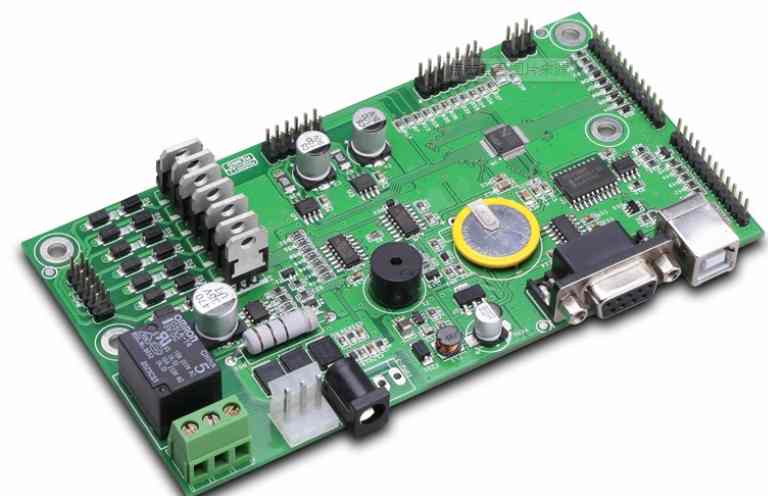

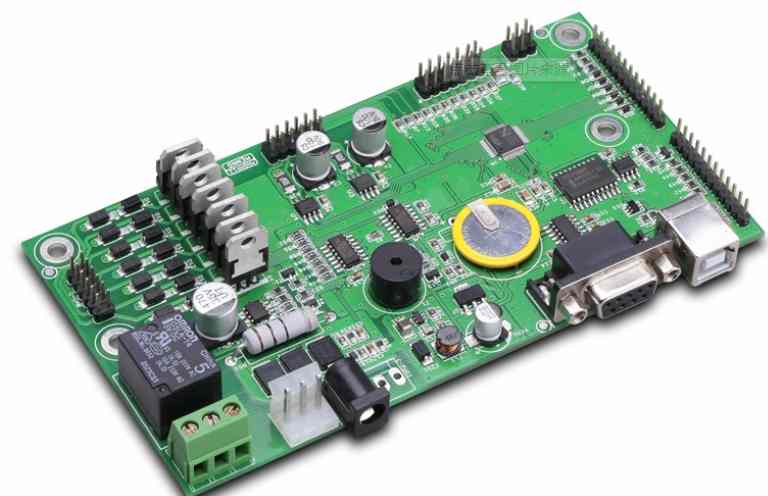

Circuit board as a high-end electronic industry essential products, its role in electronic products plays a pivotal role, so for the circuit board daily maintenance tools is more important, because once the circuit board appears any problem will lead to the circuit board can not work efficiently, the circuit board in the long-term operation process, it is difficult to avoid not infected with dust, So what should we do with the dust on the circuit board? The following to explain the circuit board how to dust and SMT plant should be how to choose the relevant knowledge.

1. How to choose SMT patch factory

With the rapid development of Shenzhen's electronic products industry, SMT SMT processing plants have gradually increased. How to choose the right SMT processing plant has become a top priority for every customer with this demand. Do you also have the same doubts? I would like to say that even if there are many SMT patch processing plants, the processing type is different, the difference is also very big. Just like a clothing store, each store has its own target customer. However, the company that needs processing may not understand it sometimes and think that as long as it is a patch factory, it can make other patches. From contact SMT patch processing to now 14 years, I have a deep understanding.

Most of the processing plants are SMT processing, rarely write some other words, such as BGA planting ball, write in this way, some people will understand, you can only plant the ball, do not do good processing, if so, there are no customers to come to the door, so, for the processing plant, to run more, find more, according to the number of their own products, and research and development production stage, to find their own more suitable processing plant. SMT processing plants in the Shenzhen market can be roughly divided into the following types: One is a customized processing plant, which belongs to the professional type and only produces for a certain industry or a certain product.

For example: only do mobile phone board, only do tablet, only stick red glue board, only protect the board, only stick LED lights or LED display and so on. All of their machines, auxiliary equipment, personnel, testing tools, are based on this kind of product. Although only do one kind of product, but external also called incoming material processing, if your product is not the kind they produce, I suggest you can look at other homes. One is the model processing plant, which belongs to the relatively large kind, the machine production line is more, the capacity is high. Dingchang is a high-end company in Shenzhen. Each line is equipped with automatic plate feeding machine, automatic printing machine, two high-precision modular machine and one high-precision multifunctional SMT machine. There are altogether four new automatic production lines. Each line is equipped with AOI optical detector, can produce mobile phones, tablets, TVS, Bluetooth and other high-end consumer electronic products; Electronic accessories are used in Japan thousands of columns, than the cost of the general factory up to 4 times above; The staff configuration is also very sound, four lines of SMT patch line and two plug-in lines are configured with more than 140 employees, the division of labor is very detailed: personnel, merchandising, planning, warehouse, BOM finishing technician, procurement, IPQC, QC, engineers divided into equipment engineers and electronic engineers, operators, operators, the cost of such configuration is naturally much higher than the general factory.

One is low-end cheap type, literally can understand. Used are second-hand high speed machine and medium speed SMT machine, personnel configuration can be saved, electronic accessories can be used at a low price. If your product is simple and high volume, look for the lower end so that the price is naturally lower. On the other hand, if you have a PCB board with high added value, complex boards, high precision, you have to look around and find that precision quality type. And then there's the workshop factory, with one or two machines and no people. The price is very low. Some only have high-speed machines, the factory has no warehouse pipe, no quality, only boot and play board, the price is very cheap, but the quality is difficult to guarantee! SMT processing plants have many, but professional do little. Can fully automatic paste, precision, quality, can substitute materials, can buy materials of this type of processing plants are few. With the rise of intelligent belt wearing and the Internet of Things, the research and development, production and small batch in the early stage need a batch of processing plants that can engage in lean production and fine processing.

2. How to remove dust from the circuit board

Method 1: Blow division Method:

This method is relatively good to remove the dust on the circuit board. The specific operation is that we need to use some inert gas to remove the dust of the circuit board. Generally, this gas is nitrogen, which is contained in large quantities in the air, so its price is relatively cheap. This dust removal nitrogen is free from oil and water. Of course, if economic conditions are not so good, regular nitrogen is fine. We choose to compress more clean space, hair dryer can also be, these methods are more money saving method, but the effect is still good!

Method 2: Electrodivision

The relative price of this method is expensive. First of all, we need to buy an electric dust device. The working principle of the electric dust device is: After the positive and negative of the electric dust collector is energized, the electric field is formed. With the continuous rise of the voltage, the magnetic field of the positive and negative two levels also becomes very large. When the intensity of the electromagnetic field reaches a certain degree, it will cause positive and negative discharge and cause corona, ionizing the air between the two levels into positive and negative ions, and the positive and negative electrons in the air will absorb dust. So as to achieve the effect of dust removal.