PCBA proofing production cycle and searching for reliable PCBA proofing manufacturers

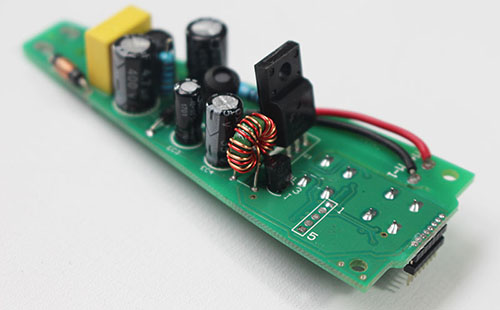

PCBA processing plants generally have a PCBA proofing process after customers establish cooperation. The number of PCBA samples is generally small, ranging from 5-20 pieces. Therefore, the production cycle of PCBA proofing is shorter than that of mass production. The fastest production cycle of PCBA proofing is 5-7 days.

The production cycle of PCBA proofing mainly consists of the following parts: PCB production time, component procurement time, SMT/DIP production time, and PCBA test time.

PCB proofing can be expedited for PCB manufacturers to achieve 2-3 deliveries, but normal PCB production takes 4-5 days; Purchased components are generally in stock, and generally arrive within 2-4 days; SMT and DIP1-2 days; PCBA test for 1 day.

The production cycle of PCBA proofing can achieve delivery in 5 days at the earliest, but the actual production period is related to whether the materials are scarce and the difficulty of processing.

How to find a reliable PCBA proofing manufacturer?

After completing the product design and before preparing for the market, electronic product developers will generally look for PCBA proofing manufacturers to produce product samples. Nowadays, there are countless PCBA proofing manufacturers, and their processing strength is uneven. How can we find reliable PCBA proofing manufacturers in the vast crowd?

1、 Degree of specialization of the factory

PCBA proofing is a relatively complex process, which requires the coordination and cooperation of all departments. From the degree of specialization of the factory, it can be seen whether the factory has the strength of product processing.

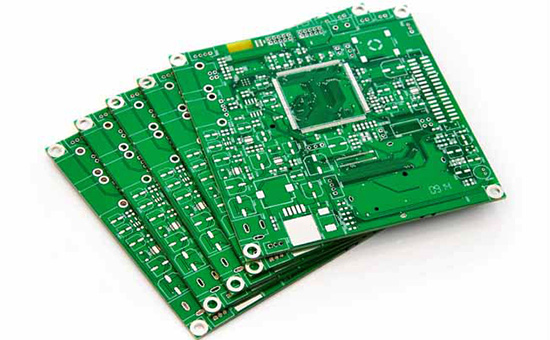

1. Whether there is professional equipment.

PCBA processing and production requires very professional equipment, such as high-speed mounter, multi temperature zone reflow soldering, AOI detector, ICT online tester and other equipment, which are the basis of production.

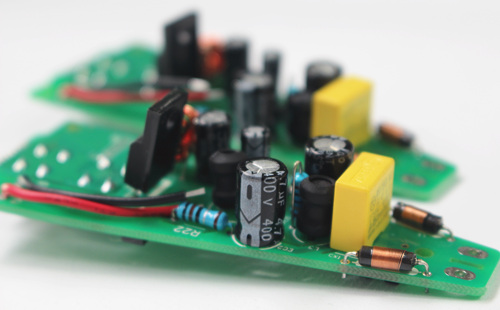

2. Whether there is professional process management

PCBA proofing production requires professional equipment and professional process management to control the quality. Generally, the better PCBA proofing manufacturers will be certified by ISO9001 quality management system, IPC-A-610E electronic assembly acceptance standard, etc. Whether there are SOP job instructions and other documents to guide the behavior of employees. We can roughly understand the strength of the factory's quality control by checking the factory's data documents and qualification certification.

2、 Service awareness

PCBA proofing manufacturers provide processing services rather than real products. A PCBA proofing manufacturer with a good sense of service can take the initiative to take responsibility when customers encounter problems, respond quickly and solve problems for customers. Therefore, the service awareness of a PCBA proofing manufacturer is very important. The service awareness of PCBA proofing manufacturers can be understood by understanding the company's corporate culture and the attitude of business personnel to customers.

3、 Industry experience

Today, the PCBA industry is going through great waves, and some poorly managed PCBA proofing manufacturers have begun to close down. The years of industry experience reflects the strength of a PCBA manufacturer to some extent. Secondly, it also depends on whether the products manufactured are high-end, mid-range or low-end, and which field of products are manufactured. We can judge whether the products are matched with their own. Only the right ones are the best.

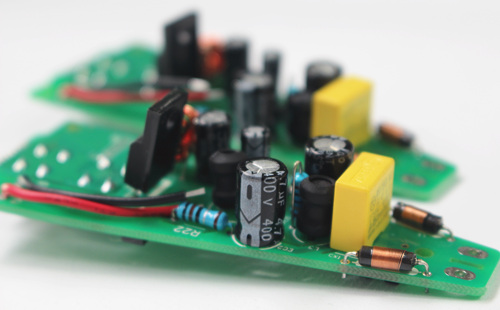

4、 Price

In the market, the price of PCBA proofing is relatively transparent, some are high, others are low, but the lower the price, the better. Some PCBA proofing manufacturers choose to purchase original components from formal channels and implement strict quality control, which will increase the cost of processing; In order to reduce the price, some PCBA proofing manufacturers may easily cut corners and lead to unstable quality. As the saying goes, we should choose the appropriate cost-effective PCBA proofing manufacturer according to our own situation.