Electronic product developers in the PCBA processing plant proofing or small batch production, often hear machine fees and engineering costs, then these two fees refer to what part of the cost? The workshop will carry out non-stop production, the stoppage of the machine, the line change, are increasing the cost of production, reduce profits, therefore, for some relatively small batch orders often charge machine fees.

Engineering costs refer to the production of data files, the production of steel mesh, equipment debugging, SMT line change, because the order is too small, did not reach the minimum consumption level, the customer needs to bear these engineering costs. Strength guarantee

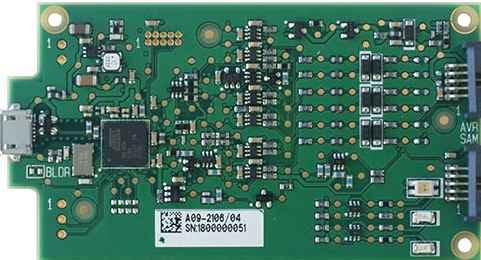

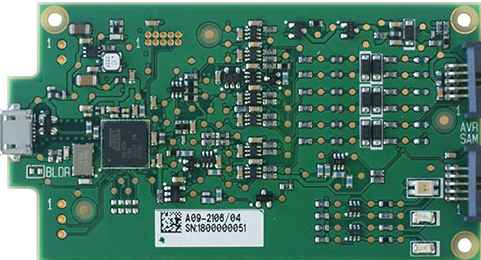

1.SMT workshop: With imported SMT machines, optical inspection equipment, can produce 4 million points per day. Each process is equipped with QC personnel, who can keep an eye on product quality.

▪DIP production line: there are two wave soldering, of which there are more than 10 old employees who have worked for more than three years. The workers have high proficiency and can weld all kinds of plug-in materials.

2. Quality assurance, cost-effective

▪ High-end equipment can be attached to precision shaped parts, BGA, QFN, 0201 materials. Also can be template patch, loose material hand. Sample and size batch can be produced, proofing from 800 yuan, batch 0.008 yuan/point, no start-up fee.

3. Rich experience in SMT and welding of electronic products, stable delivery

▪ Accumulated service for thousands of electronic enterprises, involving many types of automotive equipment and industrial control motherboard SMT processing services, products are often exported to Europe and the United States, quality can be affirmed by new and old customers.

▪ Punctual delivery, normal 3-5 days after complete materials, small batches can also be expedited on the same day.

4. Strong maintenance ability, perfect after-sales service

▪ Experienced maintenance engineers can repair all kinds of patch welding caused by bad products, to ensure the connectivity of each circuit board.

▪ 24-hour customer service staff responds at any time to solve your order problems as quickly as possible.

1.Factory scale:If you want to do PCBA processing, the necessary equipment and scale are essential. The production scale and equipment perfection of a PCBA processing plant can intuitively judge the strength of this factory, and it is a good choice to find a strong PCBA processing plant as a supplier.

2. Staff quality:

The factory with strong hardware strength is not the only standard for a reliable PCBA processing plant, but also must have professional business personnel to dock with us, timely understand our needs, and quickly deal with various sudden problems. Good communication is the premise of long-term cooperation, after all, professional people do professional things the most reliable.

3. Service attitude:A good attitude is an indispensable foundation and prerequisite for providing reliable products. PCBA processing plant service attitude is good, in order to calm down to do products.

4. Quality control:

Reliable PCBA processing plants will not allow faulty PCB boards to enter the market. They rely here on quality control capabilities, from the quality control of raw materials, to the quality control during production and processing, to the quality control of the final product before it leaves the factory. This is essential, so when we choose a PCBA processing plant, we must choose a company with a complete quality control process.