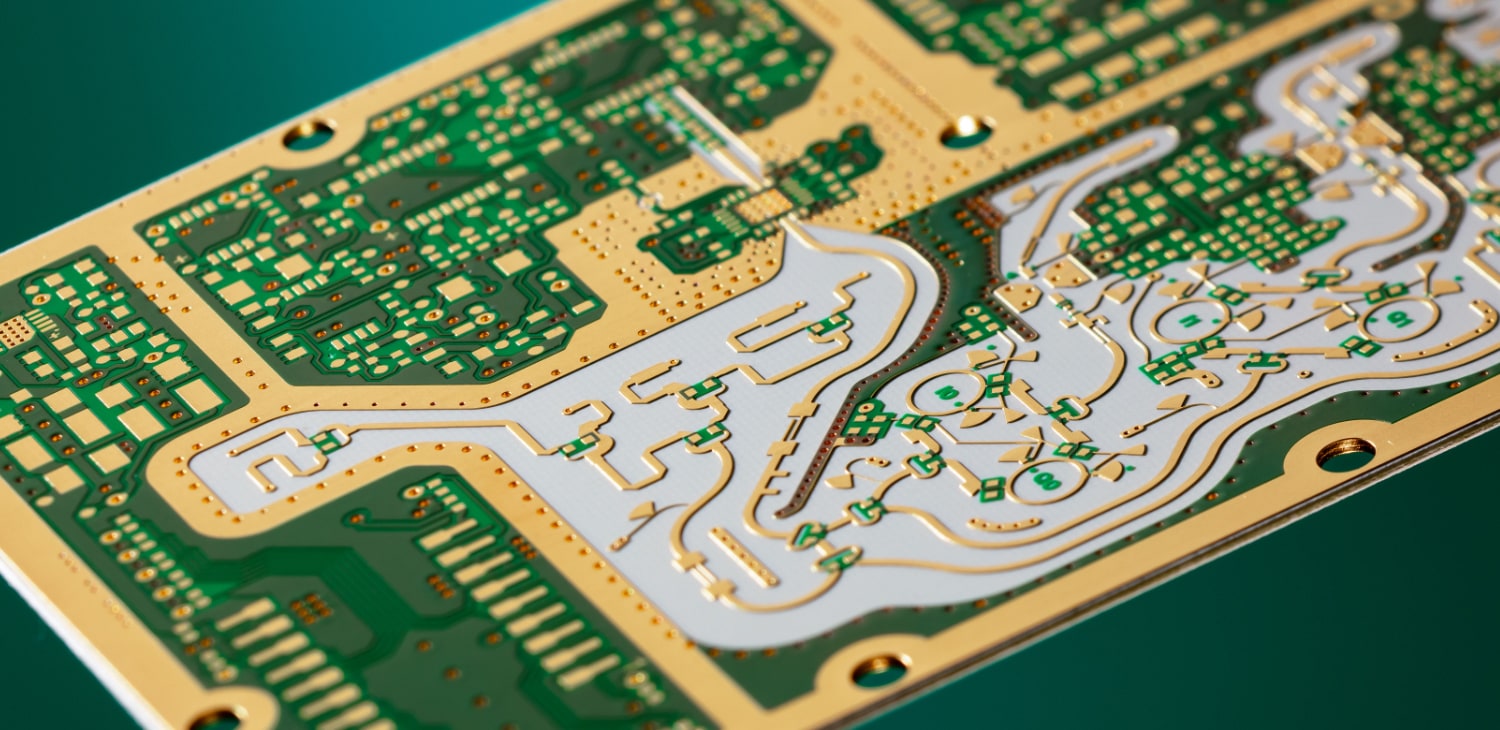

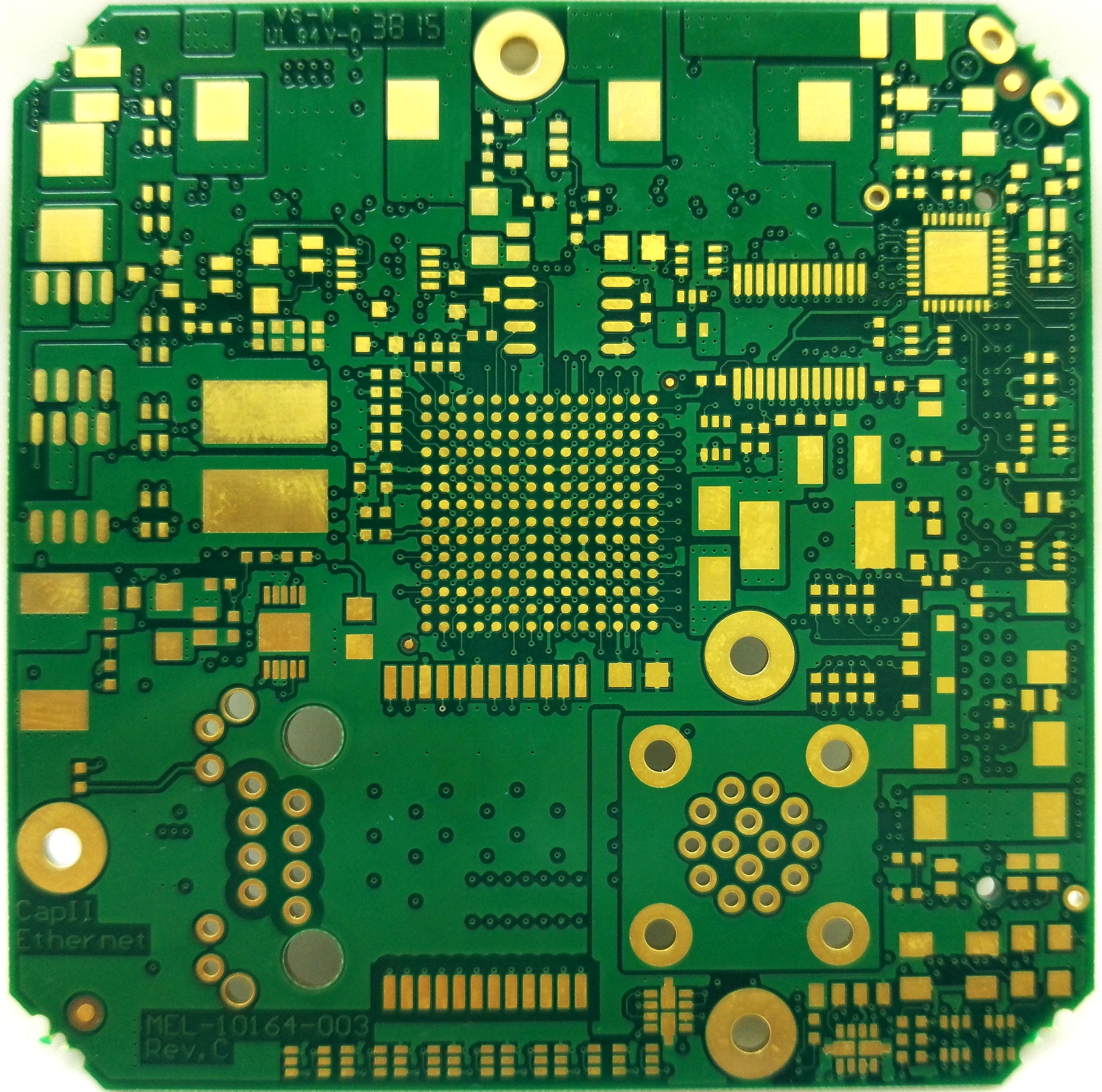

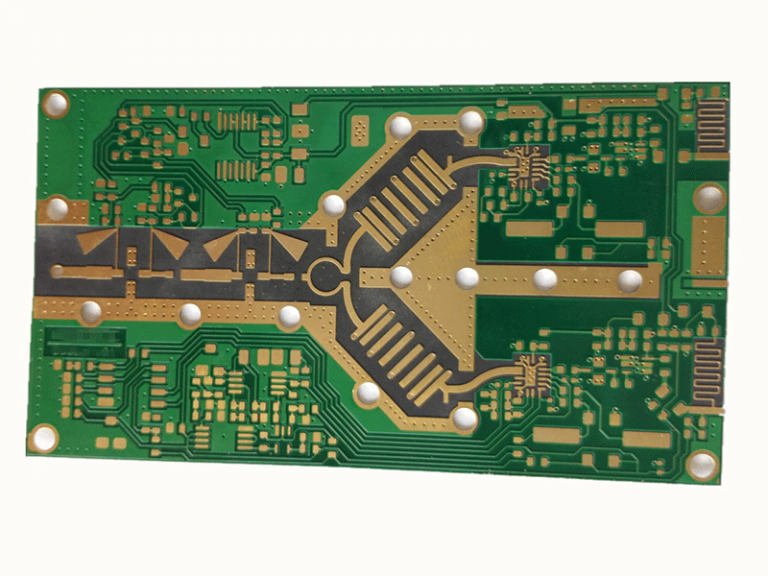

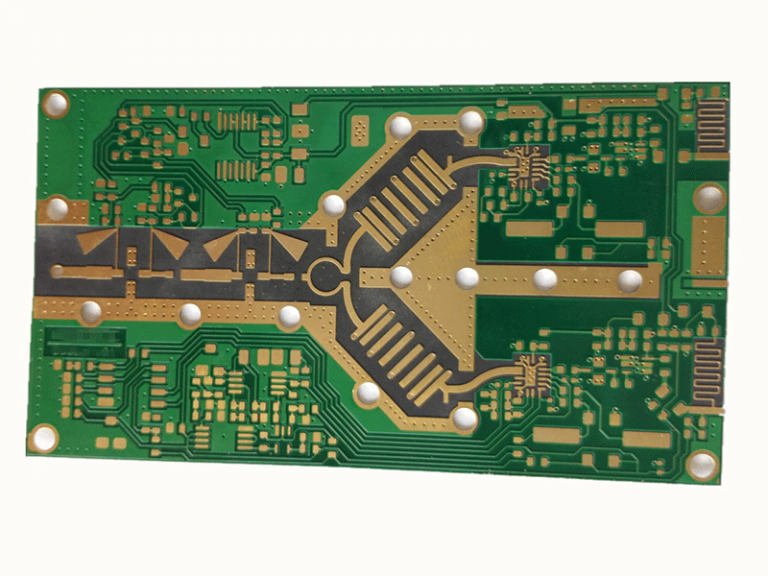

Introduction of various boards of high-frequency circuit board pcb

High frequency pcb refers to high frequency circuit board. High-frequency and induction heating technology currently has the highest heating efficiency and fastest speed for metal materials, and is low-consumption and environmentally friendly. It has been widely used in thermal processing, heat treatment, thermal assembly, welding, smelting and other processes of metal materials. It can not only heat the workpiece as a whole, but also heat the parts of the workpiece in a targeted manner; it can realize deep heat penetration of the workpiece, and can also only heat its surface and surface; it can