SMT plant will introduce you how to make tin full on PCBA proofing

In the process of PCBA proofing, the solder joint is not full, which will affect the performance and appearance of the circuit board. Next, kinhford Electronics, SMT patch factory, will analyze the common reasons why tin is not full on PCBA proofing. We believe that these problems can be avoided and tin full on PCBA proofing can be achieved. https://www.kingfordpcb.com/yuan.php?time=1685521494

https://www.kingfordpcb.com/yuan.php?time=1685521494

Common cause of tin not full on PCBA proofing

1. If the wettability of the flux used is not up to the standard when welding the solder paste, the tin will not be full when soldering.

2. If the flux activity in the solder paste is not enough, it will not be able to better remove the oxidation substances on the PCB pad, which will also cause a certain impact on the tin.

3. If the expansion rate of flux is very high when entering PCBA processing, the phenomenon of cavity will appear easily.

4. If the PCB pad or SMD welding site appears serious oxidation phenomenon, it will also affect the tinning effect.

5. If the amount of solder paste used is too little, it will also make the tin not full enough, there is a vacancy, this point as long as the experienced operator will not appear this mistake.

6. If the solder paste is not fully stirred before use, and the flux and tin powder are not fully integrated, it will also lead to some solder joints of the tin is not full.

1. Strength guarantee

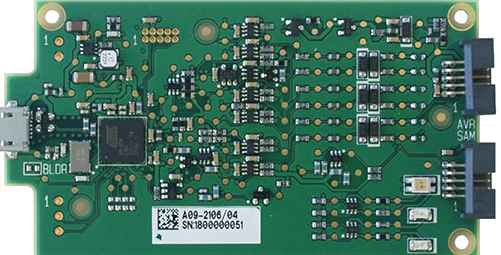

▪SMT workshop: We have imported SMT machines and several sets of optical inspection equipment, with a daily output of 4 million. Each process is equipped with QC personnel, who can keep an eye on product quality.

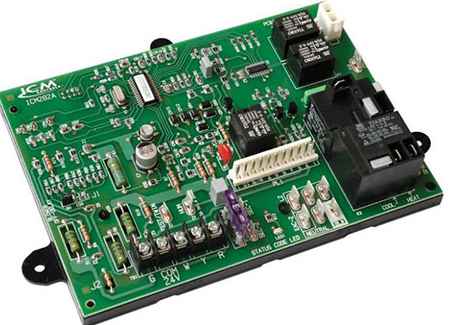

▪DIP production line: We have two wave-soldering machines, among which there are more than 10 old employees who have worked for more than three years. The skilled workers can weld all kinds of plug-in materials.

2. Quality assurance, cost-effective

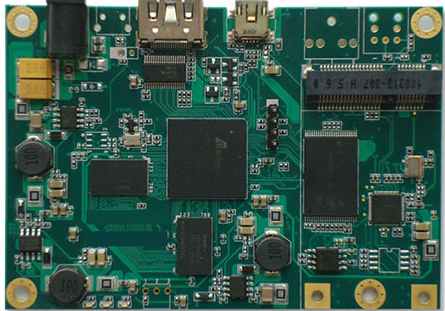

▪ High-end equipment can stick precision shaped parts, BGA, QFN, 0201 materials. Can also template patch, loose material hand.

▪ Sample and size batch can be produced, proofing from 800 yuan, batch 0.008 yuan/point, no start-up fee.

3. Rich experience in SMT and welding of electronic products, stable delivery

▪ Accumulated SMT SMT processing services for thousands of electronic enterprises, involving many kinds of automotive equipment and industrial control motherboard. The products are often exported to Europe and the United States, and the quality can be affirmed by new and old customers.

▪ On time delivery, normal 3-5 days after complete materials, small batch can also be expedited on the same day shipment.

4. Strong maintenance ability and perfect after-sales service

▪ Experienced maintenance engineers can repair all kinds of patch welding caused by bad products, to ensure the connection rate of each piece of circuit board.

▪ 24-hour customer service staff at any time response, the fastest speed to solve your order problems.