What is the preparation work before SMT patch processing?

In order to ensure the smooth processing and production of SMT patches, we need to do some preparatory actions before the formal production. The next professional PCBA manufacturer -kinhford Electronics for you to analyze the SMT patch processing before the preparatory work.

1. SMT workshop supervisor arranges workshop plan https://www.kingfordpcb.com/yuan.php?time=1685523029

https://www.kingfordpcb.com/yuan.php?time=1685523029

The workshop supervisor of SMT patch processing and production shall reasonably arrange the workshop plan according to the weekly and monthly plan of PMC department and the material supply situation, and arrange the elongation of each line body and technicians in the workshop.

2. Check and confirm the means of production

According to the production plan issued by the team leader and technical personnel, make preparations in advance, check whether there is steel mesh, whether the serial number is printed well, and determine the BOM list, the procedures of the SMT machine and the production process in advance.

3. Check production materials

According to the production plan issued by the workshop, the material clerk shall check the list of production materials combined with the ingredients, and send it to each line after the inventory is completed. According to the technical requirements, the temperature return of tin paste and red glue shall be made in advance.

4. Preprogramming of the patch machine

According to the weekly and monthly plan of the planning department, the equipment engineer prepared the program for the new product proofing in advance.

5. Preparatory material and steel mesh test

According to workshop plan, the operator prepared the next work order materials, steel mesh gage and tension test in advance.

6. Patch machine debugging

Before production, the technician shall put the program backed up in the computer into the placement machine and switch it in and out, adjust the track thimble of the placement machine well, check whether there are springboards and other errors in the program, and then load the material after confirming that they are correct, and adjust the temperature of reflow welding products into and out, and adjust the track well.

7. Check the whole process

Before production, technicians shall check the printing quality of solder paste and red glue of the printing operator and whether the material of the SMT machine is good. After placing FEEDER specifications, SMT SMT processing can start production after all are confirmed.

SMT patch factory should make the above preparation so as not to affect the production schedule of customers and their own production plan. kinhford Electronics provides SMT patch processing service to ensure the quality and delivery time of products. Please feel free to give the products to us for production. Online customer service will be waiting for you to contact us!

1. Strength guarantee

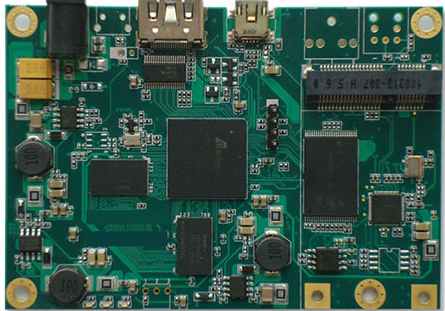

▪SMT workshop: We have imported SMT machines and several sets of optical inspection equipment, with a daily output of 4 million. Each process is equipped with QC personnel, who can keep an eye on product quality.

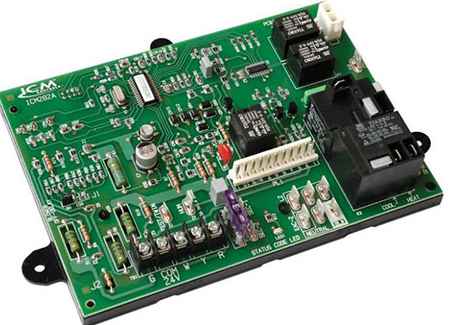

▪DIP production line: We have two wave-soldering machines, among which there are more than 10 old employees who have worked for more than three years. The skilled workers can weld all kinds of plug-in materials.

2. Quality assurance, cost-effective

▪ High-end equipment can stick precision shaped parts, BGA, QFN, 0201 materials. Can also template patch, loose material hand.

▪ Sample and size batch can be produced, proofing from 800 yuan, batch 0.008 yuan/point, no start-up fee.

3. Rich experience in SMT and welding of electronic products, stable delivery

▪ Accumulated SMT SMT processing services for thousands of electronic enterprises, involving many kinds of automotive equipment and industrial control motherboard. The products are often exported to Europe and the United States, and the quality can be affirmed by new and old customers.

▪ On time delivery, normal 3-5 days after complete materials, small batch can also be expedited on the same day shipment.

4. Strong maintenance ability and perfect after-sales service

▪ Experienced maintenance engineers can repair all kinds of patch welding caused by bad products, to ensure the connection rate of each piece of circuit board.

▪ 24-hour customer service staff at any time response, the fastest speed to solve your order problems.