not only directly heat metal materials, but also heat non-metallic materials. The material is heated indirectly. Therefore, induction heating technology will be more and more widely used in all walks of life, so high-frequency PCB production and material selection are particularly important.

The production of PCB high-frequency circuit boards requires that high-frequency circuit boards are one of the most difficult boards, so they must meet the production requirements as much as possible.

1. Drilling

1. Drilling speed should be slow to 180/S. New drill bit should be used, and aluminum sheets should be placed on the upper and lower sides. It is best to drill with single PNL, and the hole should not be exposed to water.

2. Concentrated sulfuric acid (preferably not used) for 30Min can be used for the PTH hole template

3. The sinking copper circuit of the grinding plate is made the same as the normal double-sided

4. Special attention: High frequency circuit board does not need to remove slag.

2. Solder mask

1. If the high-frequency circuit board needs to be printed with green oil on the base material, the green oil should be printed twice (to prevent the green oil from foaming on the base material), and the board should not be ground before etching and stripping, but can only be air-dried. For the first primer, use a 43T screen plate to print the segmented baking board normally: 50 degrees 50Min75 degrees 50Min95 degrees 50Min120 degrees 50Min135 degrees 50Min15050Min degrees, expose with line film, grind the board after developing, and make it normally for the second time. It needs to be noted in MI: the first primer is aligned with the line film.

