SMT Patch Processing Common Mmaterials Introduction

SMT chip processing customers are very concerned about the quality of processing, the quality of chip processing is the most important thing, but for SMT foundry materials, the choice of electronic components is also one of the key factors affecting product quality. Electronic processing is inseparable from electronic components, the selection of components is also one of the core issues, not only to ensure the quality of products, but also to control the cost within the budget, to achieve a balance between quality and cost. The following professional SMT processing factory Shenzhen Kingford Technology Co., Ltd. gives you a brief introduction to some common components of SMT patch processing.

Chip resistance Resistance is an electronic component with resistance characteristics, widely used in SMT chip processing. Resistors are divided into fixed resistors and variable resistors (potentiometers), which play the role of voltage balancing, shunt and current limiting in the circuit.

Chip Capacitor

Capacitors are also one of the basic components of SMT processing. It is a storage unit for electrical energy. It plays the role of coupling, filtering, DC and tuning in electronic circuits.

Induction coil is what we often say inductance, it can store magnetic energy. The inductor in SMT chip processing is usually composed of frame, winding, shield, iron core, etc. The resistance of the potentiometer can be changed. In theSMT process, the resistance needs to be continuously adjusted within a specified range, which is called a potentiometer. The potentiometer is composed of a shell, a sliding end, a rotating shaft, a ring resistor and three lead ends.

TransformerThe transformer is generally composed of an iron core and a coil, which has two or more windings, of which the winding connected to the power supply is called a primary coil, and the rest is called a secondary coil. When there is an AC current in the primary coil, an AC flux is generated in the magnetic core to induce voltage in the secondary coil. Transformers are mainly used for AC voltage conversion, current conversion, power conversion, impedance conversion and buffer isolation.

Crystal diodeThe crystal diode is composed of a PN junction, an electrode lead and an additional sealed enclosure, and has unidirectional conductivity.

Field-effect transistorsThis diode is also a PN junction semiconductor device. Unlike transistors, in chips machined by SMT, it does not utilize the electrical conductivity of the PN junction, but its insulating properties.

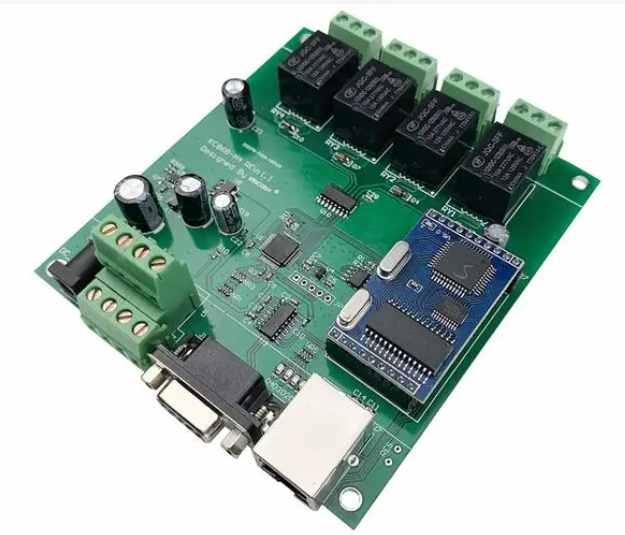

Shenzhen Kingford Technology Co., Ltd. specializes in providing integrated PCBA electronic manufacturing services, including upstream electronic component procurement to PCB production and processing, SMT patches, DIP plug-ins, PCBA testing, finished product assembly and other one-stop services.

The company gives full play to its competitive advantages in scale procurement and quality control, and has signed long-term cooperation agreements with many electronic component manufacturers at home and abroad and around the world to ensure the quality and stable supply of raw materials, and transfer the benefits to customers.

Long-term maintenance of IC, resistors, capacitors, inductors, audiodes and other components procurement advantages, can greatly save customers' inventory costs, improve production turnover efficiency, save time. Currently for the United States, Britain, Japan, Russia, France, Canada, Australia, Romania, Switzerland and other countries and regions to provide PCBA processing services.

We provide PCBA processing services, starting from PCB circuit board production, our own PCB manufacturers (obtained the extremely strict automotive industry TS16949 certification), focusing on the quality of the circuit board and PCBA quality control system.

Due to decades of experience in purchasing electronic components, we maintain long-term cooperation with large brands to ensure the original packaging and procurement channels of components. In the packaging process of components, the selection of thousands and Locai solder paste to ensure the reliability of welding, with automatic printing press, Panasonic high-speed placement machine, upper and lower eight temperature zone reflow, AOI automatic optical detector, can effectively ensure the reliability and quality of electronic packaging process. In addition, perfect IPC, IPQC, OQA and other management processes, clear job responsibilities, strict implementation of IPC electronic assembly acceptance standards. For PCBA testing, we have professional engineers to perform 100% batch testing using a variety of test stands, including channels, noise, amplitude, signal, temperature, humidity, drop or to perform customer-specific test plans. All efforts are aimed at becoming a refined PCBA processing factory.