The circuit board manufacturer explains how to save circuit board design cost and how to suppress thermal interference in circuit board design.

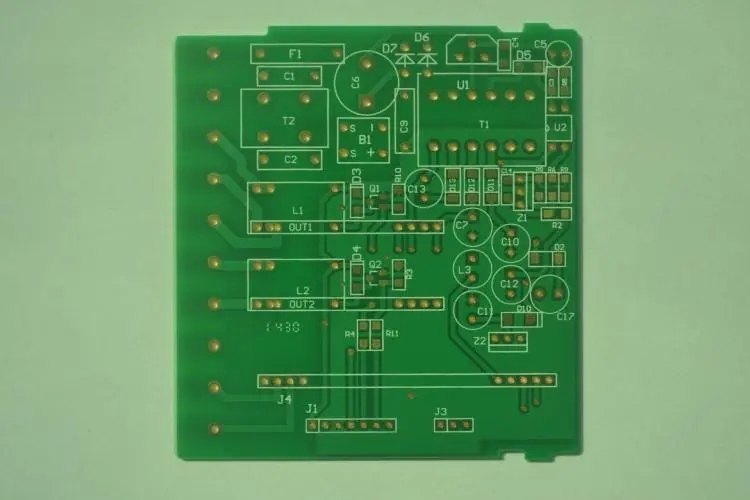

The design of printed circuit board is based on the circuit schematic diagram to realize the functions required by the circuit designer. The design of printed circuit board mainly refers to layout design, which needs to consider the layout of external connections. The optimal layout of internal electronic components, the optimal layout of metal wiring and through-hole, electromagnetic protection, heat dissipation and other factors. Excellent layout design can save production costs and achieve good circuit performance and heat dissipation. Simple layout design can be realized by hand, while complex layout design needs to be realized by computer aided design (CAD)

The size of PCB is naturally a key point. The smaller the pcb board, the lower the cost.

On the other hand, if the parts on the PCB are very dense, the wiring must be thinner and the equipment used must be of higher order. At the same time, the materials used should be more advanced, and the wire design must be more careful to avoid power consumption and other problems that may affect the circuit. The cost of these problems can save more than reducing the size of pcb board.

The higher the number of layers, the higher the cost. However, the smaller the number of layers, the larger the size.

SMT can save money than THT

Drilling takes time, so fewer pilot holes are better.

The buried hole is more expensive than the guide hole through all layers. Because the embedded hole must be drilled before jointing.

The size of holes on PCB is determined according to the diameter of part pins. If there are different types of connecting pin parts on the board, because the machine cannot use the same drill bit to drill all the holes, it is relatively time-consuming, which also means that the manufacturing cost is relatively increased.

The electronic test using the flying probe method is usually more expensive than the optical method. Generally speaking, the optical test is enough to ensure that there is no error on the PCB.

How to Suppress Thermal Interference in PCB Design

Thermal interference is an important factor that must be eliminated in PCB design. It is assumed that all components generate heat to a certain extent during operation, especially the heat generated by the high-power components will interfere with the components that are sensitive to the surrounding temperature. If the thermal interference cannot be well suppressed, the electrical performance of the entire circuit will change.

In order to suppress thermal interference, the following measures can be taken:

(1) Placement of heating elements

Do not place it on the board. It can be moved outside the enclosure, or it can be designed as a functional unit separately and placed near the edge where it is easy to dissipate heat. For example, the microcomputer power supply, the power amplifier tube pasted outside the enclosure, etc. In addition, devices with large heat generation and devices with small heat generation shall be placed separately.

(2) Placement of high-power devices

The printed board shall be arranged as close to the edge as possible and above the printed board as far as possible in the vertical direction.

(3) Placement of temperature sensitive devices

The device sensitive to temperature shall be placed in the area with the lowest temperature, and it shall not be placed directly above the heating device.

(4) Device arrangement and air flow

No specific requirements. Generally, the internal heat of the equipment is dissipated by free convection of air, so the components should be arranged in a vertical manner; If forced cooling, components can be arranged horizontally. In addition, in order to improve the heat dissipation effect, components unrelated to the circuit principle can be added to guide the heat convection.

Circuit board assembly, circuit board design and circuit board processing manufacturers explain how to save circuit board design costs and how to suppress thermal interference in circuit board design