PCBA processing plant refers to the production of printed circuit boards, chip circuit boards, whole board assembly and all kinds of electronic components processing and assembly factory. The main product categories of PCBA processing plant involve consumer electronics, industrial control equipment, communication equipment, electrical electronics, robotics and other fields. These products involve more electronic components, so the process technology and equipment requirements of PCBA processing plants are relatively high.

I. Process of PCBA processing plant

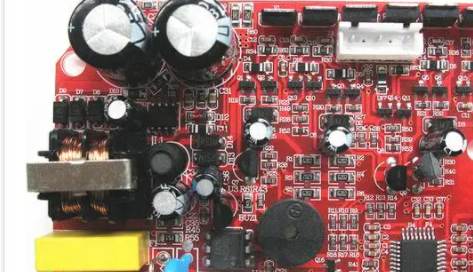

The processing process of PCBA processing plant is generally divided into three stages: printed circuit board processing, chip circuit board processing, whole board assembly, each stage has its professional technology and equipment, and finally all kinds of electronic components assembled on the whole board.

1. Printed circuit board processing: Printed circuit board is composed of circuit diagram representation, mainly composed of insulation layer, conductive layer and connecting layer three parts, including drawing, copper coating, etching, thickness and thin layer test, copper foil test, etc.

2. Chip circuit board processing: Chip circuit board refers to the electronic components directly pasted to the roadbed board, mainly including the chip process, welding process and cleaning process, to ensure insulation between the layers, the circuit is not short circuit.

3. Whole board assembly: Whole board assembly is to assemble the processed circuit board, including independent component assembly, embedded component installation, welding assembly, heat sealing assembly and other processes, and finally complete the assembly of the whole PCBA.

Ii. Quality control of PCBA processing plant

The quality control of PCBA processing plant is ensured by inspection and experiment. The main technical indicators include working voltage range, thermal resistance, impedance test, electromagnetic compatibility and other technical performance test.

Iii. Main equipment of PCBA processing plant

The main equipment of PCBA processing plant is SMT SMT machine, printing machine, laser etching machine, X-ray detection machine, flying tin machine, flying drawing machine, cleaning machine, wave welding machine and so on.

To sum up, PCBA processing plant refers to the production of printed circuit board, chip circuit board, whole board assembly and all kinds of electronic components processing and assembly factory, its processing process generally includes printed circuit board processing, chip circuit board processing and whole board assembly, and has strict quality control requirements, the main equipment is SMT SMT machine, printing press, laser etching machine, etc. The technology and equipment of PCBA processing plant are relatively complex, which can meet the processing and assembly requirements of various electronic components.

2. What are the characteristics of PCBA assembly plants?

As more and more products are diverted to the electronics manufacturing industry, the importance of the PCBA assembly plant is becoming increasingly prominent. PCBA assembly plant is usually a printed circuit board assembly plant, which is usually responsible for the design, manufacture, testing and installation of printed circuit boards to ensure the successful completion of electronic products. So what are the characteristics of PCBA assembly plants?

1. Design capability of PCBA assembly plant

PCBA assembly plants not only need to have high quality PCBA components, but also need to have a high level of manufacturing technology and design capabilities. A professional PCBA assembly plant generally requires a team of professionals with decades of PCBA experience and board level design capabilities such as SPC, PDCA, SMT, AI and PAD. They have the technical experience to satisfy customers, to provide customers with quality assurance, and to effectively ensure customer product performance.

Ii. Quality control of PCBA assembly plant

The quality control system of PCBA assembly plant generally includes SQC (quality assurance), IPC (industry standard), ISO (ISO Quality Management system), ESD (electrostatic discharge), ROHS (limit the use of hazardous substances), UL (American Safety certification) and a series of quality standards, which can effectively control the quality of PCBA products. Ensure the reliability of PCBA products.

Iii. Technical support of PCBA assembly plant

PCBA assembly plants usually provide comprehensive technical support, including comprehensive design consulting services, as well as technical training and support services to help customers better understand the technology and process of PCBA assembly plants, better develop their own products, effectively reduce product development costs and improve product quality.

summarize

As can be seen from the above, design ability, quality control and technical support of PCBA assembly plant are key factors to ensure product quality. It is with these excellent assembly facilities, raw materials and advanced manufacturing technology that PCBA assembly plant has the ability to achieve customer satisfaction and ultimately ensure product quality.