PCB assembly manufacturing needs in the medical industry

As the aging population grows, the importance of PCB manufacturing in the medical industry will continue to grow. For example, PCBs play a vital role in medical imaging units such as MRIs and cardiac monitoring equipment such as pacemakers. Even body temperature monitoring devices and responsive neurostimulators can be implemented with state-of-the-art PCB technology and components. So today we will discuss the role of PCB in the medical industry.

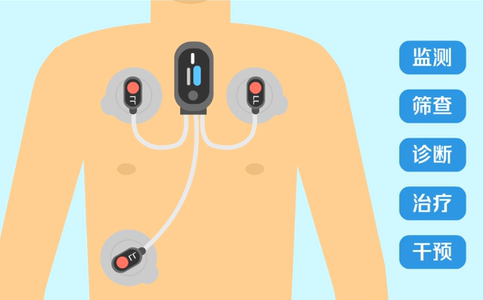

1. Wearable medical equipment that is easy to wear

Currently, the patient wearable medical device market is growing at a rate of more than 16% per year. Additionally, medical devices are becoming smaller, lighter, and easier to wear without compromising accuracy or durability. Many of these devices use in-line motion sensors to compile relevant data, which is then forwarded to the appropriate healthcare professional. The top medical devices on the market are already so powerful that some can even detect when a patient's wound is infected. The realization of these functions is the design innovation of the scientific researchers behind it and the technical support of the PCB manufacturing industry.

With the aging trend of my country's population becoming increasingly serious, elderly care will also become a domestic growth market, so wearable medical devices are not limited to the traditional medical industry, but will also become a major demand for home furnishing and elderly care as the aging population grows.

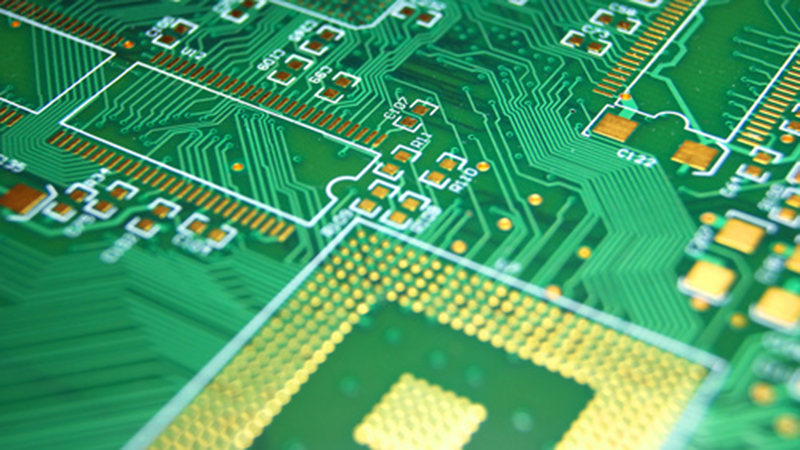

2. Implantable medical devices

The use of PCB assembly becomes even more complicated when it comes to implantable medical devices, as there is no uniform standard to which all PCB assemblies adhere. That said, different implants will achieve different goals for different medical conditions, and the unstable nature of implants can also affect PCB design and fabrication.

For example, relying on the manufacture of sophisticated PCB circuit boards, deaf people can hear sounds through cochlear implants. And those with advanced cardiovascular disease who could benefit from implanted defibrillators, among other things. Therefore, in this field, the PCB manufacturing industry still has higher efficiency to develop.

3. Heart rate health type medical devices

In the past, the integration of heart rate health record type devices was very poor, and many electronic devices lacked any kind of connection. Instead, each system is a direct system that handles orders, documents, and other tasks in its own way. Over time, these systems have been merged to form a more comprehensive interface, which also allows the pharmaceutical industry to enhance the medical care of patients and further improve efficiency.

4. Medical sterilization type equipment

At the end of 22, my country's epidemic prevention policy was officially released, which allowed many public places to reopen, and people returned to work after a long period of isolation and blockade. Therefore, it is a very important measure to disinfect and sterilize the environment where people live, not only in hospitals, but also in some large public places such as schools, subway stations, and offices. Increase the risk of people being exposed to the virus and becoming infected. The development and manufacture of sterilization equipment and systems can solve these problems well. The advanced disinfection robot can perform multiple disinfections for 24 hours, purify the air, improve work efficiency in an all-round way, and at the same time strengthen the epidemic prevention measures in public places.

5. Mobile medical facilities

With the advancement of PCB assembly technology, traditional wires and flexible wires have quickly become a thing of the past. In the past, traditional electrical outlets were often used for plugging and unplugging cords and cords, but modern medical innovations allow doctors to care for patients anytime, anywhere.

In fact, the mHealth market was estimated to be worth more than $20 billion as early as the year before last, with smartphones, iPads and other such devices enabling healthcare providers to easily receive and transmit vital medical information as needed. Thanks to advances in mobile medicine, you can better help patients by filling out documents, ordering equipment and medications, and researching certain symptoms or conditions with just a few mouse clicks.

There is a close and indispensable relationship between medical care and PCB manufacturing industry. Key medical instruments and equipment are inseparable from PCB manufacturing technology and design solutions. The high-quality standards observed by the medical market also promote the technological development of the PCB manufacturing industry. Nanjing Yunheng PCBA One-stop service provider, has been engaged in PCBA assembly, component procurement and other fields for a long time, and its products serve various fields such as medical care, transportation, industrial control, consumer electronics, etc., providing high-standard and high-quality hardware manufacturing and processing for global smart hardware companies Serve!