SMT Chip Processing Tips

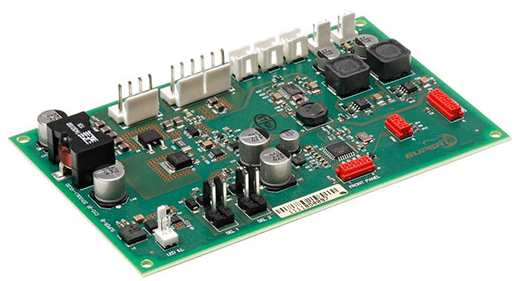

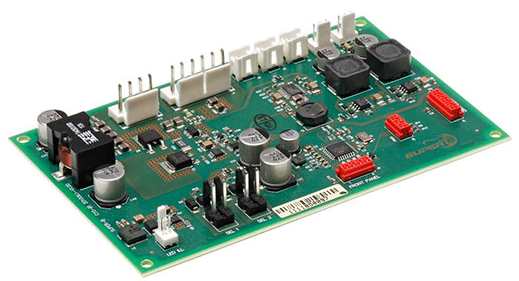

SMT processing plants play an important role in the electronics processing industry and are indispensable for the precision and miniaturization of electronic products. Patch processing electronic components also have many advantages over traditional plug-in components. Next, PCBA processing manufacturer Shenzhen Kingford Technology Co., Ltd. introduces the small knowledge in SMT chip processing.

Commonly used Mark shapes are: square, circle, "ten" shape, swastig, diamond, triangle;

In the preheating area and cooling area of SMT processing, due to the wrong setting of Reflow Profile, the parts will crack;

When the chip is processed, the uneven heat at both ends of the parts is easy to cause: deviation, empty welding, stone tablet;

Tools for repairing patch components are: electric soldering iron, hot air workbench, tin gun, tweezers;

QC testing of PCBA processing plant is divided into: IQC, IPQC, FQC and OQC;

High speed mounter can mount resistors, capacitors, ics and transistors;

The characteristics of static electricity: all are small current and are greatly affected by humidity;

The Cycle time of high-speed SMT machine and ordinary SMT machine should be balanced as far as possible;

Quality is defined by doing it right the first time;

The SMT machine should stick small components first, and then stick large components;

BIOS is a basic Input/ Output System, the full English name: Base Input/ Output System;

The chip components can not be divided into LEAD and LEADLESS two kinds according to the | pin;

There are three basic types of common active placement machines: continuous placement type, continuous placement type and multi-transfer placement machine;

In SMT processing, it can be produced without LOADER;

The process of SMT processing is plate feeder - solder paste printing machine - high SMT machine - reflow welding - receiving machine;

When the humidity sensitive parts are opened, the color displayed in the humidity card circle is blue, and the parts can be used.

Shenzhen Kingford Technology Co., Ltd. specializes in providing integrated PCBA electronic manufacturing services, including upstream electronic component procurement to PCB production and processing, SMT patches, DIP plug-ins, PCBA testing, finished product assembly and other one-stop services.

Strength Guarantee

▪ SMT workshop: with imported SMT machines and a variety of optical testing equipment, it can produce 4 million points per day. Each process is equipped with QC personnel who can keep a close eye on product quality.

▪ DIP production line: There are two wave soldering machines. Among them, there are more than 10 old employees who have worked for more than three years. Skilled workers can weld all kinds of plug-in materials.

Quality assurance, high cost performance

▪ High-end equipment can mount precision parts, BGA, QFN, 0201 materials. Proof can be machine paste, also can hand swing.

▪ Samples and large and small batches can be produced. Proofing starting price 800 yuan, batch starting price 0.008 yuan/point, no start-up fee.

Rich Experience In SMT And Welding Of Electronic Products, Stable Delivery Time

▪ Accumulated service for thousands of home appliance subsidiaries, involving various types of automotive equipment and industrial control motherboard SMT processing services. Products are often exported to Europe and the United States, and the quality is affirmed by new and old customers.

▪ On-time delivery, generally delivered within 3-5 days after the board is assembled, small batch expedited can also be shipped on the same day.

Strong Maintenance Ability, Perfect After-Sales Service

▪ Experienced maintenance engineers can repair bad products caused by various welding problems, and can ensure the connectivity of each circuit board.

▪ 24-hour customer service staff will be ready to respond and resolve your order as soon as possible.