At present, the demand for PCB circuit boards is increasing, the market demand is also increasing, circuit board manufacturers emerge in endlessly. For buyers, there are more choices. But from this point on, how to choose a high quality pcb patch proofing manufacturer, has become a headache for many electronic manufacturers. The following patch processing manufacturer to explain how to ensure the quality of the patch and pcb how to choose fast all the patch knowledge.

1. How to select fast all-patch pcb

1. There are many kinds of PCB circuit boards, which need various high-end technical support and research and development in the process of PCB proofing production. In order to know whether the products produced by the manufacturer meet our procurement requirements, you can first ask the manufacturer to provide some PCB samples, and then judge the strength and professionalism of the manufacturer by the quality of these samples.

2.PCB circuit board is currently used in all walks of life, a high-quality circuit board manufacturer, the production of circuit board products should not be single, should be able to provide different products for different industry needs.

3. Listen to the customer's voice feedback, will more truly reflect the strength of the manufacturer, service and other aspects. Therefore, before deciding whether to choose this pcb patch proofing manufacturer, it is best to search the information of related enterprises on the Internet to see if there is bad negative information. If there is, please choose carefully.

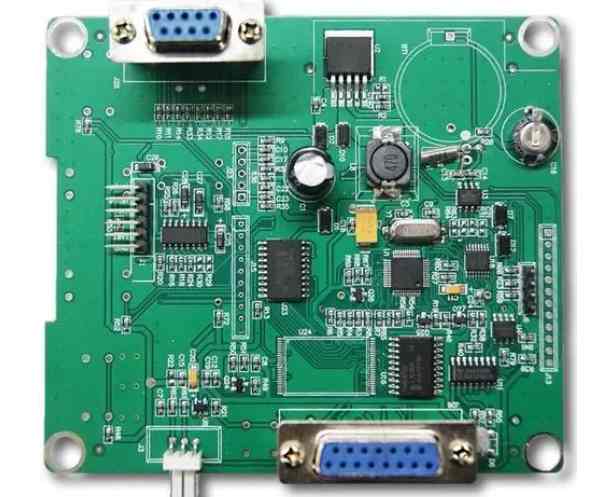

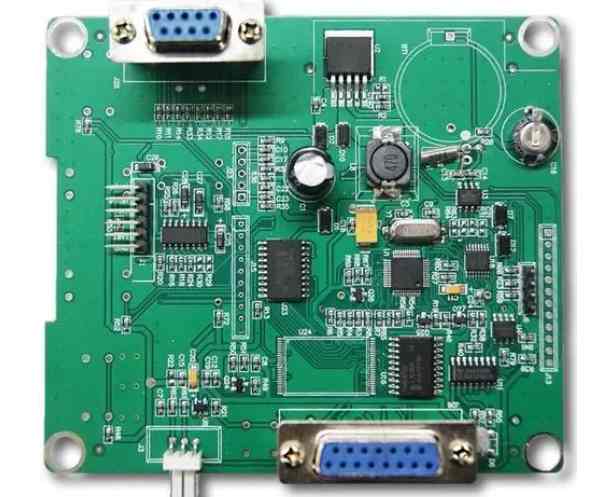

4. It can be observed from the appearance of the product, mainly from the thickness, specification and size of the product and the color of the external circuit board of the product. If the color is bright and the ink is covered, the quality of PCB proofing products is very good. In addition, we should also pay attention to the details, such as whether the quality of the welding process of the product is perfect, because this directly affects the use of PCB products.

5. According to the test results of the products, when selecting PCB patch proofing products, the manufacturer should be allowed to conduct quality testing on the products, such as checking whether there is heating, circuit breaking, short circuit and so on in the circuit, and observing whether the products can run stably in high temperature and other environments. If the test results have no obvious defects, the quality will be better.

6. From the perspective of comprehensive factors, the reputation of PCB manufacturers can be reflected in the business license, certificate of honor, cooperative customers and other aspects. In addition, it is also possible to know whether the manufacturer has a good reputation, which can be said to be done through the manufacturer's commitment to the customer.

7. Good pcb patch proofing manufacturers certainly need good service. pcb patch proofing involves many problems such as product process, product use, product warranty and so on, which requires a perfect service system.

The pre-sale service can be seen through the communication with the manufacturer, whether it can give customers a detailed product introduction, whether it can patiently and quickly solve customer problems. After-sales service depends on whether the manufacturer can provide solutions for possible problems in the later period, such as packaging replacement, warranty, technical guidance, etc.

2. How to ensure the quality of the patch

To ensure the quality of SMT patch processing, the following conditions must be met:

1. Rigorous SOP production process control, responsible for SMT patch, DIP welding and back-end assembly testing.

2. Professional technical team (engineer/technician working in smt industry for more than 10 years)

3. Complete incoming material inspection and confirmation process, check PCB and materials

4. PCBA new machine type production project team, responsible for quality control of the first production of new customers.

5. Strict confirmation process for the first piece, final confirmation of the version with the customer based on PCB drawings, PCBA samples, etc.

6. SMT patch processing and production process control: solder paste viscosity testing, solder paste printing thickness testing, patch accuracy testing, pre-furnace mounting testing, post-furnace spot testing, post-furnace AOI full inspection, finished product testing.

7. SMT auxiliary materials can be used with thousand/Alpha solder paste to ensure the welding quality and stability of the patch.

8. The equipment adopts high precision SMT machine, the minimum patch is 03015, to ensure the SMT accuracy and efficiency

9. German REHM13 hot zone reflow welding is selected to ensure the quality of reflow stage and cope with various types of PCBA products

10. Nitrogen technology and device storage, responding to pcba customers with high requirements and high precision

11.SMT workshop environment monitoring: 25 plus or minus 2 degrees, relative humidity: 40%-60%.