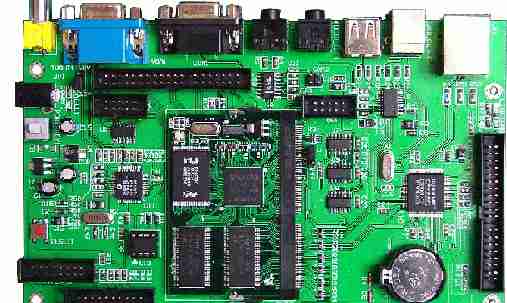

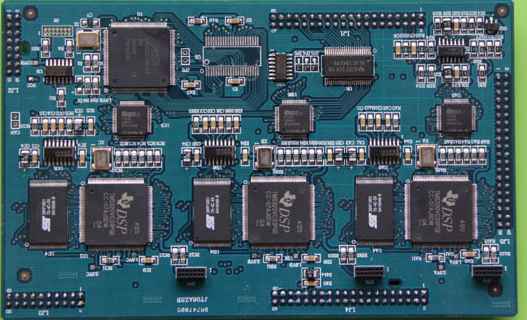

SMT chip processing is one of the most widely used technologies in the electronics manufacturing industry. The quality of SMT processing will directly affect the production efficiency of the entire electronic manufacturing industry, so the quality of SMT processing must be paid attention to. However, in the process of SMT patch processing, the phenomenon of poor tin penetration often occurs. This article will introduce in detail the four types of reasons for poor tin penetration in SMT processing plants.

1.Material problem

Poor tin penetration may result from problems with the patch parts themselves. Because the manufacturing process of some patch parts is not strict or the quality is not up to standard, the solder paste on the surface of the patch parts is not good enough, which leads to poor tin penetration during SMT patch processing.

Carefully inspect the quality of the parts, investigate the credibility of the manufacturer, and collect feedback on the patch parts through as many channels as possible. In addition, classification management should also be carried out according to the batch of patch parts to ensure quality stability between batches.

2. The device is faulty

The operation and maintenance of SMT chip processing equipment is also another major factor in poor tin penetration. The quality and stability of the equipment will directly affect the control of the temperature, pressure, process and other parameters of the patch parts. If the processing capacity of the equipment is insufficient, the heating of the patch parts is not uniform enough, and the temperature of different parts is different, which causes poor tin penetration.

The solution to equipment problems is to purchase and operate equipment according to equipment performance and process requirements. The stability and quality of the equipment should be an important consideration when purchasing the equipment, and regular maintenance and inspection should also be carried out to ensure the normal operation of the equipment.

3. Process issues

In order to reduce the risk of poor tin penetration in SMT chip processing, an accurate process parameter control scheme should be established to reduce the number of parameter adjustments and ensure the stability of the processing process.

4. Operation problems

The operation process of SMT patch processing is also one of the possible factors of poor tin penetration. Staff lack of professional knowledge, improper operation, will destroy the solder paste on the surface of the parts, resulting in poor tin penetration and other problems.

In order to improve the skill level of operators, the training and education of operators should be strengthened, and their skills should be evaluated and supervised regularly. In addition, it is necessary to establish scientific operation norms and strictly supervise the operation process.

To sum up, poor tin penetration is a common problem in SMT patch processing. In order to solve this problem, it is necessary to consider the four aspects of materials, equipment, process and operation, and reduce unnecessary risks in every aspect as much as possible.