With the rapid development of the electronic industry, the demand for pcb circuit boardsis also increasing. The competition in the pcb circuit board industry is fierce, and the prices set by different manufacturers on the market are not the same. It is difficult for consumers to judge whether the prices set by manufacturers are reasonable. In this regard, Jing Bang technicians for everyone to analyze the answer:

Factors affecting the price of pcb circuit boards:

1. Different materials are used

Take the common double panel for example, the board is generally FR-4, CEM-3, etc. The board thickness varies from 0.2mm to 5.0mm, and the copper thickness varies from 0.05Oz to 3Oz, which also causes the price difference. In welding ink, ordinary thermosetting oil and photosensitive green oil also have a certain price difference.

2. Different production processes

pcb circuit board has a variety of production processes, such as gold-plated plate and tin plate, the production of shape gong (milling) board and beer (punching) board, the use of silk screen line and dry film line, different production process costs are not the same.

3. pcb difficulty is different

pcb circuit board itself is also difficult to divide, the more difficult the cost is greater. If there are 1000 holes on both types of circuit boards, the hole diameter of one board is greater than 0.6mm and that of the other board is less than 0.6mm, different drilling costs will be formed; If the other two kinds of circuit boards are the same, but the line width and line distance are different, one is greater than 0.2mm, one is less than 0.2mm, it will also cause different production costs, because the difficult board scrap rate is higher, so the cost is high.

4. Different customer requirements

As each customer has different requirements for pcb boards, the production cost is also different. The level of customer requirements will directly affect the finished product rate of the board factory, for example, a board according to IPC-A-600E, 98% qualified rate, but according to the requirements of class3 may only 90% qualified rate.

5. Different manufacturers

pcb circuit board manufacturers are not the same in production equipment, process, technology and other aspects, so even if it is the same product, it will form different costs. For example, some manufacturers in order to reduce costs and speed up production, will produce low cost, simple process of tin spray plate, and some manufacturers are producing gold-plated plate, scrap that rise, resulting in higher costs.

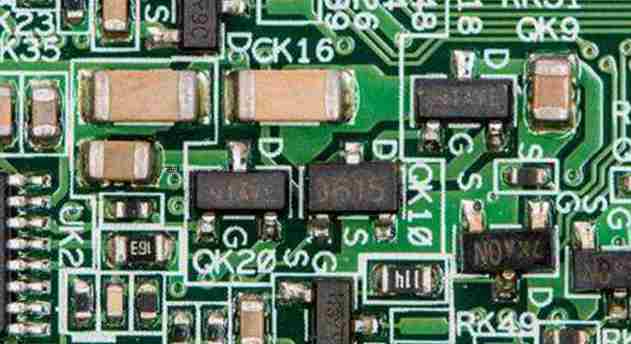

Seoul Semiconductor introduces the latest patent Acrich module for full Angle bulb lamp

Seoul Semiconductor, one of the world's leading LED manufacturers, announced on July 29 that it has officially launched Acrich MJT2525 module for bulb lights. The Acrich MJT2525 module uses an innovative reflector, combined with Seoul Semiconductor's strong patent strength, to achieve the full Angle bulb light required by Energy Star. Energy Star is a program that certifies electrical and electronic products for energy efficiency in order to reduce greenhouse gas emissions. It is a representative symbol of energy efficiency.

Comparison of the luminous direction of traditional LED bulb lamp and Acrich module full-angle bulb bulb lamp

The Acrich MJT2525 module maximizes the benefits of Acrich MJT2525 leds to provide the best full-angle bulb bulb lighting solution. The Acirch MJT2525 used on the module uses dome-shaped lenses, which are difficult to use on ultra-small leds, to enlarge the luminous Angle to 130 degrees, thus increasing the luminous area of a single LED. The Acrich MJT2525 module uses 2.5mm X 2.5mm compact high lumen density LED. All components required for the module can be integrated on a 38mm diameter PCB board. Based on such small PCB board and innovative reflectors, the optimal luminous solution is designed. This design will not only reduce the visual difference from using traditional semi-circular LED lights, but also continue to maintain the feeling that consumers have been using incandescent bulbs for more than 100 years. In addition, due to the use of Acrich3 technology, greatly improved dimming function.

Acrich MJT 2525 module for bulb lamp

Jay Kim, head of the lighting division at Seoul Semiconductor, said bulb bulbs are typical of the alternative lighting market and cost-effectiveness is very important. The Acrich MJT2525 module is very cost effective by optimizing heat resistance design, reducing heat sink size and minimising PCB size with ultra-small leds. We expect Acrich MJT2525 to receive a warm response in the lighting market.