In SMT processing, the use of solder paste and red glue is a common welding material, they play a vital role in the manufacture and assembly of electronic equipment. However, many people do not know the difference between these two materials, next we will explore the difference between the use of solder paste and red glue in SMT processing to help you better understand the difference between these two welding materials.

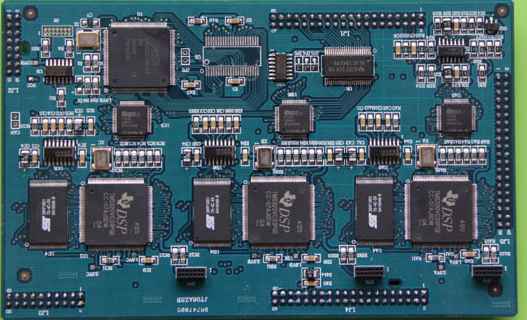

First, let's look at the solder paste. Solder paste is a very common welding material, it is a kind of fine particles of solder and flux mixed into a viscous substance. Solder paste can be divided into two types: lead-free and leaded. Lead-free solder paste is developed under the requirements of environmental protection, and its main components are Sn, Ag, Cu and other metal materials and some flux. Leaded solder paste consists of Sn and Pb metal materials and some flux. The role of the solder paste is to form a sticky solder layer on the pin or pad of the electronic component, so as to realize the connection of the component and the PCB board.

Next, let's look at red glue. Red glue is a thermosetting adhesive commonly used in the assembly and repair of electronic devices. The main components of red gum are epoxy resin, polyimide, silicone rubber and other materials. Unlike solder paste, red glue is a non-conductive material, mainly used for fixing and insulating electronic components. The use of red glue usually requires heating to thermoset it, thus forming a strong bonding layer.

In SMT processing, solder paste and red glue have their own advantages and disadvantages. The main advantage of solder paste is the ability to connect electronic components in a short time, thereby improving production efficiency. In addition, the solder paste has a high welding strength and is able to maintain a stable connection in extreme environments. However, the disadvantage of solder paste is that it is not suitable for all types of electronic components. Some special components, such as high-frequency components and high-power components, need to use special welding materials to ensure the quality and stability of their connections.

In contrast, the main advantage of red glue is the ability to provide better insulation and protective properties when fixing components, thus protecting electronic components from the external environment. In addition, red glue is usually more flexible than solder paste and can adapt to different components and application scenarios. However, there are some limitations to the use of red glue. Since red glue requires heating to thermoset, in some special components and application scenarios, red glue may cause excessive heating and thermal damage, which affects the performance and life of components.

In addition to the above advantages and disadvantages, solder paste and red glue are also different in terms of use and process flow. When using solder paste for SMT processing, it is usually necessary to use a printing press to evenly print the solder paste on the pad of the PCB board. Then, the electronic components are placed on the pad and hot melted by a hot blast furnace or a reflux furnace, so that the solder paste is thermoset and the connection is formed.

When using red glue for SMT processing, it is usually necessary to first paint the red glue on the PCB board or the surface of the components. Then the components are placed on the PCB board and fixed. Finally, it is heated by hot blast stove or other heating equipment, so that the red glue is thermoset, forming a fixed and insulating effect.

It should be noted that when using solder paste and red glue for SMT processing, the appropriate materials and processes must be selected according to the specific components and application scenarios. If used improperly, it will not only affect the performance and life of the product, but also may lead to some unpredictable safety hazards.

In summary, solder paste and red glue have their own advantages and disadvantages and scope of application in SMT processing. It is necessary to select the appropriate welding materials and processes according to the specific situation to ensure the stability, reliability and safety of electronic equipment. In the selection of materials and processes, we should also pay attention to the requirements of environmental protection and energy saving, and choose materials and processes that meet the standards.