Read PCBA fault analysis device knowledge in one article

1、 Overview of modern electronic assembly process

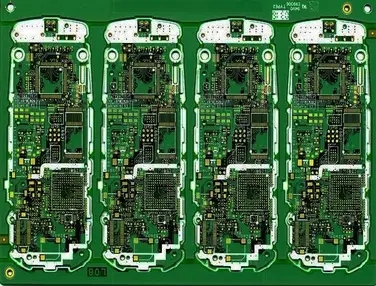

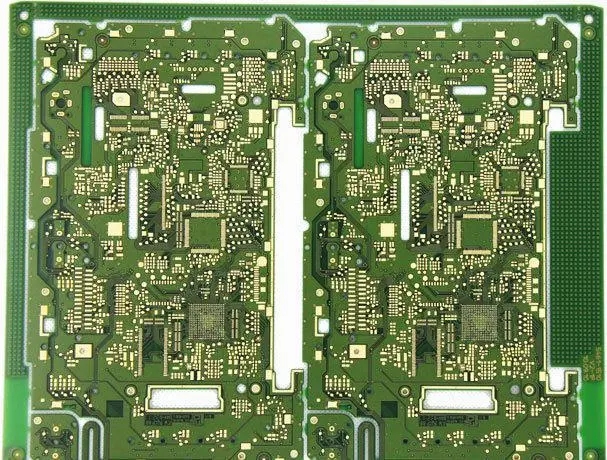

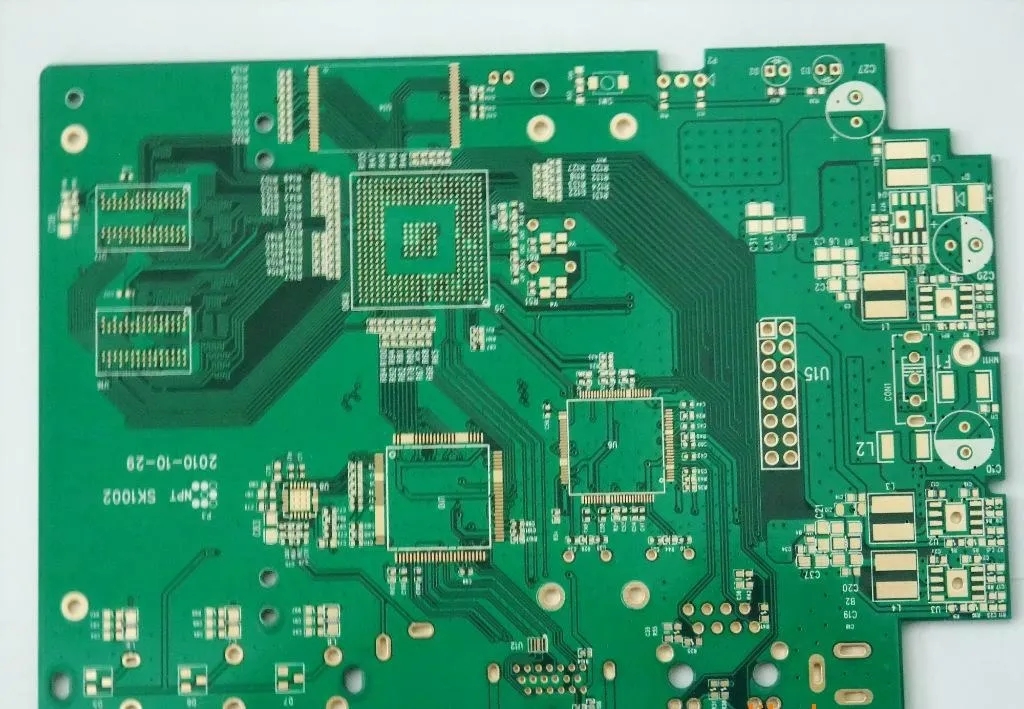

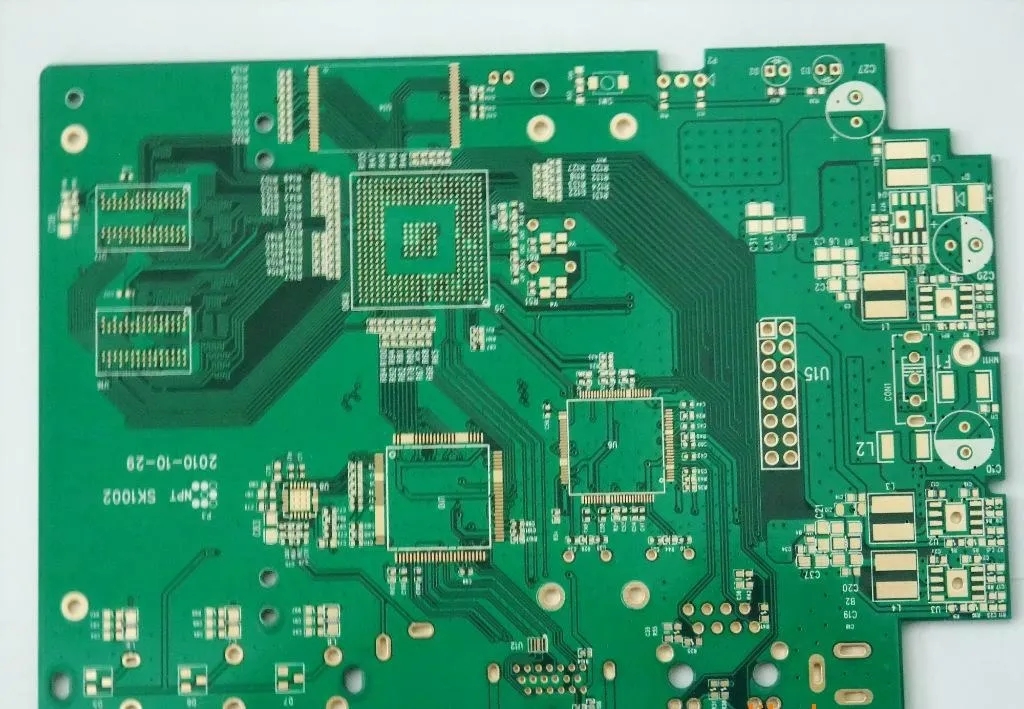

PCBA is mainly taken as the object of development. Therefore, the research on the reliability of electronic assembly process is also mainly focused on the failure phenomenon of PCBA.

PCBA failures can be divided into two categories: those occurring in the production process and those occurring during the service of users. (1) Failure phenomena of PCBA (internal or surface) during manufacturing: such as plate bursting, delamination, surface surplus, ion migration and chemical corrosion (rust). (2) A variety of failure modes and failure manifestations on PCBA during the service period of users: such as faulty soldering, brittle fracture of solder joints, microstructure degradation in solder joints, reliability degradation, etc.

2、 Purpose of fault analysis

Fault analysis is the process of determining the fault cause, collecting and analyzing data, and summarizing the fault mechanism that causes the failure of specific devices or systems.

The main purposes of fault analysis are:

Find out the cause of the fault;

Trace the adverse factors existing in process design, manufacturing process and user service;

Propose corrective measures to prevent reoccurrence of faults. Through the accumulated results of fault analysis, we will continuously improve the process design, optimize the product manufacturing process, and improve the usability of products, so as to achieve the goal of comprehensively improving the reliability of products.

3、 PCBA failure rate curve

1. PCBA product failure rate curve includes the following three levels, namely:

