PCBA "three prevention" process design explanation

PCB environmental protection three proofing paint belongs to a kind of one component, low viscosity resin light milky white protective paint liquid, which is prepared from resin polymer compound.

PCB environmental protection three proofing paint has outstanding "moisture-proof", "salt fog proof" and "mildew proof" performance, which can effectively isolate the circuit board and protect the circuit from the corrosion and damage of harsh environment.

Strong adhesion, low stress, no corrosion to components, wide temperature range, high softening point of paint film. The product has good stability to acid, alkali, salt and other chemicals, and becomes a transparent protective film after curing.

It has excellent salt spray resistance, mold resistance and moisture resistance, and has the characteristics of rapid film formation, insulation, moisture-proof, anti leakage, shockproof, dust-proof, anti-corrosion, mold resistance, anti loose parts and coverage confidentiality, strong oxidation resistance, thermal stability, anti-aging, and can withstand the corrosion of acids, alkalis, and salts of various concentrations.

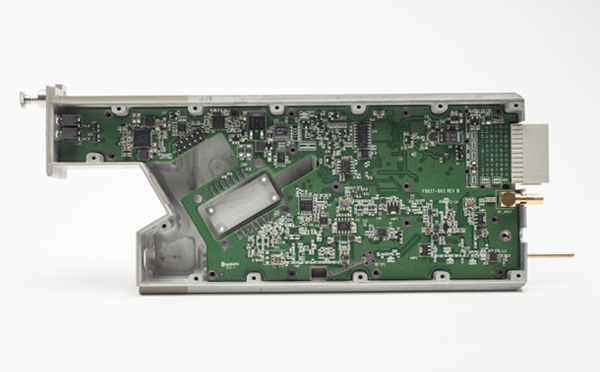

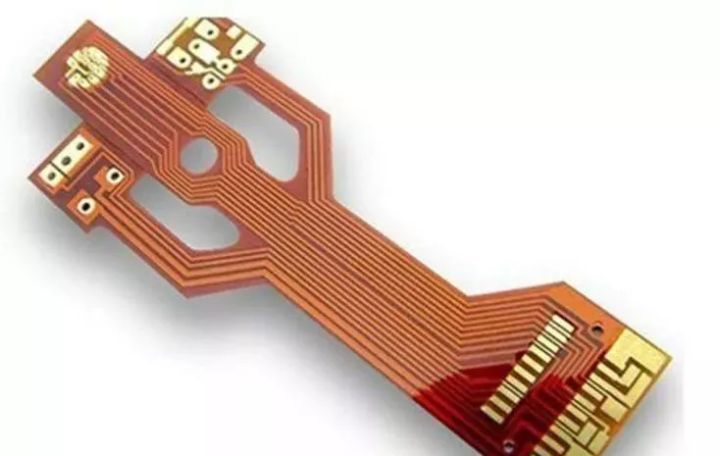

Three proofing paint for circuit board is a transparent protective paint with waterproof, insulation and solvent resistance, which is made of a variety of new composite materials. It is the best PCB and LED covering protection product in the field of small household appliances. It is also widely used in the preferred protection products for electronic parts such as hybrid integrated circuits, automobile electronic control boards, electronic circuit boards, soft printed circuit boards, computer control boards, industrial control boards, semiconductor crystal circuit protection, etc.

The circuit board three proofing paint has outstanding "moisture proof", "salt fog proof" and "mold proof" properties, which can effectively isolate the circuit board and protect the circuit from the corrosion and damage of harsh environment.

Good adhesion, low stress, no corrosion to components, wide temperature range, high softening point of paint film. After curing, it forms a transparent protective film.

It has excellent insulation, moisture-proof, anti leakage, shock proof, dust-proof, anti-corrosion, mildew proof, anti loosening of parts and covering confidentiality performance, strong oxidation resistance, thermal stability, anti-aging, and can withstand the corrosion of various concentrations of acid, alkali, salt; It can be cured at room temperature or low temperature, with dense and bright paint film and strong adhesion.

