I. Equipment configuration of SMT plant

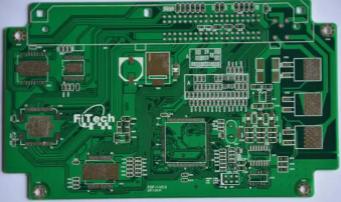

SMT plant equipment configuration mainly includes SMT SMT machine, welding machine, AOI testing machine, X-ray manipulator, fan tester and so on.

1. Selection of SMT placing machine. SMT SMT machine selection is the foundation of SMT plant, should be based on the production of product type and output to choose. Generally speaking, the selection of the patch machine is based on the patch speed, accuracy, range and the functional configuration of the patch machine.

2. Selection of welding machine. The selection of welding machine is also the basis of SMT plant, the general choice of welding technology, welding range, welding speed, welding precision, welding quality, etc.

3, AOI detection machine. AOI test machine is an indispensable equipment for SMT plant, its function is to automatically test PCB board, to ensure the quality of PCB board. The selection of AOI detector depends on the detection accuracy, detection range, detection speed and the functional configuration of the detection instrument.

4. X-ray manipulator. The selection of X-ray manipulator is based on the detection accuracy, detection range, detection speed and functional configuration of the detection instrument. It helps SMT plant to carry out seal detection and defect detection on PCB board.

5, fan tester. Fan tester can help SMT plant test the fans of products to ensure the quality of products, and can set the parameters according to the requirements of customers, so as to better meet the needs of customers.

Ii. On-site management of SMT plant

1. Security management. In the aspect of site management, SMT plant shall first conduct safety training for employees to ensure safe production; Secondly, a strict safety system should be established and strictly implemented to ensure safe production.

2. Quality management. SMT plant shall establish strict quality management system and strictly implement relevant regulations in field management to ensure product quality.

3. Process management

SMT plant shall establish a strict process management system and strictly implement relevant regulations in field management to ensure the correctness and effectiveness of the production process.

SMT plant shall establish a strict process management system and strictly implement relevant regulations in field management to ensure the correctness and effectiveness of the production process.

5. Material Management SMT plant shall establish a strict material management system and strictly implement relevant regulations in field management to ensure the timely supply and rational use of materials.

Iii. Production management of SMT plant

1. Plan management. In terms of production management, the SMT plant shall establish a plan management system and strictly implement relevant regulations to ensure the correctness and effectiveness of the plan.

2. Capacity management. In terms of production management, SMT plant shall establish a strict capacity management system and strictly implement relevant regulations to ensure the standard and rational utilization of capacity.

3. Cost management. In terms of production management, SMT plant shall establish a strict cost management system and strictly implement relevant regulations to ensure reasonable cost expenditure and control.

4. Financial management. In terms of production management, SMT plant shall establish a strict financial management system and strictly implement relevant regulations to ensure the correctness and effectiveness of finance.

3. Human Resource management. In terms of production management, the SMT plant shall establish a strict human resource management system and strictly implement relevant regulations to ensure the rational allocation and effective utilization of human resources. What equipment configuration does SMT plant have? SMT plant production management

I. Equipment configuration of SMT plant

SMT plant equipment configuration mainly includes SMT SMT machine, welding machine, AOI testing machine, X-ray manipulator, fan tester and so on.

1. Selection of SMT placing machine. SMT SMT machine selection is the foundation of SMT plant, should be based on the production of product type and output to choose. Generally speaking, the selection of the patch machine is based on the patch speed, accuracy, range and the functional configuration of the patch machine.

2. Selection of welding machine. The selection of welding machine is also the basis of SMT plant, the general choice of welding technology, welding range, welding speed, welding precision, welding quality, etc.

3, AOI detection machine. AOI test machine is an indispensable equipment for SMT plant, its function is to automatically test PCB board, to ensure the quality of PCB board. The selection of AOI detector depends on the detection accuracy, detection range, detection speed and the functional configuration of the detection instrument.

4. X-ray manipulator. The selection of X-ray manipulator is based on the detection accuracy, detection range, detection speed and functional configuration of the detection instrument. It helps SMT plant to carry out seal detection and defect detection on PCB board.

5, fan tester. Fan tester can help SMT plant test the fans of products to ensure the quality of products, and can set the parameters according to the requirements of customers, so as to better meet the needs of customers.

