How to judge PCB quality

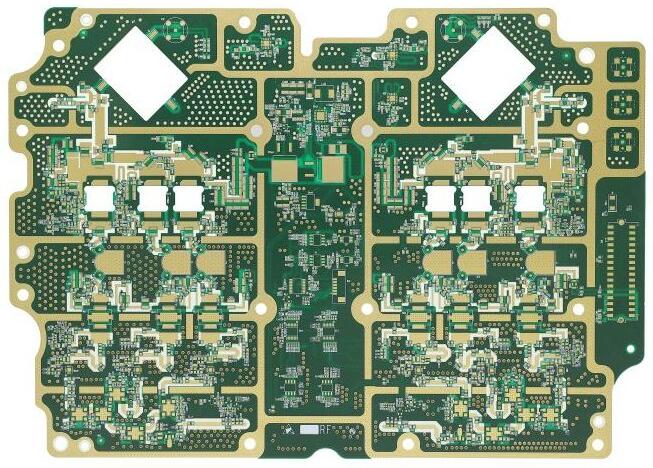

1. The raw material of PCB is very common in our life. It is composed of glass fiber and resin. The two are combined and hardened to form a kind of heat insulation, insulation, and not easy to bend plate. This is the circuit board substrate. In general, for example, the PCB board composed of glass fiber and resin alone cannot transmit signals, so we will cover the surface with a layer of copper. Therefore, we also call the PCB board copper clad circuit board.

2. PCB mainly provides interconnection between electronic components. Color is not directly related to its performance. Different colors will not affect the electrical performance The performance of a circuit board is determined by the materials used, the layout and the number of layers of the board. However, in the process of making PCB, black is the most likely to cause color difference. If there is a slight deviation between the raw materials used by PCB manufacturers and the manufacturing process, the defective rate of PCBA will increase due to color difference. This will increase production costs.

3. Because the circuit routing of black PCB is difficult to identify, it will increase the difficulty of maintenance and debugging in the R&D and after-sales stages. Generally, black PCB will not be used without the brand of skilled RD (R&D) designers and powerful maintenance teams. It can be said that the use of black PCB is a sign that a brand has confidence in RD design and post maintenance teams. From the side, it is also a reflection of the confidence of PCB manufacturers in their own strength.

How to debug a problem circuit board

Modulation Skill 1: Circuit board voltage measurement method:

In this method, we first need to use the instrument to confirm whether the voltage value of each chip power supply pin on the circuit board is within the normal range, and also need to test the working voltage value of the point to see whether its value is within the normal range. For example, in general, when the silicon triode is energized, the BE junction voltage is about 0.7V, while the CE junction voltage is about 0.3V or less. If the voltage value at the BE junction of the triode is found to be greater than 0.7V during the test (except for special triodes, such as Darlington tubes, etc.), it may be that the BE junction has an open circuit.

Debugging method 2: signal injection method of circuit board:

The principle of this method is to add the signal source to the input terminal, and then measure the waveform of each point in turn to see if it is normal, so as to find the fault point. Sometimes we also use simpler methods, such as holding a pair of tweezers to touch the input terminals at all levels to see if the output terminals respond, which is often used in audio, video and other amplification circuits. If there is no reaction at the first level before the collision, but there is reaction at the second level after the collision, it indicates that the problem is at the first level, and the inspection shall be focused

Debugging method 3: Circuit board debugging method:

Look, listen, smell and feel: it is through observing that the surface of the circuit board is obviously damaged by machinery, such as deformation, fracture and other related conditions. Listen: It is to carefully distinguish the working sound of the circuit board from the sound at normal time to determine the problem. Smell: It is to check whether there is the smell of burning on the circuit board, the smell of capacitor electrolyte, etc. This situation is very sensitive to these smells for an experienced circuit board maintenance personnel. Touch: It means to feel that the problems of the components of the circuit board are within the normal temperature range by hand. Generally, the components of the circuit board will heat up after working. If there is no heat, it means that the components do not work normally, but it also heats up in places that cannot be heated, which also means that the circuit board has a fault, Working below 70 degrees is totally OK. If this problem is exceeded, problems will arise. In addition to debugging certain instruments, the adjustment of the circuit board requires long-term accumulation of experience in circuit board maintenance. Only through long-term accumulation can the circuit PCB board be adjusted in the shortest time, so that the circuit board can resume normal operation.