PCB design and PCB processing manufacturers introduce how to judge the quality of circuit design and the development process of SCM.

How to judge the quality of circuit design is as follows:

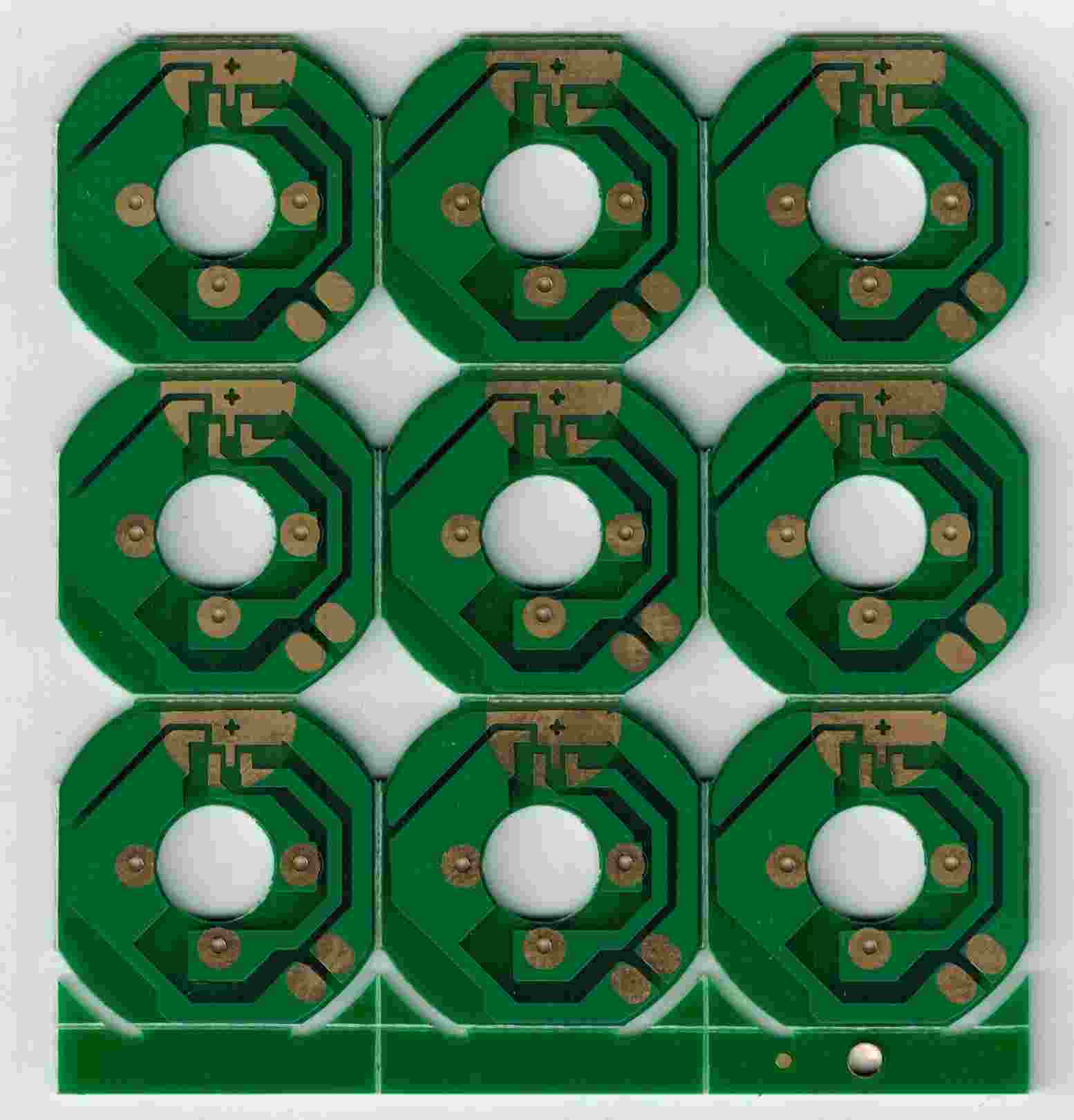

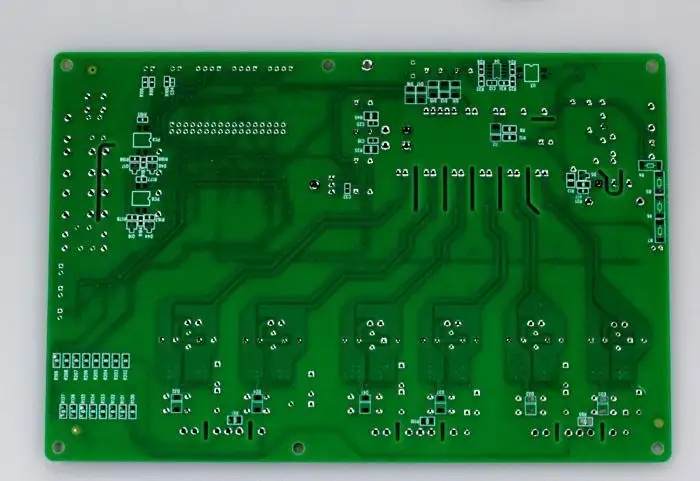

1. Standard rules for size and thickness. Customers can measure and check the thickness and specification of their products.

2. Light and color. External circuit boards are covered with ink, which can play an insulating role. If the color of the board is not bright and there is little ink, then the PCB itself is bad.

