro PCBs. With the popularity of wearable devices, this benefit will become more and more obvious. This will be particularly evident as the category of "wearable devices" expands to include implantable devices. After all, the implanted device will not be able to charge, or at least very difficult to charge, which means that the battery life may be the difference between survivability and uselessness. For any company eager to enter or expand the wearable device field in the future, this will make micro PCB an absolutely necessary product.

All these factors clearly show that although micro PCBs have had an impact on microelectronics, this impact is likely to surge in the near future. In order to help your company better prepare, it provides suggestions on micro PCB design