PCBA board bot surface and PCBA board division requirements

A PCBA board can be divided into top face and bot face. Strictly speaking, there is no accurate definition of top face and bot face. Let's talk about the bot face and top face of the PCBA board.

1、 What does bot face mean

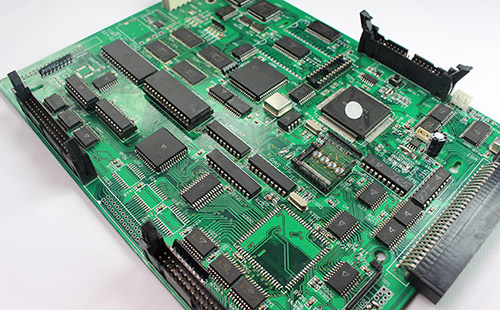

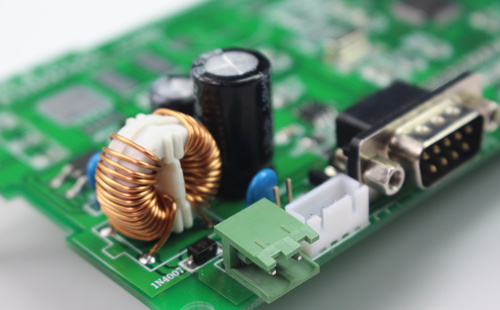

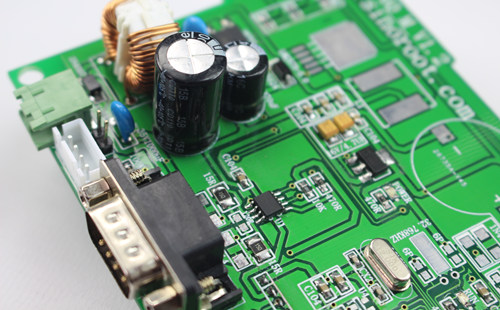

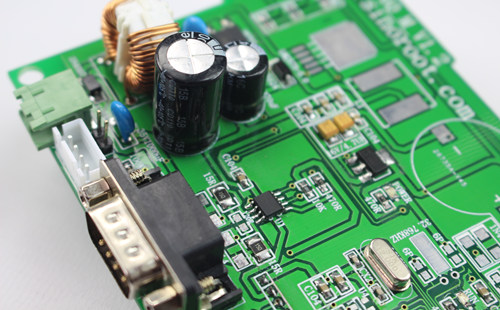

Generally speaking, the bot surface is the bottom surface of the PCBA board. There are few components or chips, and the weak side in function is the bot side. If it is a single panel, the side without components and wave soldering is the bot side.

2、 Correctly distinguish the top surface and bot surface of PCBA board

The top surface of the PCBA board is the top surface and the bot surface is the bottom surface. Generally speaking, there are more components or chips on the top side than on the bot side. The top side is the main side to realize functions, while the bot side is the relatively minor side.

The top side and bot side of the PCBA board are not strictly defined. This is just a general statement. I hope it will help you.

What are the requirements for PCBA boards?

Due to the small size of some PCB boards, they are often made into panels. After PCBA assembly and processing, PCBA panels need to be separated. The separation method is mainly divided into manual plate division and machine plate division. In the process of plate division, some precautions should be taken to prevent the intact PCBA board from being damaged.

1、 Requirements for manual plate division

1. When folding the edge of the plate, both hands must be used to hold the lower edge of the PCBA plate, which is 20mm from the V-cut, to avoid bending deformation, damage to the PCBA electrical circuit and parts, and tin path.

2、 Requirements for machine partition

1. Stable support point

Without support, the generated stress may damage the base plate and welding points. Twisting the plate or stressing the assembly during splitting can cause hidden or obvious defects.

2. Wear protective tools

Before operation, be sure to prepare for protection, and install high-frequency eye protection lighting devices to protect the safety of operators. You'd better wear a pair of eyes to protect your eyes.

3. Always wipe the machine spindle and cutter with alcohol to remove PCB dust generated in the board splitting process and maintain the normal operation of the board splitting machine.

4. After using for a certain number of times, oil the sliding rod and bearing of the board splitter to make them smooth, and check whether the screws are loose.

5. During the operation of the machine, the worktable should be kept clean, and it is better not to place other things on it, so as to avoid the damage of tools and objects caused by falling on the tools. Although there is an electric eye for maintenance, attention should be paid to a certain safety interval between fingers and tools in the process of use.

In general, when PCBA boards are divided, machine boards are more efficient and less damaged than manual boards. However, when the machine is divided, it is necessary to operate strictly according to the process to reduce human errors.

The PCB manufacturer, PCB designer and PCBA processor will explain the requirements for PCBA board bot surface and PCBA sub board.