How to solve the problem of dirty PCB?

Printed circuit boards accumulate dust, which may occasionally come into contact with liquid by splashing or soaking Contact with these components will gradually corrode the solder joints and damage the circuit

A large number of pollutants can also isolate the small components on the circuit board, prevent heat loss, and eventually overheat them.

This article explains how dirty boards affect projects and how to clean them. This must help you.

What does it mean that the circuit board is dirty?

"Dirty circuit boards" are sometimes used in the market to refer to second-hand or refurbished circuit boards, which are purchased as cheap substitutes for new circuit boards.

The circuit board cleaning company has carried out adequate maintenance on the circuit boards used in the previous equipment, which can be used as the standard for manufacturing new equipment.

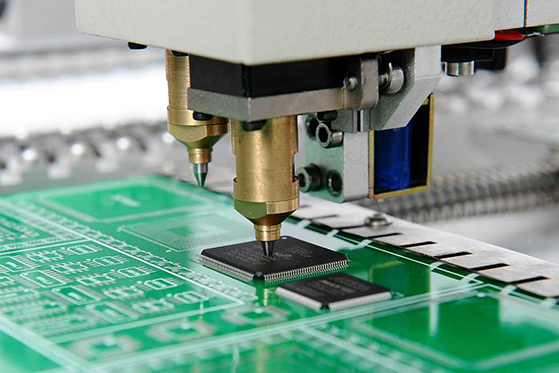

Circuit board

Despite the name, on the surface, market grade dirty circuit boards are usually very clean. However, although high-quality dirty circuit boards can maintain their functions for a long time, they cannot guarantee the life of new circuit boards.

This, ready-made dirty circuit board is very suitable for prototype.

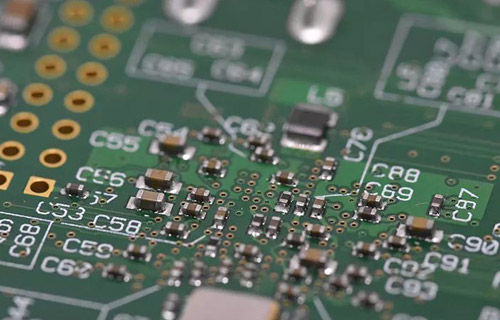

If a large amount of flux residue is left after PCB welding, the circuit board can also be regarded as "dirty" Today, about 70% of printed boards are assembled without clean solder paste In short, this means that there is no need to remove the flux

However, after welding, the flux usually leaves some residues on and around the solder joint. The amount of residue depends on the content of solid resin, gelling agent and activator of the flux. The flux with very low solid content leaves few residues on the circuit board.

How dirty circuit boards affect work

Circuit board contaminants such as dust, moisture, and flux residues can adversely affect the circuit.

2.1 Dust and moisture

Dust is a complex substance, which is composed of different inorganic and organic materials, as well as a large amount of water and dissolved salts.

Due to the increasing use of miniaturization technology and circuit boards in dusty environments (such as telecommunications and information industries), dust has an increasing impact on the reliability of circuit boards.

Dust can cause many problems with the circuit board. Because of its hydrophilicity, it can form a conductive electrolyte film, thus damaging the surface insulation resistance between conductors.

Even without water, these particles will increase the friction of the contact surface, thus promoting wear and corrosion. In addition, because they act as dielectrics, they may also cause signal interference in connectors and wiring.

If all this is not enough to prompt you to finally check the electronic equipment, the dust accumulated on the active components and power connectors may cause irreversible damage when the components overheat.

2.2 Flux residue

Although dust and moisture are bad for the circuit board, flux residues may have a worse impact on the project. The information of no cleaning flux is introduced to eliminate the need to clean the circuit board before re welding.

However, despite the obvious benefits of not having clean panels, the assembler quickly realized the residual problem.

Flux residues that fall off from the circuit board during PCB soldering tend to accumulate on the pins of the soldered components, causing conductivity problems, especially in circuits with clock speeds exceeding 1 GHz.

At such a high frequency, electrons mainly conduct on the outer surface of the conductor, which means that the residual magnetic flux on the terminal will conduct current and cause signal interference.

Like dust, PCB flux residues are hydrophilic Therefore, when the bottom filling material is distributed in the flip chip assembly and heated for curing, a small pocket or steam or gas will be formed, which will eventually separate the bottom filling material from the circuit board, thus providing a channel for pollutants to enter the PCB assembly