As we all know, the Pearl River Delta, especially Guangzhou, Shenzhen and other places have the largest number of electronic manufacturers. However, besides these places, there are also other places, such as the Yangtze River Delta, Bohai Rim and the mainland, where there are high-quality smt manufacturers. Therefore, to find high-quality manufacturers, we must follow the following points: The following patch processing manufacturers Xiaobian to explain how to choose high quality patch processing manufacturers and how to reduce the relevant knowledge of PCBA circuit board tin beads.

1. How to reduce the PCBA circuit board tin beads

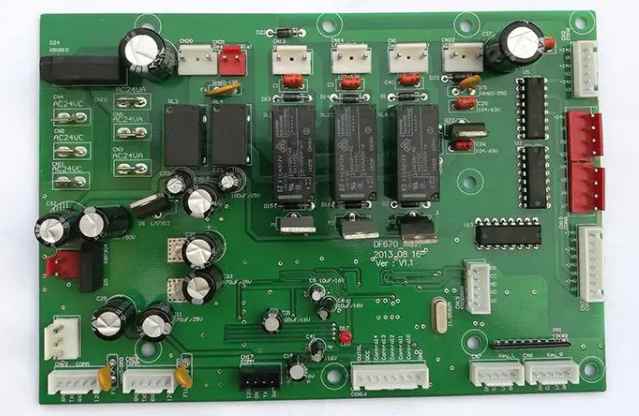

In the process of PCBA processing, due to the factors of technology and manual work, it is inevitable that occasional tin beads and tin residue will remain on the PCBA board, which causes great hidden trouble for the use of products. Because tin beads and tin residue will loosen in uncertain environment, forming short circuit of PCBA board and resulting in product failure. The point is that this probability is likely to occur in the life cycle of the product, causing great pressure on the customer after sale.

The root cause of tin residue of PCBA tin beads

1. The amount of tin on the SMD pad is too much. In the reflow welding process, the molten tin extrudes thPCB boarde corresponding tin beads

2, or components are damp, moisture in reflow welding burst, splashing tin beads scattered to the surface

3, DIP plug-in after welding operation, manual adding tin tin, iron head splashing tin beads scattered to the PCBA board surface

4. Other unknown reasons

Measures to reduce the tin residue of PCBA tin beads

1. Attach importance to the production of steel mesh. It is necessary to adjust the opening size appropriately according to the specific component layout of PCBA board, so as to control the printing amount of solder paste. Especially for some dense foot components or panel components are more dense.

2. PCB bare board with BGA, QFN and close foot components is recommended to adopt strict baking action to ensure the removal of water on the surface of the pad, maximize the solderability and eliminate the production of tin beads

3. PCBA processing manufacturers will inevitably introduce hand welder position, which requires strict control of tin dumping operation on management.

Arrange a special storage box, clean the table in time, and strengthen the post-welding pull QC for visual inspection of the SMD components around the hand-welded components, focusing on whether the SMD component solder spot was accidentally dissolved by touch or the tin bead tin slag scattered between the component pins. PCBA board is a relatively precise product component, which is very sensitive to conductive objects and ESD static electricity. In the process of PCBA, factory managers need to improve the management level (IPC-A-610E Class II is recommended at least), strengthen the quality awareness of operators and quality teams, and carry out implementation from two aspects of process control and ideological consciousness, so as to avoid the generation of tin beads and tin slag on PCBA board surface to the greatest extent.

2. How to choose high quality patch manufacturer

Because there are so many smt manufacturers, enterprise customers will always be troubled when choosing. For this situation, today Xiaobian has made a survey summary, and the following will be shared with you, hoping to help friends who want to know where the high-quality smt manufacturers have them. As we all know, the Pearl River Delta, especially Guangzhou, Shenzhen and other places have the largest number of electronic manufacturers. However, besides these places, there are also other places, such as the Yangtze River Delta, Bohai Rim and the mainland, where there are high-quality smt manufacturers. Therefore, in order to find high-quality manufacturers, we must follow the following points:

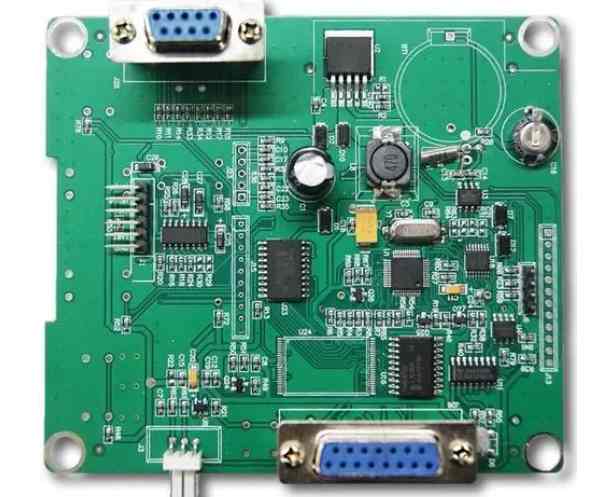

First, it does not matter whether the scale is large or not. Before the key fit or not, many people have misunderstandings about the choice of high-quality smt manufacturers, believing that as long as the scale is large, it must be good. This does have a great reference value, but it is not absolute, and large-scale SMT manufacturers may not be suitable for all corporate customers. On the one hand, some enterprise customers need to make small-batch sample orders, which do not need to find large-scale manufacturers. On the other hand, large-scale smt manufacturers often charge high fees, and the order quantity is large and the queuing time is long. Therefore, instead of this, it is better to directly choose suitable for their own enterprise production of smt manufacturers. Although the scale of these manufacturers is not as large as the processing plant, but they each have their own advantages, each has their own strengths, and their good fields are targeted, suitable for specific production enterprises.

Two, excellent is not excellent, see the equipment quality smt manufacturers are generally divided into two kinds, one is to take the high-end precision route, the other is to take the low-end cheap route. The former is often large-scale, large input processing plant, the latter is more in small workshops, individual entrepreneurship, only the machine, not many employees, equipment is relatively old do not say, there is no warehouse pipe, more no quality assurance, only boot and play two kinds of operation, very simple, the price is also very cheap. Of course, the quality of such a small workshop is difficult to guarantee, if it is a high precision added value of the board, must not choose this, otherwise it will regret.

Three, choose not to choose to look at professional cooperation as an important part of electronic products, smt manufacturer's professional cooperation determines whether the circuit board can be delivered as scheduled, how much repair rate and how much product quality rate. Therefore, if you want to find high-quality smt manufacturers, you must find a high degree of professional cooperation. So, how to judge the degree of professional cooperation? We can observe the attitude and philosophy of SMT manufacturers by talking with their management, bosses and employees, learn about their market reputation SMT processing through the third party, and learn about their services through the customers we have served.

Four, quality management in addition to the above three points, there is another important point is to judge whether the manufacturer is excellent basis, namely, quality management. At present, in order to attract customers, someplants will attract customers' attention and sign orders with low prices. However, in order to ensure their own profits, they will find a balance from other aspects, such as reducing QC personnel, not equipped with AOI and other detection means, which will lead to the quality of circuit boards will be reduced. Therefore, when choosing high-quality smt manufacturers, we must pay attention to the fact that only comprehensive understanding can ensure the perfect processing of products, improve the performance and service life of products, and gain favorable market.