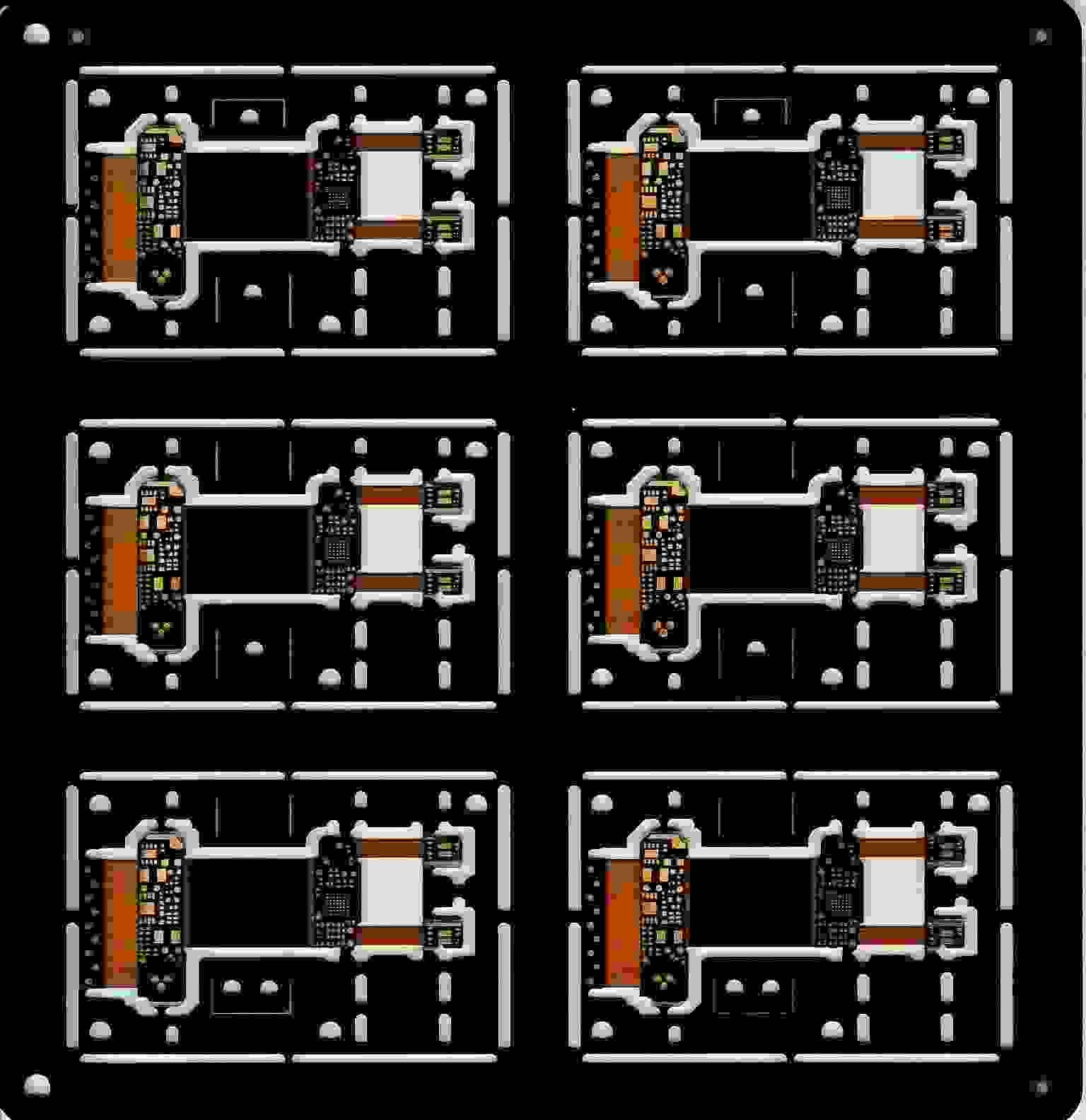

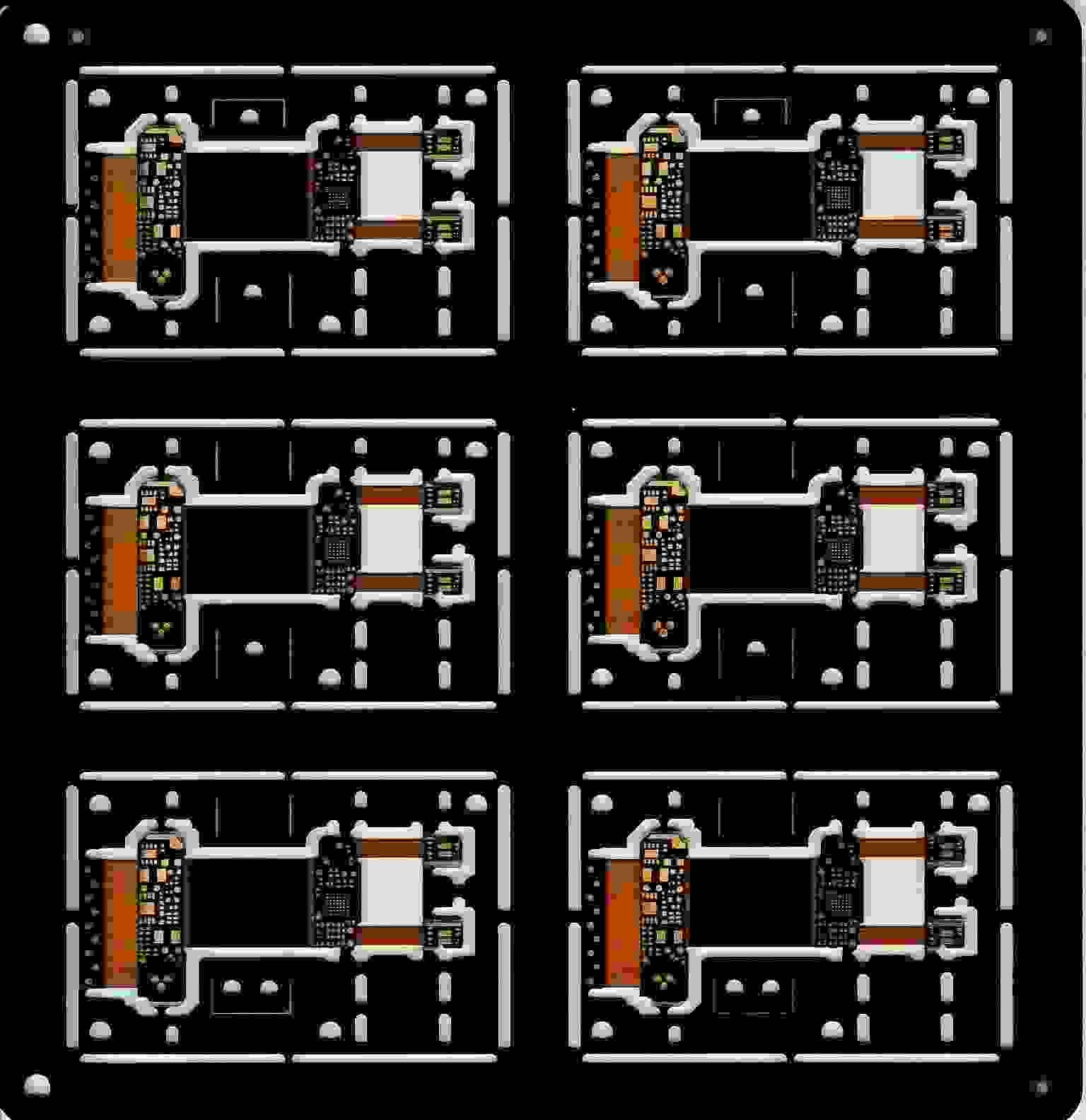

3. Weld appearance. There are many PCB parts. If the welding is not good, the parts are easy to fall off, which will seriously affect the welding quality.

4. After the components are installed, the telephone should be easy to use, that is, the electrical connection should meet the requirements.

5. The line width, line thickness and line spacing of the line shall meet the requirements to avoid heating, open circuit and short circuit of the line.

6. The copper skin is not easy to fall off under high temperature.

7. The copper surface is not easy to be oxidized, which affects the installation speed. It will be damaged soon after being oxidized.

8. No additional electromagnetic radiation.

9. The appearance is not deformed to avoid shell deformation and screw hole dislocation after installation. Now they are all mechanically installed, and the hole position of the circuit board and the deformation error of the circuit and circuit design should be within the allowable range.

10. High temperature, high humidity and special environment resistance shall also be considered.

11. The mechanical properties of the surface shall meet the installation requirements.

Single chip microcomputer development process

Direct dry goods:

1. Clarify customer needs

