Due to the regional market, in order to meet the needs of products, electronic technology companies have spawned a large number of SMT patch OEM factories, which are known to us as electronics factories. Among the numerous SMT factories, how to choose a reliable supplier? This article from the perspective of industry professionals suggested from the following aspects of screening, to ensure that your choice of minimum cost, conducive to long-term cooperation. The following PCBA processing manufacturer to explain how to inspect SMT patch processing plant and SMT patch processing how to quickly ship the relevant knowledge.

1. How to deliver SMT patch processing quickly

I. SMT patch processing data (patch BOM, patch position coordinates, patch drawing, sample, etc.) shall be prepared in advance and sent to the factory, and the off-line procedures of the patch shall be prepared in advance.

2. SMD materials provided must be accurate (quantity of incoming materials, material specifications and parameters).

Three, the following several common problems must be marked on the BOM, do not ask you to confirm the production

1. Because SMT plant has two shifts, it is impossible to call you at midnight for confirmation during night shift production.

2. If it is confirmed that the incoming material is wrong and the machine cannot be loaded, the board can only be put aside and pasted with other types of machine.

4. Incoming resistance must explain the precision of components (1% or 5%)

5. Incoming capacitor class must indicate the voltage number of components

6.IC chip two triode class, if it can be used, also note on the BOM.

2. How to inspect SMT patch factory

Shenzhen, the world famous electronic city. The convergence of technology and electronics companies from all over the world has made Shenzhen a world-class electronics market. Because of this regional market, electronic technology companies in order to meet the needs of products, spawned a large number of SMT patch OEM factories, which are known to us as electronics factories. Among the numerous SMT factories, how to choose a reliable supplier? This article from the perspective of industry professionals suggested from the following aspects of screening, to ensure that your choice of minimum cost, conducive to long-term cooperation. There are so many large and small processing plants in Shenzhen that we do not know which phone to call. When we call to inquire, we can get the most information about the SMT OEM factory: Personnel, equipment, site size, equipment origin, poor understanding after the field visit to Shenzhen processing plant more, more to you do not know who size, which is true or false, simply ask equipment and personnel is not necessarily, the size of the general small workshop, more than ten or twenty people, a few people. Speaking of inspection, this kind of processing workshop we can avoid talking about. General investigation before the contact will come out of a quotation, the price of each company is the same. If the quotation is slightly out of line, one SMT factory will be denied. It is possible to deny a very good factory. Those who dare to speak, are capable of quality requirements, the initial offer can only refer to, or even do not refer to.

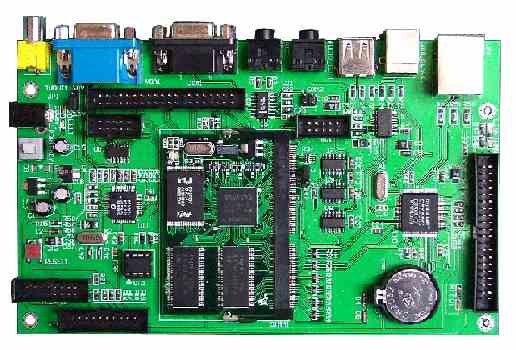

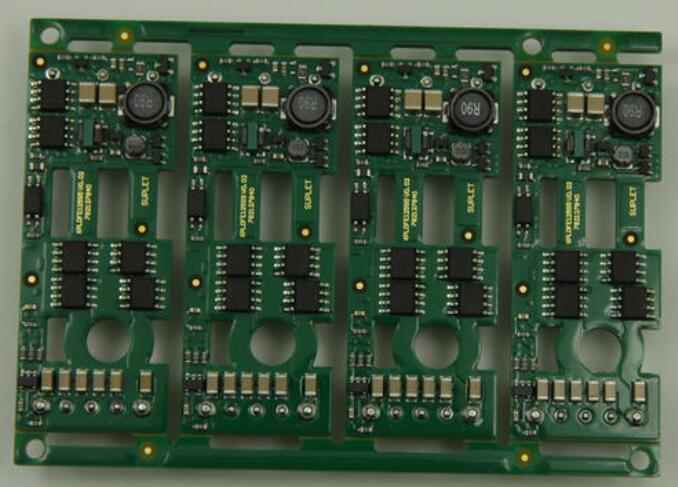

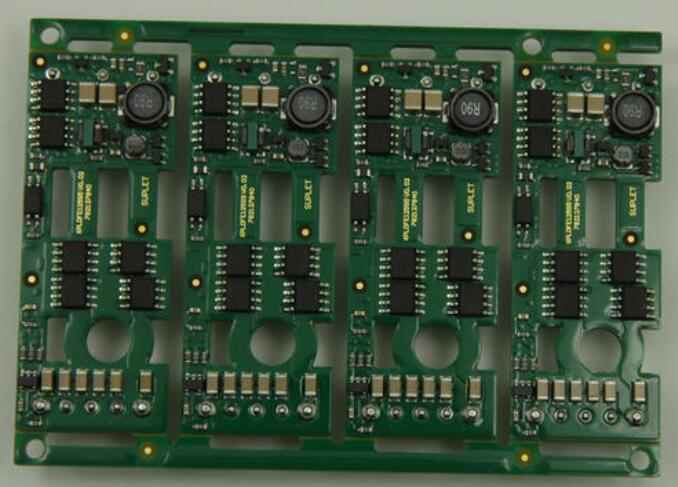

General regular manufacturers, unless your order is large enough, or any SMT processing plant can come out. There is also SMT equipment: unless PCB board has very precise materials (such as 0201 and below) or very complex process, general factory SMT equipment can be done. Quality management process: In order to survive in the market, many SMT factories reduce prices time and time again, at the risk of sacrificing quality, reducing personnel and QC personnel, or not equipped with appropriate testing equipment (AOI) for testing and other means. In the process of evaluating SMT processing plant, it is necessary to observe and understand in detail whether IQC, post-furnace inspection, QC and other series positions are set up in the warehouse, whether AOI inspection equipment is reasonably equipped, whether it is opened and used, whether it is full inspection, and how engineers introduce and document quality management methods. In order to ensure that your products in this factory can get long-term quality assurance processing. (After reading my last article "Do you dare to do SMT patch processing for OEM factories that can't do these things", you will understand the importance of these positions.) Professional cooperation: SMT processing is a detail in every link of the entire electronic product manufacturing process. With highly developed equipment and perfect management, the professional cooperation and management level of SMT processing plant seem to determine whether your PCBA can be delivered on time, whether the quality can be controlled for a long time, and whether it can be repaired in time. The added value is much higher than the difference between a few cents and a few cents.

The inspection of the cooperation degree of SMT processing plant starts from the people: observe the morale of the staff, ask the details of the work of the grass-roots staff, and observe whether they have a sincere attitude and belief by talking with the management and even the boss of SMT processing plant. In addition, the third party can also know the reputation of the processing plant and the customer cases served and so on. The mental outlook of management and employees: the mental outlook of front-line employees and managers is a kind of morale. Whether employees and management can work hard and focus on energy determines whether your products can maintain a high straight through rate and consistency, because the products are made by people or operating equipment. Whether the communication with the manager is smooth, whether there is passion, whether the staff work meticulously, each does his job. An electronic technology company that can be promoted step by step must have SMT OEM factories with long-term stable quality assurance and other suppliers. However, a poor company will always be on the way to find a good SMT processing plant and repeat yesterday's story. With quality demands everywhere, it's time to rethink your purchasing mindset. Grasp the above several methods to select SMT factory, can be in the choice of suppliers without disadvantage