The grounding of PCB in PCB design of PCB manufacturers

As the name implies, the package ground in PCB in PCB design is to wrap the whole signal line around the package ground.

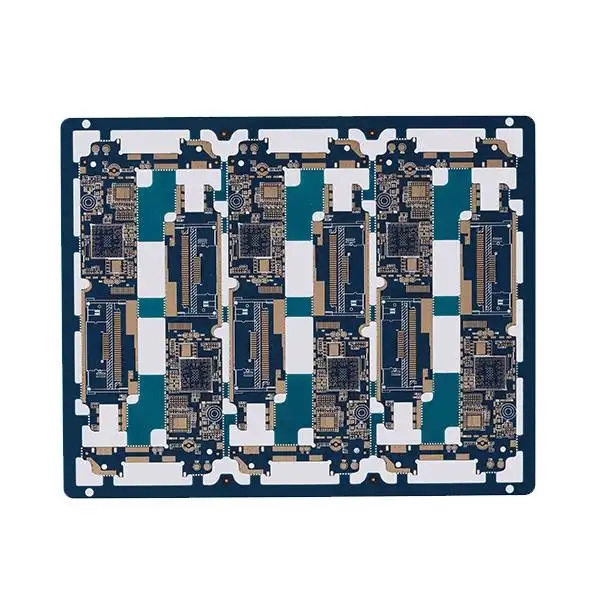

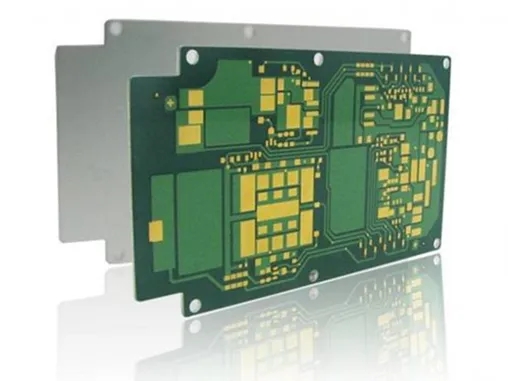

The design of printed circuit board is based on the circuit schematic diagram to realize the functions required by the circuit designer. The design of printed circuit board mainly refers to layout design, which needs to consider the layout of external connections. The optimal layout of internal electronic components, the optimal layout of metal wiring and through-hole, electromagnetic protection, heat dissipation and other factors. Excellent layout design can save production costs and achieve good circuit performance and heat dissipation. Simple layout design can be realized by hand, while complex layout design needs to be realized by computer aided design (CAD)

As the name implies, a parcel is a parcel of land around the whole signal line.

It is a problem whether the ground on both sides of the signal line is covered or not. When designing, I often see people struggling with the problem of land parcel. It may be limited by the size of the board, and it is said that the package floor can make the signal shielding better, so try to draw two thin ground wires on both sides of the important clock line differential signal. In fact, this practice increases the interference to nearby signals.

The main function of parcel land is to reduce crosstalk. What other methods can reduce the crosstalk besides the parcel ground? Increasing the signal spacing also makes the signal tightly coupled to the reference plane. If it is a multilayer board, reducing the distance between the reference plane and the signal layer can better control the impedance and make the signal tightly coupled with the reference plane, reducing the interference of the signal to nearby signals. The crosstalk can be reduced by increasing the distance between signal lines. At this time, the effect on the signal packet ground is not obvious. Especially when the space is relatively small, adding a thin ground wire is equivalent to adding a signal line between two signal lines, which acts as a bridge to transmit the signal interference to the next signal. It should be better to remove this ground wire to reduce crosstalk.

Some people say that not only do we need to add ground wire to wrap the ground, but also make more holes on the ground wire. Of course, the effect will be better. But since the floor hole can be punched, it means that the minimum line width of the parcel ground should be more than ten mils. With the line spacing, the original distance between the two signal lines is enough to meet the requirements of 4W. In this way, the crosstalk itself is very small, and it will not increase much if the parcel ground signal is removed.

If it is a two-layer board with no reference plane, the package ground of important signals is very important. The width of the cladding wire should be as wide as possible, preferably more than twice the signal width. At the same time, more vias shall be drilled, and the vias spacing shall be less than 1/5 of the signal wavelength on the signal line.

In some non high frequency SCM wiring, crystal oscillator, serial port, important signal line, interrupt signal, etc. are processed by package.

The RF analog signal package is common, which can effectively improve the signal quality. The minimum loop is provided artificially, and shielding is added. PCB processing, PCB assembly, PCB design, PCBA manufacturers will introduce the PCB packaging in PCB design.

The ground covered hole of aberration is definitely beneficial. It has been verified by simulation and can improve the impedance drop at the layer change. The enclosure of PCB in the circuit board design of the circuit board manufacturer.