What is the FR4 material in PCB

What is FR-4?

FR-4 material, which is the abbreviation of glass fiber cloth, is a kind of circuit board raw material and base material, the code name of flame-resistant material grade, which means that the resin material must be able to extinguish itself after burning. A material specification. Most commonly used in PCB (printed circuit board), general single-sided, double-sided and multi-layer PCB circuit boards are made of this! Because of its high strength and flame retardancy, most circuit boards will choose FR-4 as the base material.

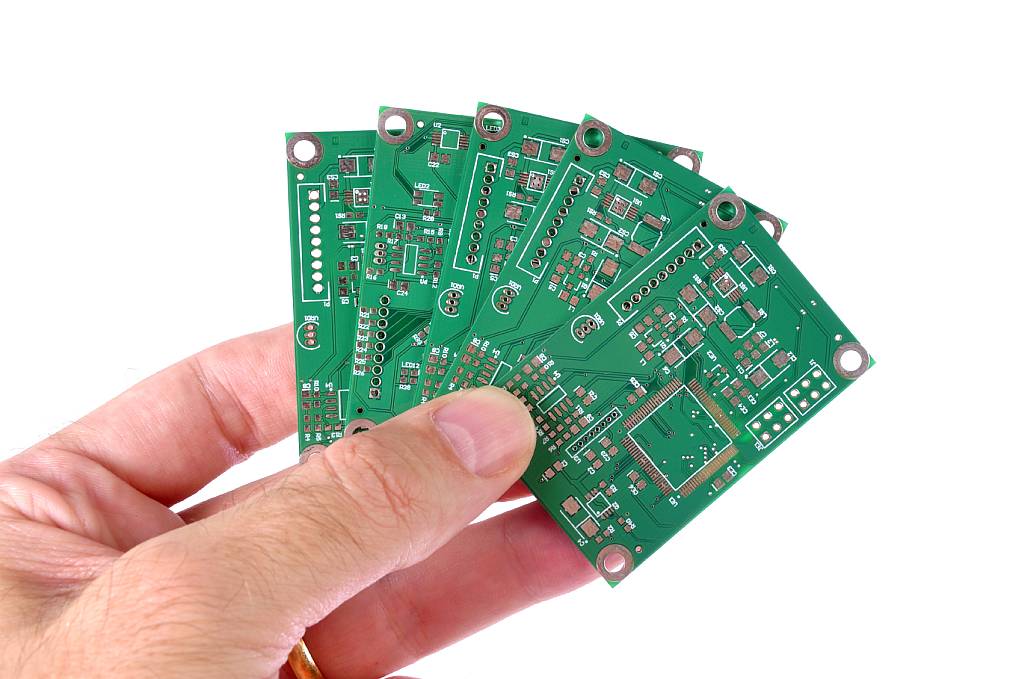

2. What is a PCB and its composition?

PCB is the abbreviation of Printed Circuit Board in English. The Chinese name is printed circuit board, also known as printed circuit board and printed circuit board. It is an important electronic component. It is a provider of electrical connections for electronic components.

A PCB starts with the most basic unit: the substrate, which consists of several layers, each of which plays an important role in the functionality of the final PCB. These alternating layers include:

• Substrate: This is the base material of the PCB. It makes the PCB rigid.

• Copper: Add a thin layer of conductive copper foil to each functional side of the PCB - on one side if it is a single-sided PCB, or on both sides if it is a double-sided PCB. This is the copper trace layer.

• Solder mask: On top of the copper layers is the solder mask, which gives each PCB its characteristic green color. It brings copper traces into inadvertent contact with other conductive materials that could cause a short circuit. In other words, the solder keeps everything in place. The holes in the solder mask are where the solder is applied to connect the component to the board. Solder mask is a critical step for smooth PCBA manufacturing as it prevents soldering on unwanted parts and avoids short circuits.

• Silkscreen: The white silkscreen is the last layer on the PCB. This layer adds labels on the PCB in the form of characters and symbols. This helps give an indication of the function of each component on the board.

PCBs vary according to their substrate materials, such as high-frequency microwave boards, metal substrates, aluminum substrates, iron substrates, copper substrates, double-sided boards and multi-layer boards. The circuit is used as a tool for conducting between components, and a large copper surface is additionally designed as a grounding and power supply layer in the design. Lines and drawings are made at the same time. The wiring density is high, the volume is small, and the weight is light, which is conducive to the miniaturization of electronic equipment.

