PCB design software features to ensure design integrity

This article "PCB Design Software Features to Ensure Design Integrity" is edited by kinhford Electronic Technology Co., LTD. PCBA author, welcome to read the following details.

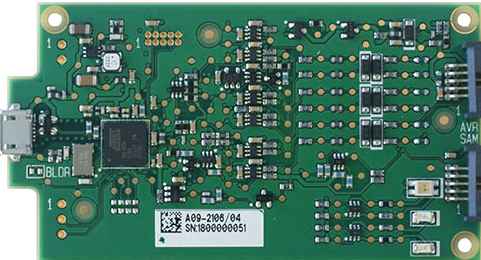

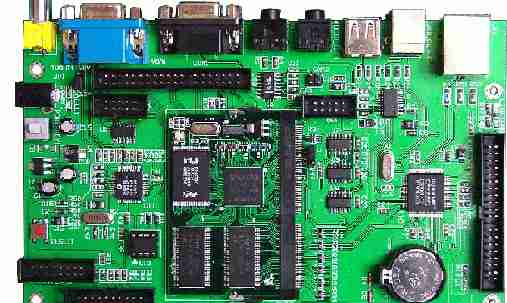

When building an electronic circuit board, design integrity must be maintained throughout the process. PCBA development process. Each stage of the design-build testing (DBT) process should reflect the designer's original intent. To this end, your PCB design software should include features that enable you to incorporate all the necessary data and information into a design file or package.

The best PCBA design not only meets performance requirements. Instead, the best board designs incorporate the designer's intent by converting the design and all necessary supporting data into CM format. Promote manufacturability while maintaining the integrity of the original design. The extent to which these goals are achieved depends on the establishment of your CM and symbiotic relationships, as well as the PCB design software used and its capabilities.

Accurately passing the  https://www.kingfordpcb.com/yuan.phpdesign intent to your CM is the best PCBA, which is the defining step of the board manufacturing stage. Therefore, assembly is the final condition that determines the build status of the board and is responsible for ensuring that your design requirements are met. Assembly, as well as the entire manufacturing process, is most efficient when there is an open, transparent, and collaborative environment between developers and CM. This is called white box manufacturing and depends on availability, ease of access and compliance with CM's DFM and DFA rules and guidelines.

https://www.kingfordpcb.com/yuan.phpdesign intent to your CM is the best PCBA, which is the defining step of the board manufacturing stage. Therefore, assembly is the final condition that determines the build status of the board and is responsible for ensuring that your design requirements are met. Assembly, as well as the entire manufacturing process, is most efficient when there is an open, transparent, and collaborative environment between developers and CM. This is called white box manufacturing and depends on availability, ease of access and compliance with CM's DFM and DFA rules and guidelines.

In addition, design integrity also depends on the design software used to create your design file or package. The functional differences between different EDA programs may be greater than you think. Although most programs today include basic features such as symbol and landing page creation, postnotes between board and schematic design, auto placement, and auto wiring, advanced features are often not available to help your CM.

Select PCB design software to meet design integrity requirements

Ensure that the following basic features are present in the PCB design software to facilitate translation and incorporation of design intent:

Basic PCB design software features for design integrity

1. Real-time component information

A key area of design integrity is optimal component selection. Lack of this information may delay making late development design changes.

2. Comprehensive component library import

While the ability to create new group symbols and landing patterns is critical to EDA functionality, it is equally important that your software achieve full functionality. PCB component procurement guidelines

3. Easy/simple DFM and DFA import

To support and promote optimal development and manufacturability, you should acquire and leverage your CM DFM and DFA.

4. Real-time DRC Most leading CMS automatically perform DFM checks on your design package. However, you can extend this process by: checking the design rules during the design process. If these checks can be performed in real time, errors can be corrected before they become entrenched and difficult to track and identify.

5. Forward and Backward annotation schematics and the ability to instantly reflect changes or corrections on the schematics are invaluable tools for creating efficient designs.

6. Circuit Analysis capabilities Many of today's leading EDA programs lack extensive circuit analysis capabilities. It is useful to provide PDN information or heat distribution; However, advanced circuit analysis capable of performance testing is a distinct advantage.

7. Digital Twin Viewing

Digital twin technology is finding its way into the PCBA design process. This 3D perspective allows potential problems to be identified or discovered before manufacturing begins.

8. Panel design ability

Another way to maintain design intent and help your CM is to consider panelization during the design process - if your software has that feature.

The use of the above features will go a long way in maintaining the integrity of your design throughout the development of your PCBA design. Even if your program doesn't have all the features, the more of these features you can take advantage of, the closer the built-in board gets to your original concept.