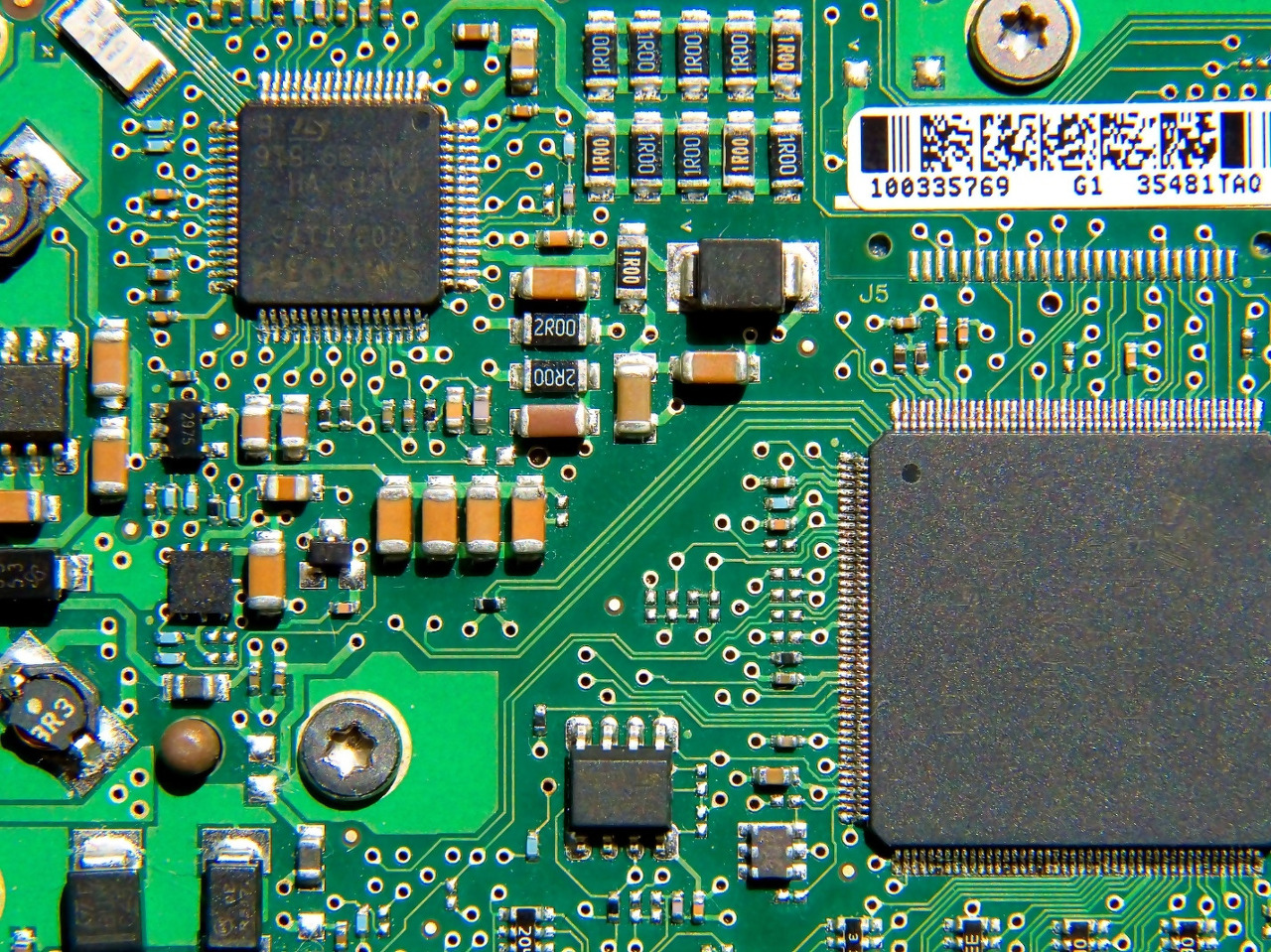

With the miniaturization and high function of electronic equipment, high heating is generated, and the thermal management requirements of electronic equipment are increasing. One of the solutions chosen is the development of thermal conductive printed circuit boards. Heat and heat dissipation of PCB is the primary condition of substrate heat resistance and heat dissipation. At present, the heat resistance and heat dissipation of substrate are improved to a certain extent by resin improvement and filler, but the improvement of thermal conductivity is very limited. Typical is the use of metal substrate (IMS) or metal core printed circuit board, to play the role of heat dissipation components, than the traditional radiator, fan cooling to reduce the size and cost.

