SMT production placement machine classification and process

SMT production placement machine classification

At present, there are many SMT manufacturers in the United States, and their structures are also different. However, they can be roughly divided into large scale high speed machines (commonly known as "high end machines") and medium sized medium speed machines (commonly known as "mid range machines") according to their scale and speed There are also small mounters and semi-automatic mounters/manual mounters Mainframe computers are usually three to four times more expensive than medium-sized computers Large high-speed patch machine manufacturers mainly include Panasonic, ASM, Fuji, Yamaha, Zhuji, Anbion, etc; Medium speed patch mechanism manufacturers mainly include Han Hua, Future, Data Manager, etc Among them, Panasonic, Hanhua, Yamaha and Fuji have the highest market share, and they are known as the "horsemanship" of the SMT market

SMT production placement machine classification

Whether it is a large machine manufacturer or a medium-sized machine manufacturer, the recommended SMT production line usually consists of two mounters: a chip mounter (usually called a high-speed mounter) and an IC component mounter (usually called a high-precision mounter). Each mounter takes its own responsibility, which helps to achieve the highest placement efficiency of the mounter. But now things are changing. Since many suppliers have introduced multi-functional mounters, SMT production line may only have one mounter. The multifunctional placement machine can complete the placement of all components, while maintaining a high placement speed and reducing investment. This placement machine is favored by small and medium-sized enterprises and scientific research institutes.

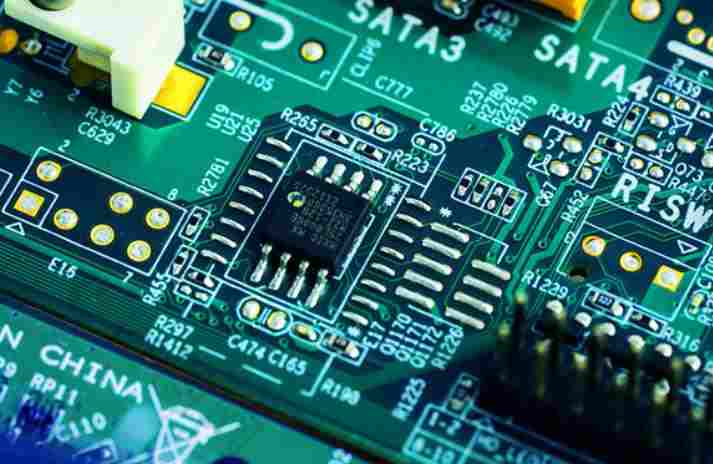

Circuit board

At present, the structure of the placement machine can be roughly divided into four types: boom type (also known as "arch type"), composite type, rotary table type and large parallel system.

The boom mounter is the most traditional mounter, which has good flexibility and precision and is applicable to most parts. High precision mounters are generally of this type, but its speed cannot be compared with that of composite materials. Compared with parallel systems, the turntable is large. Arm type machines are divided into single arm type and multi arm type. The multi arm mounter developed on the basis of the single arm mounter can double the working efficiency.

SMT patch processing technology and process problems

What problems do we need to know about SMT chip processing technology? How can we fully understand patch processing technology? How can we fully understand the existing factors of these problems? Here are some points:

1: Mounting of SMT processing: Its function is to accurately mount SMT components to the fixed position of PCB. The equipment used is the mounting machine, which is located behind the screen printing machine in the SMT production line.

2: Patch processing dispensing: drop glue on the fixed position of PCB, which is mainly used to fix components on PCB. The equipment used is a glue applicator, which is located at the front end of the SMT production line or behind the test equipment.

3: Screen printing for patch processing: Its function is to print solder paste or patch adhesive onto the bonding pad of PCB to prepare for welding of components. The equipment used is the screen printing machine (screen printing machine) located at the front end of the SMT production line.

4: Curing of SMD processing: Its function is to melt the SMD adhesive, so that the surface mounted components and PCB board are firmly bonded together. The equipment used is a curing furnace, which is located behind the SMT mounter in the SMT production line.

SMT chip processing flow:

Installation: It is used to accurately install the surface mounting components to the fixed position on the PCB. The equipment used is the mounting machine, which is located behind the printing machine in the SMT production line.

Curing: Its function is to melt the patch adhesive, so that the surface mounted components and PCB board are firmly bonded together. The equipment used is a curing furnace, which is located behind the SMT mounter in the SMT production line.

Reflow soldering: Its function is to melt the solder paste, so that the surface mounted components and PCB board are firmly bonded together. The equipment used is a reflux furnace, which is located behind the SMT mounter in the SMT production line.

Printing: Its function is to print solder paste or paster on PCB pad to prepare for component welding. The equipment used is a printing machine (solder paste printing machine), which is located at the front end of the SMT production line.

Glue dispensing: Since most of the circuit boards used today are double-sided patches, in order to prevent the components on the input surface from falling off due to the remelting of solder paste when returning to the furnace for the second time, a glue dispenser is installed on the input surface to drop glue to the fixed position of the PCB. Its main function is to fix the components on the PCB. The equipment used is a glue applicator, which is located at the front end of the SMT production line or behind the test equipment. Cleaning: Its function is to remove solder residues harmful to human health on the assembled PCB, such as flux. The equipment used is a washing machine, which may not be fixed, and can be online or offline.

Check: Its function is to check the welding quality and assembly quality of the assembled PCB. The equipment used includes magnifying glass, microscope, on-line tester (ICT), flying probe tester, automatic optical inspection (AOI), X-ray testing system, function tester, etc. It can be configured at the appropriate position on the production line according to the detection needs.

Rework: Its function is to rework PCB board and fail to detect fault Tools used are soldering iron, rework station, etc