Background:

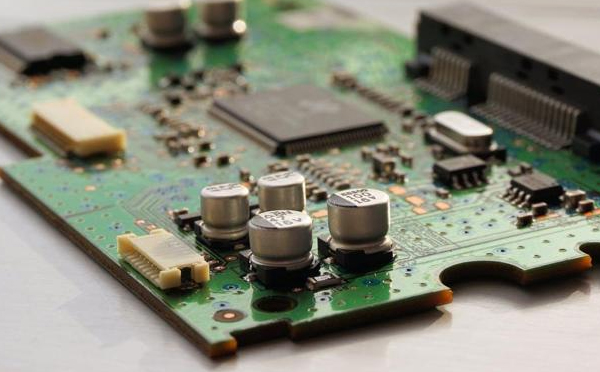

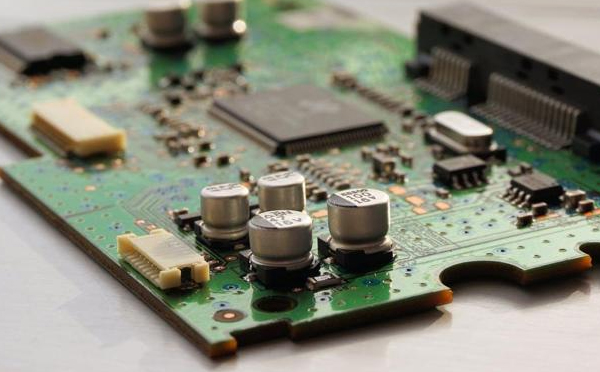

The essence of "three prevention" in electronic processing is to apply a layer of protective film on the protected surface. The protective effect is related to the coating method and coating process. Spraying is basically the protection of PCB surface, while dip coating can protect components. Due to the fluidity of the coating and the unevenness of the PCB surface, the corresponding relationship between the coating times and the "three prevention" effect is determined.

"Three prevention" process design requirements:

The "three prevention" process is related to the design requirements.

(1) If only to improve the insulation level and corrosion resistance of the PCB surface, the process of directly spraying one coat on the surface of the wash free welding PCBA can be adopted.

(2) If effective "three prevention" protection is required, the coating must be carried out in strict accordance with the "three prevention" process requirements.

Protect the components.

Immersion treatment or potting for transformers, coils, etc; Solid protective film is applied to the plug-in; Special treatment shall be carried out for components.

Clean and dry the PCB.

There are still a lot of rosin film residues in the wash free flux. On the one hand, it will react with the three proofing paint to form pinholes. On the other hand, it will crystallize and expand after moisture absorption, which will eventually cause the three process design anti coating to fall off. Therefore, if a better three proofing is required, it must be cleaned.

Must be applied twice.

Spraying, especially using paint containing solvent, will cause pinholes after the paint film is cured. In order to achieve a better moisture barrier level, it must be sprayed twice, which is also one of the effective measures to ensure the coating thickness on the line. The minimum coating thickness on general lines shall be at least 25 μ Above m (non lines actually exceed this standard, generally "25~225 μ m”)。 Note: The effect of "three prevention" is related to the number of spraying times and the thickness of paint film.

(3) For offshore equipment, the most effective measure is to use sealed cabinets, which is the most important measure. The "three proofing" treatment of PCB alone has no effect.

"Three proofing" mainly improves the anti-corrosion level of PCB - covering exposed Cu, isolating corrosive gas and moisture in the air. As long as it can destroy the conditions of sulfuration, electromigration, electrochemical corrosion and chemical corrosion, it can achieve the goal.

The core of "three proofing" process: three proofing paint, process and film thickness. The effect of "three proofing" depends on the film thickness.

It should be pointed out that the "three precautions" only delay moisture absorption and cannot completely prevent moisture. If waterproof and dustproof are required, the potting process shall be adopted.