Introduction to PCB Multilayer Cell

A circuit with more than two layers is called a multilayer circuit board Therefore, this means that the minimum number of layers of a multilayer circuit board is 3. It is not easy to stack data together, but it is necessary for a multilayer pool

There should be no air entrapment between PCB multilayer tanks. Eagle circuit board design software is indispensable in the manufacturing of multi-layer pool.

This process is very complex, usually starting with the preparation of the schematic diagram. Then use the Editor menu on the Eagle software to edit the footprint.

You may wonder why most circuit board layers are unified. It should be noted that preparing even layers is more cost-effective than preparing odd layers. This is the reason for the uniformity of the layer.

1. Multilayer circuit board

In the manufacturing of multilayer circuit boards, both core data and prepreg are used for manufacturing layers. Prepreg are those uncured materials, which means they are plastic.

Then, the prepreg and the substitute materials of the core material are laminated together under high temperature and high pressure to make the prepreg become a kind of material. After cooling, the layers are joined together to form a hard and firm multilayer board.

Circuit board

Note that multilayer boards have a wide range of advantages, including:

New flexibility

Higher assembly density

Controlled impedance characteristics

Small volume

With electromagnetic interference mask

It eliminates the need for interconnecting harnesses, reducing overall weight

2. Multi layer tank process

Multiple PCB manufacturing process involves using Eagle software to design circuit boards This is a complex process, starting from the completion of the schematic diagram The schematic diagram is edited through the editor menu of Eagle software

3. Multilayer pool

After designing and drawing the schematic diagram, the next thing to do is layout; This can be achieved by importing the size of the printed circuit board and uploading it to the software.

If you use Eagle software, you will have the opportunity to select the appropriate grid to help each circuit board layer overlap. This can be done through a button that routes each layer according to your needs.

Alternatively, you can use Eagle software to automatically create a multi tier board pool. However, if you choose this technology, you need to cross check components, text, layers, and dimensions.

You should then use the check rule option to evaluate the final layout.

4. Multilayer circuit board

Multilayer printed circuit board has become the core of electronic products in the world. They are the basic functions of components and wiring; This makes the new circuit board more advanced and complex.

It provides end users with advanced flexible options and weird varieties to choose from. The circuit board used in simple electronic products is composed of single layers, while the complex circuit board used in the main computer board is multi-layer; This is why they are called multilayer circuit boards.

It should be noted that advanced technology enables manufacturers to significantly reduce the size of circuit boards.

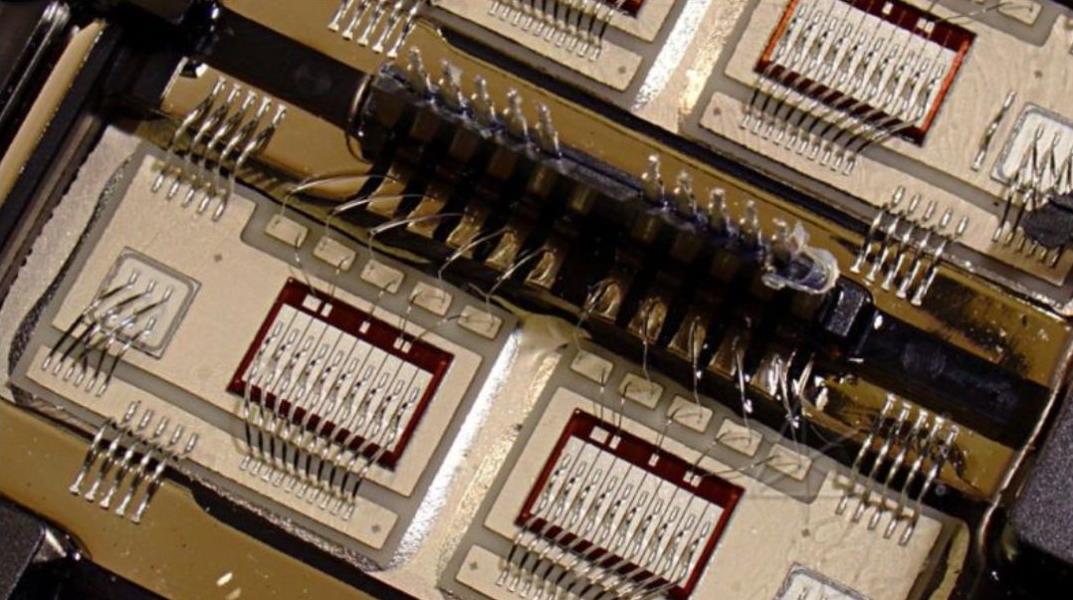

Multilayer circuit board is a circuit board made of at least three layers of copper foil. They look like several single-sided or double-sided circuit boards, which are stuck together with heat insulation and protective insulation adhesive. These two layers are usually placed on the surface side of the circuit board.

The electrical connection between the layers is realized through such vias as embedded holes and electroplated through holes; This has led to a generation of complex circuit boards with different sizes on the market.

Multilayer circuit boards were discovered through changes in the electronic world. Their continuous use and functions in the modern electronic world make them more complex and complex.

At first, the circuit board had its own problems, including crosstalk, capacitance and noise. Recall that the manufacturer must impose specific constraints to limit the problem.

Design considerations mean that careful design can achieve high-performance circuit boards, such as double-sided circuit boards. It is this understanding that led to the discovery of multilayer circuit boards.

It allows multilayer circuit boards to be packaged into small sizes to meet the growing demand for electronic products.

Modern circuit boards have different layers ranging from 4 to 12 layers. The number of sheets is even to reduce warpage and other problems related to odd numbered layers.

In addition, generating an even number of layers is cost-effective compared to building a different number of layers.

In addition, most modern devices, including smartphones and mobile devices, use 12 page circuit boards. Some manufacturers can make about 32 layers of circuit boards.

Please note that while manufacturing multilayer boards requires a lot of labor and cost, they are becoming increasingly important in the modern world.

The reason is that they have many advantages over double-layer or single-layer circuit boards.

5. Advantages of Multilayer PCB

They are small; This is the best feature of multilayer circuit boards. They are smaller than single-layer or double-layer circuit boards, which is very beneficial to the current trend.

They are more compact and robust, and are widely used in notebook computers, smartphones and tablets. Lightweight construction.

Smaller boards are lighter because they do not use the multiple connectors needed to interconnect them to double-layer and single-layer boards. This adds mobility to the application device.

High quality. The creation of multilayer boards requires proper planning and organization, which means that the result will be a better quality product than double-layer or single-layer boards. In addition, these boards are more reliable.

Improve durability. The multilayer circuit board is durable. They can bear a lot of weight, and can withstand the heat and pressure that are always exerted on them during the binding process. They also have multilayer insulating materials and prepreg between layers to improve their durability.

Highly flexible. Circuit board assemblers using flexible construction technology finally obtain flexible multilayer circuit boards with very ideal characteristics, such as being able to be applied to areas requiring deflection and bending. However, it should be noted that the more layers used in a circuit board, the less flexible it is.

More powerful. Multilayer circuit boards combine many layers into a single unit circuit board. They make circuit boards have stronger connectivity, and give them some characteristics, so that they can achieve higher speed and capacity, even if they are small in size.

Single connection point Multilayer PCBs work in a single cell, so they always have only one connection point This is not the case when you use multilayer single-layer or double-layer circuit boards This is of great benefit to the electronic world because it helps minimize size and weight