2. If the high-frequency circuit board needs to be grounded with green oil, it is not allowed to grind the board before the solder mask, and the red stamp will be stamped in the MI.

3. If the high-frequency circuit board needs to print green oil on some substrates and not print green oil on some substrates, a "priming film" is required. The priming film only retains the green oil on the substrate, and then the second The second normal production.

3. Spray tin

Before spraying tin, it should be baked at 150 degrees for 30 minutes before spraying tin.

4. Line Tolerance

The unrequired line width tolerance is ±0.05mm, and the production is made according to customer requirements.

5. Plate

Introduction, divided into: 94HB, fireproof board (94VO, FR-1, FR-2), half glass fiber (22F, CEM-1, CEM-3), full glass fiber (FR-4).

FR-1: Features: 1. Halogen-free sheet, good for environmental protection 2. High tracking index (above 600 volts, special requirements are required) 3. Suitable punching temperature is 40-70°C 4. Bow curvature , small twist rate and stable

FR-2: Features: Excellent leakage resistance (above 600V) 5. Low cost and wide application range 6. Excellent moisture and heat resistance 7. Suitable punching temperature is 40-70°C 8. Bow curvature and twist rate Small and stable 9. Superior dimensional stability

CEM-3: Features: Excellent machinability, punchability 1. The electrical performance is equivalent to FR-4, the processing technology is the same as FR-4, the drill bit wear rate is smaller than FR-4 2. Multi-level leakage resistance Traceability (CTI 175V, CTI300V, CTI 600V) 3. Comply with the specification requirements of IPC-4101A

FR-4: Features: Halogen-free, bromine and chlorine content is less than 0.09% Halogen-free, Br/Cl content below 0.09% 1. Does not contain antimony and red phosphorus, no toxic components remain when burning Antimony and red phosphor free, Absence of highly toxic dioxins in burning exhaust gas 2. Harder than KB-6160

The following is the product model: Paper Copper Clad Panel

KB-3152FR-1

It is an environmentally friendly halogen-free and antimony-free paper-based phenolic resin copper laminate developed for environmental protection, which can avoid toxic substances and gases produced when burning boards containing halogen and antimony. Has a high leakage index (above 600 volts) and is suitable for low temperature punching operations.

KB-3151S FR-1

It is a paper-based phenolic resin copper area laminate developed to meet the needs of precision circuit boards such as high-density automatic plug-in and chip parts surface adhesion technology. Has excellent resistance to silver migration and electrical performance in wet environments.

KB-3150/KB-3151

It is a newly developed paper-based phenolic resin copper area laminate for the needs of precision circuit boards such as high-density automatic plug-in and chip component surface adhesion technology. Available with high leakage index (above 600 volts) and suitable for low temperature punching operations.

KB-3150FR-1

It is a paper-based phenolic resin insulation laminate developed for precision components such as switch face boxes (such as: key switches, push-type switches). It has excellent flame retardancy and dimensional stability, and is suitable for low-temperature punching operations.

KB-2151FR-2

It is a paper-based phenolic resin copper area laminate developed to meet the needs of precision circuit boards such as high-density automatic plug-in and chip component surface adhesion technology.

KB-2150G/2150GC FR-2

It is an environmentally friendly halogen-free and antimony-free paper-based phenolic resin copper laminate developed for environmental protection, which can avoid toxic substances and gases produced when burning boards containing halogen and antimony. It not only maintains the good performance of FR-2, but also has excellent moisture resistance and heat resistance.

KB-150/1150/150D Unclad (ANSI:XPC)

It is a paper-based phenolic resin insulation laminate developed to meet the needs of precision components for mechanical transmission. It has good moisture and heat resistance, and is suitable for low temperature punching processing operations.

KB-1150/KB-1151 ANSI XPC

It is a paper-based phenolic resin copper laminate with good moisture and heat resistance, and is suitable for low temperature punching processing operations.