Component failure rate curve: the failure rate of components in the service period of users can be effectively reduced by forced aging of components before delivery.

Component supply life curve: it describes the service life of components after they arrive at users, which has a significant impact on the reliability of the constituent system.

PCBA assembly failure rate curve: it is jointly affected by SMD incoming material life, SMD assembly life and solder joint life. At this time, the service life of PCBA basically depends on the solder joint life. Therefore, ensuring the welding quality of each welding point is the key link to ensure the high reliability of the system.

2. Typical instantaneous failure rate curve of PCBA. Typical instantaneous failure rate of PCBA is referred to as PCBA typical failure rate. Instantaneous failure rate is the probability of PCBA failure in unit time after working to time t. The typical instantaneous failure rate curve of PCBA consists of three areas: premature aging area, product service area and aging area.

4、 Levels, principles and methods of PCBA failure analysis

1. The level of failure analysis In the production and application of electronic products, the control and analysis of PCBA and solder joint failures are basically the same as the reliability control and analysis methods of other systems.

2. Principle of failure analysis - basis of mechanism reasoning

Site information;

Analysis of retest (failure mode confirmation) results;

Failure mechanism of specific process and structure of the object;

Failure mechanism related to specific environment;

The relationship between failure mode and failure mechanism;

Long term accumulation of relevant knowledge and experience.

Failure Analysis of PCBA

3. Failure analysis method Some experts in the industry have summarized a good analysis model for the method used in PCBA failure analysis.