Aluminum is a very attractive material, it is rich in resources, low cost, good thermal conductivity and strength, and environmentally friendly, metal substrate or metal core is mostly metal aluminum. Aluminum based circuit board has the advantages of simple economy, reliable electronic connection, high thermal conductivity and strength, welding and lead-free environmental protection, from consumer goods to automobiles, military and aerospace can be designed and applied. There is no doubt about the thermal conductivity and heat resistance of metal substrate, the key lies in the performance of the insulating binder between metal plate and circuit layer.

At present, the driving force of thermal management focuses on LED. Nearly 80% of the input power of LED is converted into heat. Therefore, the thermal management problem of LED is highly valued, with the focus on the heat dissipation of LED substrate. The composition of high heat resistance and environmental protection heat insulation layer materials lays the foundation for entering into the high brightness LED lighting market.

Flexible and printed electronics and other requirements

Flexible plate requirements

The miniaturization and thinness of electronic equipment inevitably use flexible printed circuit board (FPCB) and rigid flexible combined printed circuit board (R-FPCB). The global FPCB market is currently estimated at approximately $13 billion and is expected to grow at a higher annual rate than rigid PCBS.

With the expansion of applications, there will be many new performance requirements in addition to the increasing number of applications. Polyimide membrane has colorless transparent, white, black and yellow and other different kinds, with high heat resistance and low CTE performance, to suit different occasions. There is also a market for cost-effective mylar substrates, where new performance challenges include high elasticity, dimensional stability, film surface quality, as well as the film's photocoupling and environmental resistance to meet the changing requirements of end users.

FPCB and rigid HDI board to adapt to high speed and high frequency signal transmission requirements, the dielectric constant and dielectric loss of flexible substrate must also be paid attention to, using polytetrafluoroethylene and advanced polyimide substrate to form flexible circuit. By adding inorganic powder and carbon fiber filler to polyimide resin, a three-layer flexible thermal conductive substrate can be produced. Inorganic fillers are aluminum nitride (AlN), alumina (Al2O3) and hexagonal boron nitride (HBN). The substrate has thermal conductivity of 1.51W/mK, can withstand 2.5kV voltage resistance, 180 degree bending test.

FPCB application markets such as smart phones, wearable devices, medical devices, robots, etc., put forward new requirements for the performance structure of FPCB, and developed new products of FPCB. Such as ultra-thin flexible multilayer board, four-layer FPCB from the conventional 0.4mm thin to about 0.2mm; High-speed transmission flexible plate, using low Dk and low Df polyimide substrate, to meet the transmission speed requirements of 5Gbps; High power flexible plate, using 100μm thick conductor, to meet the needs of high power and large current circuit; High heat dissipation metal base flexible plate is the local use of metal plate substrate R-FPCB; The tactile sensing flexible plate consists of a pressure sensing film and an electrode sandwiched between two polyimide films to form a flexible tactile sensor; Stretchable flexible plate or rigid flexible bonded plate, the flexible substrate is elastomer, the shape of the metal wire pattern is improved to be stretchable. These special FPCBS, of course, require unconventional substrates.

Printed electronics requirement

Printed electronics have been booming in recent years, with a projected market of over $300 billion by the mid-2020s. Printed electronic technology applied to printed circuit industry, is a part of printed circuit technology, this has been a consensus in the industry. Printed electronics is the closest technology to FPCB. Now PCB manufacturers have put into printed electronics. They start with flexible boards and replace printed circuit boards (PCB) with printed electronic circuits (PEC). At present, there are many substrates and ink materials, once the performance and cost breakthrough will be a large number of applications, PCB manufacturers do not miss the opportunity.

Printed electronics currently focuses on low-cost manufacturing of radio frequency identification (RFID) tags that can be printed in rolls. Potential areas are printed displays, lighting and organic photovoltaics. The wearable technology market is a favorable emerging market. Wearable technology A variety of products, such as smart clothing and smart sports glasses, activity monitors, sleep sensors, smart watches, enhanced fidelity headphones, navigation compass and so on. Flexible electronic circuits are indispensable for wearable technology devices, which will drive the development of flexible printed electronic circuits.

One important aspect of printed electronics is materials, including substrates and functional inks. Flexible substrate in addition to the existing FPCB application, also developed higher performance substrate, currently there are high dielectric substrate materials composed of ceramic and polymer resin mixture, as well as high temperature substrate, low temperature substrate and colorless transparent substrate, yellow substrate, etc.