The primary task of the development of single chip microcomputer is to analyze and understand the overall requirements of the project, and comprehensively consider the factors such as system operating environment, reliability requirements, maintainability and product cost

2. Analyze software and hardware functions

Because the development of SCM consists of software and hardware. In the application system, some functions can be realized by hardware or software. The use of hardware can improve the real-time and reliability of the system; The software implementation can reduce the system cost and simplify the hardware structure. Therefore, in the overall consideration, it is necessary to comprehensively analyze the above factors and reasonably formulate the proportion of hardware and software tasks.

3. Determine the SCM and components required by customers

According to the needs of customers, we should select the MCU that can meet customer requirements, so as to achieve the performance and stability required by customers.

4. Circuit design

According to the design requirements and the selection of single-chip microcomputer and components, we need to design the corresponding circuit schematic diagram

5. Software Development of Single Chip Microcomputer

On the basis of system software design and circuit design, determine the program structure of the software system and divide the functional modules, and then carry out the program design of each module.

6. Simulation debugging

After the completion of software development and circuit design, it is necessary to enter the integration debugging stage of both. In order to avoid wasting resources, before generating the actual circuit board, the system simulation can be carried out by using software, and problems can be corrected in time. After completing the system simulation, use the drawing software to design the PCB according to the circuit schematic diagram, and then submit the PCB diagram to the relevant manufacturer to produce the circuit board. After getting the circuit board, in order to replace the components and modify the circuit, you can first weld the required chip socket on the circuit board, and use the programmer to write the program into the microcontroller. Next, insert the microcontroller and other chips into the corresponding chip socket, connect the power supply and other input and output devices, and conduct system joint debugging until the debugging is successful.

7. Field test and user trial

Take the tested product to the customer's application scenario, conduct on-site debugging until the customer is satisfied, and then give the product to the customer for trial. PCB design and PCB processing manufacturers introduce how to judge the quality of circuit design and the development process of SCM.