Ii. On-site management of SMT plant

1. Security management. In the aspect of site management, SMT plant shall first conduct safety training for employees to ensure safe production; Secondly, a strict safety system should be established and strictly implemented to ensure safe production.

2. Quality management. SMT plant shall establish strict quality management system and strictly implement relevant regulations in field management to ensure product quality.

3. Process management. SMT plant shall establish a strict process management system and strictly implement relevant regulations in field management to ensure the correctness and effectiveness of the production process.

4. Process management. SMT plant shall establish a strict process management system in field management and strictly implement relevant regulations to ensure the correctness and effectiveness of the production process.

5. Material management. SMT plant shall establish strict material management system and strictly implement relevant regulations in field management to ensure timely supply and reasonable use of materials.

Iii. Production management of SMT plant

1. Plan management. In terms of production management, the SMT plant shall establish a plan management system and strictly implement relevant regulations to ensure the correctness and effectiveness of the plan.

2. Capacity management. In terms of production management, SMT plant shall establish a strict capacity management system and strictly implement relevant regulations to ensure the standard and rational utilization of capacity.

3. Cost management. In terms of production management, SMT plant shall establish a strict cost management system and strictly implement relevant regulations to ensure reasonable cost expenditure and control.

4. Financial management. In terms of production management, SMT plant shall establish a strict financial management system and strictly implement relevant regulations to ensure the correctness and effectiveness of finance.

3. Human Resource management. In terms of production management, the SMT plant shall establish a strict human resource management system and strictly implement relevant regulations to ensure the rational allocation and effective utilization of human resources. What equipment configuration does SMT plant have? SMT plant production management

I. Equipment configuration of SMT plant

SMT plant equipment configuration mainly includes SMT SMT machine, welding machine, AOI testing machine, X-ray manipulator, fan tester and so on.

1. Selection of SMT placing machine. SMT SMT machine selection is the foundation of SMT plant, should be based on the production of product type and output to choose. Generally speaking, the selection of the patch machine is based on the patch speed, accuracy, range and the functional configuration of the patch machine.

2. Selection of welding machine. The selection of welding machine is also the basis of SMT plant, the general choice of welding technology, welding range, welding speed, welding precision, welding quality, etc.

3, AOI detection machine. AOI test machine is an indispensable equipment for SMT plant, its function is to automatically test PCB board, to ensure the quality of PCB board. The selection of AOI detector depends on the detection accuracy, detection range, detection speed and the functional configuration of the detection instrument.

4. X-ray manipulator. The selection of X-ray manipulator is based on the detection accuracy, detection range, detection speed and functional configuration of the detection instrument. It helps SMT plant to carry out seal detection and defect detection on PCB board.

5, fan tester. Fan tester can help SMT plant test the fans of products to ensure the quality of products, and can set the parameters according to the requirements of customers, so as to better meet the needs of customers.

Ii. On-site management of SMT plant

1. Security management. In the aspect of site management, SMT plant shall first conduct safety training for employees to ensure safe production; Secondly, a strict safety system should be established and strictly implemented to ensure safe production.

2. Quality management. SMT plant shall establish strict quality management system and strictly implement relevant regulations in field management to ensure product quality.

3. Process management. SMT plant shall establish a strict process management system and strictly implement relevant regulations in field management to ensure the correctness and effectiveness of the production process.

4. Process management. SMT plant shall establish a strict process management system in field management and strictly implement relevant regulations to ensure the correctness and effectiveness of the production process.

5. Material management. SMT plant shall establish strict material management system and strictly implement relevant regulations in field management to ensure timely supply and reasonable use of materials.

Iii. Production management of SMT plant

1. Plan management. In terms of production management, the SMT plant shall establish a plan management system and strictly implement relevant regulations to ensure the correctness and effectiveness of the plan.

2. Capacity management. In terms of production management, SMT plant shall establish a strict capacity management system and strictly implement relevant regulations to ensure the standard and rational utilization of capacity.

3. Cost management. In terms of production management, SMT plant shall establish a strict cost management system and strictly implement relevant regulations to ensure reasonable cost expenditure and control.

4. Financial management. In terms of production management, SMT plant shall establish a strict financial management system and strictly implement relevant regulations to ensure the correctness and effectiveness of finance.

3. Human Resource management. In terms of production management, the SMT plant shall establish a strict human resource management system and strictly implement relevant regulations to ensure the rational allocation and effective utilization of human resources.