The substrate of the board itself is made of insulating and heat-insulating materials that are not easily bent. The small circuit material that can be seen on the surface is copper foil. Originally, the copper foil covered the entire board, but part of it was etched away during the manufacturing process, and the remaining part became a network of small circuits. .

3. Advantages and characteristics of FR-4.

General single-sided, double-sided and multi-layer PCB circuit boards are made of FR-4, FR in FR-4 means flame retardant, and the number 4 distinguishes the material from other materials in this category. FR-4 is a fiberglass reinforced epoxy laminate that looks like a thin woven cloth panel. The term FR-4 also stands for the grade used to make these laminates. The fiberglass structure provides structural stability to the material. Fiberglass layers are covered with flame retardant epoxy resin. This brings durability and strong mechanical properties to the material. All of these features make FR-4 printed circuit boards popular among electronics contract manufacturers.

Its technical features mainly lie in: electrical insulation, stable performance, good flatness, smooth surface, no pits, standard thickness tolerance, suitable for products that require high-performance electronic insulation, such as FPC reinforcement boards, PCB drilling backing boards , glass fiber meson, potentiometer carbon film printed glass fiber board, precision planetary gear (wafer grinding), precision test plate, electrical (electrical) equipment insulation stay partition, insulation backing plate, transformer insulation board, motor insulation, grinding Gears, electronic switch insulation boards, etc.

FR-4 sheet has been widely used in electronic products such as military industry, communication, computer, digital circuit, industrial instrumentation, automobile circuit, etc., and all performance indicators can meet the needs of general industrial electronic products. There is a very good price-performance ratio.

Example: industrial battery circuit board

Plate type: FR-4

Layers: 2 layers

Plate thickness: 1.6mm

Size: 80mm*300mm

Surface treatment: white character green finish

FR-4

FR-4, one of the commonly used substrates for PCB, is a code name for a flame-resistant material grade, which means a material specification that the resin material must be able to extinguish itself after burning. FR-4 is not a material designation, but a material grade.

FR-4 is generally divided into:

FR-4 rigid board, common board thickness 0.8-3.2mm;

FR-4 thin plate, the common plate thickness is less than 0.78mm.

The general technical indicators of FR-4 sheets are: bending strength, peel strength, thermal shock performance, flame retardancy, volume resistivity, surface resistance, dielectric constant, dielectric loss tangent, glass transition temperature Tg, dimensional stability , maximum operating temperature, warpage, etc.

Knowledge expansion: PCB material classification

1. Glass cloth substrate: FR-4, FR-5

It is a plate-shaped pressed product made of special electronic cloth impregnated with epoxy novolac epoxy resin through high temperature, high pressure and hot pressing.

Epoxy glass fiber cloth substrate (commonly known as: epoxy board, glass fiber board, fiber board, FR4). Epoxy glass fiber substrate is a kind of substrate with epoxy resin as adhesive and electronic grade glass fiber cloth as reinforcement material.

Epoxy glass fiber cloth copper clad laminate has high strength, good heat resistance, good dielectric properties, and the through hole of the substrate can be metallized to realize the circuit conduction between double-sided multi-layer printing layers and layers. Epoxy glass fiber cloth copper clad laminate It is the most widely used and the most used type among all the qualities of copper clad laminates.

▲PCB base material selection diagram (source: source "GJB 4057-2000 Military Electronic Equipment Printed Circuit Board Design Requirements")

2. Paper substrate: FR-1, FR-2, FR-3, etc.

The phenolic paper substrate uses phenolic resin as the adhesive and wood pulp fiber cloth as the surface reinforcement material.

3. Composite substrate: CEM-1 and CEM-3

This type of substrate is mainly CEM series copper clad laminates, among which CEM-1 (epoxy paper-based core material) and CEM-3 (epoxy glass non-woven fabric core material) are two important varieties of CEM. CEM series boards have good processability, flatness, dimensional stability, and thickness accuracy. Its mechanical strength, dielectric properties, water absorption, and metal migration resistance are all higher than those of paper substrates, while the mechanical strength (CEM-3) About 80% of FR-4, the price is lower than FR-4 board.