Before SMT patch production, it is necessary to understand how to use SMT solder paste. So, in the end how to use SMT solder paste? Let's find out. How to use the solder paste of SMT patch? Wipe the solder spot clean first. Pay attention to wipe it very clean and do not have any residue, otherwise it will affect the following work. The following patch processing manufacturer Xiaobian to explain how to use SMT patch processing solder paste and patch processing manufacturers how to improve the efficiency of the relevant knowledge.

1. How do patch manufacturers improve efficiency

As we all know, SMT patch processing is a very important electronic engineering technology, but also reflects a regional manufacturing process capacity of the industry, leaders, experts, capital are constantly optimizing and improving technology and management methods to improve the processing efficiency. If the number of customers and order quantity of the enterprise is relatively fixed, the total production is relatively stable, at this time in order to improve the production speed can increase the production line, of course, the cost will rise.

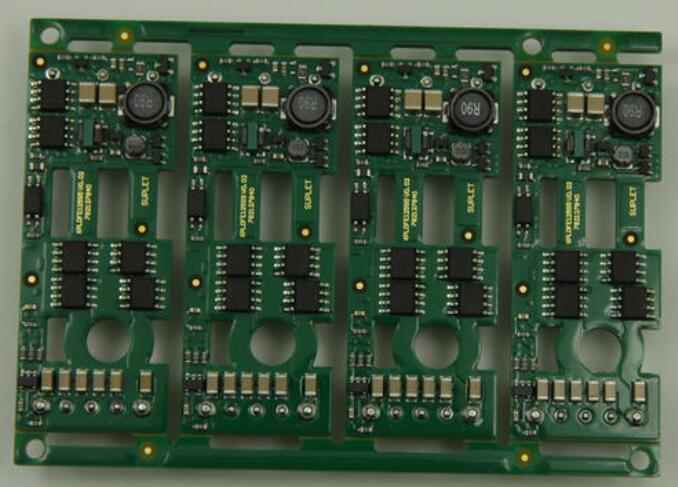

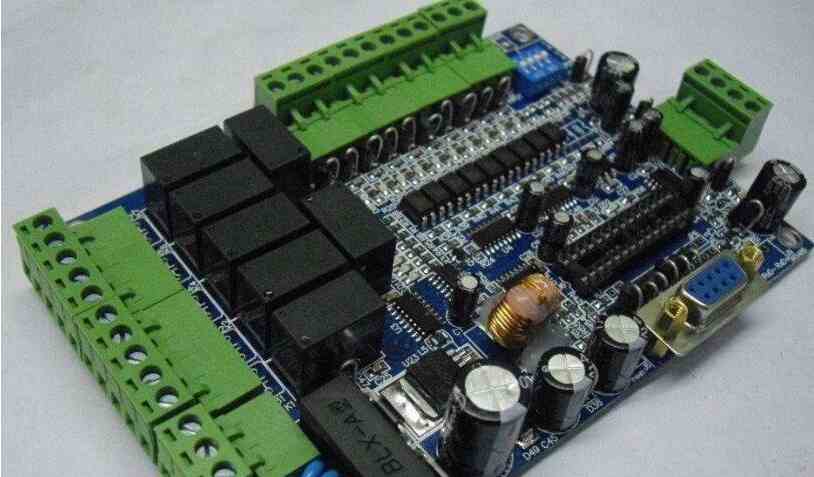

We know that the production line is mainly composed of silk screen printing machine, high-speed SMT machine, multifunctional SMT machine, reflow welding machine and AOI automatic detector. If multiple SMT machines cooperate with each other to complete a mounting process, that is, when there is a significant gap in the mounting time, the overall SMT rate will be seriously affected. So if the total amount of engineering remains the same, no additional production lines, through technical means and management methods to improve the efficiency of the patch, how to do?

