PCBA processing plant is a kind of fast and accurate completion of the assigned task of high performance manufacturers. It consists of three steps such as circuit board manufacturing and component mounting, which can help customers quickly realize technical product development to meet customer needs to the maximum extent. This paper will combine the development trend of new technology, starting from the three steps of PCBA processing plant, to deeply discuss how the PCBA processing plant is to complete the task quickly and accurately.

One, circuit board production

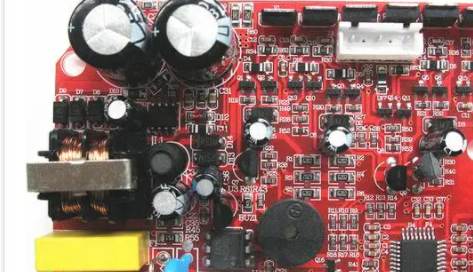

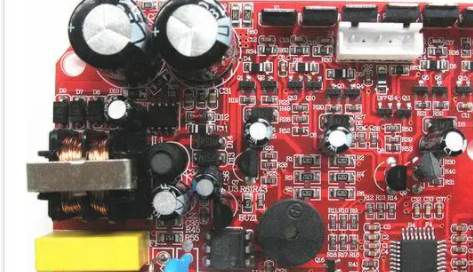

Circuit board fabrication is one of the most important steps for PCBA processing plant to complete the task quickly and accurately. It includes: plate process design, tooling design and production, circuit board production.

1. Sheet process design: sheet process design should be combined with customer requirements to accurately determine the size, shape, thickness of the circuit board, as well as the location of the required components, contacts and other information, to ensure the accuracy of the final product.

2. Tooling design and production: Tooling design and production refers to providing customers with customized tooling suitable for the size and shape of the circuit board according to the process design of the board and customer requirements, so as to facilitate the rapid and accurate processing of the final product.

3. Circuit board production: With the aid of tooling, the use of the latest equipment and technology, as well as high-precision process tools to precisely install components on the circuit board, so as to complete the production of the circuit board.

Two, component mounting

Component mounting is another important step for PCBA processing plant to complete the task quickly and accurately. It includes: manual installation, automatic installation, semi-automatic installation.

1. Manual mounting: PCBA processing plant uses professional tools and technicians to place components on the circuit board through special packaging to achieve the functional requirements of the final circuit board.

2. Automatic mounting: PCBA processing plant adopts robot system and automatic equipment to mount components on the circuit board to meet the requirements of speed and precision.

3. Semi-automatic mounting: PCBA processing plant adopts automatic mounting equipment to mount components on the circuit board under the control of processing personnel or robots, which can achieve higher efficiency and accuracy.

Iii. Testing

Testing is the final step for the PCBA processing plant to complete the task quickly and accurately. It includes: heat test, connection test and function test.

1. Thermal test: Test the temperature rise of the chip through the thermal adsorption system to ensure the performance and reliability of the product.

2. Connection test: To ensure the correct installation of the components on the PCB board and the correct connection between the circuit board, components and the schematic issued by the customer.

3. Functional testing: to ensure that products have correct functions under various normal conditions and ensure the success rate of PCB processing.

Summary: According to the above analysis, PCBA processing plant completes the rapid and accurate production of circuit board through three steps, including circuit board manufacture, component mounting and testing, so as to meet the requirements of customers on product performance and quality.

2. Three knowledge points of selecting PCBA processing plant

In recent years, the rapid development of technology makes PCBA processing plant become more and more attention. The choice of PCBA processing plant greatly affects the quality of PCBA, so it is particularly key to choose a better PCBA processing plant. The following will introduce three knowledge points in the selection of PCBA processing plant: equipment and facilities, technical personnel and service quality.

First, equipment and facilities

In the selection of PCBA processing plant, special attention should be paid to equipment and facilities, because equipment and facilities determine the efficiency and processing quality of PCBA processing plant. First of all, PCBA processing plant should have professional PCBA equipment, which can ensure the processing accuracy and quality of PCBA. Secondly, most PCBA processing plants have advanced assembly tracking system, which can effectively detect and ensure the quality of products. Thirdly, PCBA processing plant has new facilities for material inspection and scrap, which can carry out real-time material inspection to ensure the correctness of material inspection.

Two, technical personnel

PCBA processing plant has experienced, professional technical personnel is an important factor to ensure the quality of PCBA processing. The PCBA processing plant shall have the emergency capacity to deal with all kinds of problems in a short time; Have core technical ability, can provide professional technical support; And can continue to improve the quality of technology and service to meet customer needs.

Third, service quality

The service quality of PCBA processing plant is also an important consideration. Manufacturers with good service quality can respond to various requirements of customers more quickly, such as design technology and order service. In addition, PCBA processing plant can also provide a variety of services to assist customers to complete PCBA processing, such as technical support, material inspection, product assembly and other services.

In short, if you want to choose a better PCBA processing plant, you need to pay attention to equipment, facilities, technical personnel and service quality. Equipment and facilities should have professional PCBA equipment, assembly tracking system, material inspection and scrap facilities; Technical personnel should have emergency response capabilities, core technical capabilities, and continuous technical and service enhancement capabilities; Service quality requires good service quality PCBA processing plant and various services. Only comprehensive consideration of these aspects of content, can choose a to meet the requirements.