According to the order and production, the number of components should be reasonably allocated to achieve load balancing, so that the patch time in multiple production lines is equal or similar. This one is particularly well done in large patch processing manufacturers, which can be said to be the work of details. It is also the most obvious point that the efficiency of large factories is much higher than that of small and medium-sized factories. Many small factories are not managed in place, some machines are loaded very high, and some machines are relatively idle.

Two, extreme overclocking this term first began from the computer core CPU, some enthusiasts through certain technical means desperately load its frequency, without affecting its service life and working quality, maximize the performance of the hardware. We know that there is a maximum speed of the SMT machine, but it is limited by the machine structure. It is difficult to approach this value in ordinary ways. If certain technical measures such as making the mounting head grab the components at the same time and try to arrange the same type of components together, there is no need to frequently switch the mounting head when picking up the components next time, which can greatly reduce the waste of time.

3. Assembly line operation No matter in large or small factories, there are more equipment in the production line, and they are closely coordinated with each other and have rigorous working procedures. If any link has problems or speed delay, it will directly affect the following working procedures in series, thus slowing down the whole processing process. In order to avoid this problem, change this state, in addition to the theoretical training of workers, but also need to practice training, master on-site practice guidance operation, so that workers have rich experience in order to complete the process work. Large patch manufacturers have a very rigorous process and work discipline, but also a lot of training, guidance and expert learning, this is a scientific reason.

2. How to use solder paste for SMT patch processing

In the process of patch production, one of the most important links is adding solder paste. Only when the solder paste is OK, can we ensure that the subsequent production will not easily cause big problems. Therefore, before SMT patch production, we must first understand how to use SMT solder paste. So, in the end how to use SMT solder paste? Let's find out. How to use the solder paste of SMT patch? Wipe the solder spot clean first. Pay attention to wipe it very clean and do not have any residue, otherwise it will affect the following work. Then, apply a little solder paste on it, and then eat with a soldering iron. Press the wire or pin line on the welding point with tweezers, press gently with the tip to ensure that there is enough tin flow to the welding point, quickly remove it, the process should be fast. Once the paste has cooled, you can release the tweezers and proceed to the next step. Note, when adding solder paste, we must ensure that the steel mesh is clean, the amount of solder paste on the steel mesh cannot exceed one centimeter, and we should always ensure that the spade and container are clean and easy to operate. In fact, the operation of SMT solder paste is very simple, but there is a very important process that needs to be completed before adding solder paste, and many manufacturers may have problems if they do not pay attention to it, so, what is the problem? According to industry insiders, before adding solder paste, the first thing to do is to preserve the paste. Only by mastering the correct preservation method of solder paste, can we extend its life and give full play to its maximum function.

1, the solder paste must be stored in the refrigerator, the temperature is controlled between 2 degrees and 10 degrees, unopened solder paste can be placed for about six months, after the opening of the solder paste only 24 hours of life, to be used up in this time, otherwise the solder paste will lose effect.

2. Remind you that you must not put the solder paste in the place where the solar energy irradiates, so as not to change the solder paste.

3. Before using the solder paste, it must be returned to temperature, that is, put the solder paste at room temperature, so that it can be restored to the natural room temperature. The purpose of return temperature has two, one is not to directly use the solder paste from the refrigerator, the other is the hot air outside contact with the cold temperature of the solder paste, will condensing into beads, at this time open use is easy to produce tin beads, and, at low temperature of the solder paste, adhesion is very low, can not meet the requirements of the manufacturer printing, so, must be used after the return temperature.

4. It should be noted that the shorter the opening time of the solder paste, the better. In the process of use, do not take all of it out, and cover the rest with the inner cover and put it back in the refrigerator. Of course, do not use how much to take how much, roughly estimate the amount required for production, and then take the appropriate amount, so as to avoid frequent contact with the tin paste and air, reduce oxidation. After covering the inner cover, cover the outer cover to ensure that the remaining solder paste does not come into contact with the air. How to use SMT solder paste? When the job is finished and there is solder paste left, be sure to put it in the empty bottle, do not put back the original bottle. In addition, it should be isolated from the air to avoid oxidation.