Nowadays, in Shenzhen, there are many patch processing manufacturers, these manufacturers are uneven in quality, the price is not the same, so before production, must choose a suitable patch processing plant. So, Shenzhen patch processing which is good? The following patch manufacturer to explain how to choose SMT patch processing, how to improve the quality of SMT patch processing knowledge.

1. How to improve the quality of SMT patch processing

As we all know, in the electronics industry, SMT SMT technology is very important, especially the level of its technology determines the molding effect of the product and the reputation of the enterprise, so the choice of high-quality SMT manufacturers cooperation has become the goal of electronic enterprises. As SMT patch manufacturers, in order to meet the needs of electronic enterprises, we must constantly improve the quality of the patch. So, how to improve the SMT patch processing quality?

First, select technical personnel

Most SMT patch manufacturers have their own R&D teams. They will develop various SMT patch technologies and products suitable for the development of the electronic industry according to the needs of the market and customers. Meanwhile, in order to ensure the quality of products, they will continue to introduce some testing technologies, equipment and means to ensure the final effect of products. Therefore, when choosing SMT manufacturers, kingford advises electronics companies not to forget to look at this aspect. For SMT patch manufacturers, to improve the quality of patch products, it is best to choose high-tech personnel.

2, ensure the accuracy of the equipment

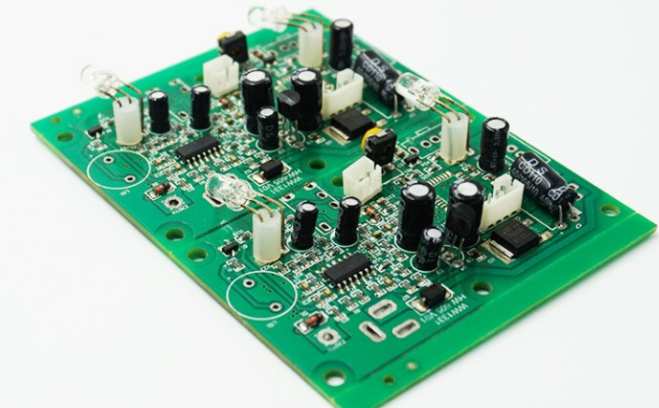

Whether testing or maintenance of products need necessary equipment, these equipment are professional equipment, the more accurate the effect is better, so, remind enterprises, when buying testing equipment, must buy high quality instruments and equipment. Although the cost of such equipment is high, the return is also very high, very cost-effective. In addition, the reliability of instruments and equipment also determines the level of product inspection and measurement results. Generally speaking, high quality instrument products have a higher success rate.

3. Set up quality detection control points

In order to improve SMT patch processing quality, it is suggested to strengthen the quality inspection of each process. Especially in the running process, must always monitor. In addition, it is suggested to add quality control points in the process, so that quality problems in different processes can be found in time, and corrected, to prevent bad products into the next process.

4, improve the management system

In addition to equipment problems, personnel operations are also prone to problems. And this requires the intervention of management system. In personnel management, must not relax, the best reward and punishment, so the effect will be better.

5. Formulate rules and regulations

There are no rules and regulations. If an enterprise wants to develop for a long time, it must have rules and regulations. Professional staff of Kunshan smt believe that good rules and regulations can restrain the loss caused by human and avoid the loss caused by personnel operation error. In addition, substandard products should be promptly dealt with and investigated for personal responsibility. This makes it easier to keep staff on their toes. How to improve the quality of SMT patches? The above is the answer given by Kunshan smt professionals. I don't know if you read it, whether to help yourself? If you want to know more, it is recommended to consult SMT patch manufacturers directly to get more professional and detailed answer information.

2. How to choose SMT patch processing

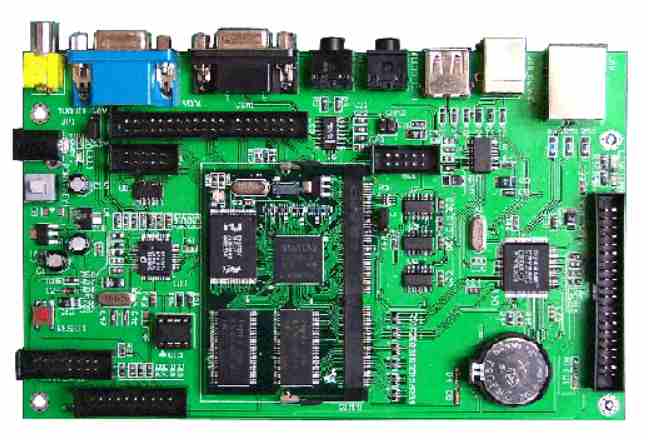

First, professional fit high patch processing is the most important link in the whole process of electronic production. The higher the professional fit of the patch processing plant, the better the quality of PCB board and the faster the production speed. Therefore, we must choose the professional fit high Shenzhen patch processing manufacturers. So, how to choose? Through talking with the management or boss of the patch processing plant, observe their attitude and philosophy of doing things, or learn about the reputation and service of the patch processing factory through the third party.

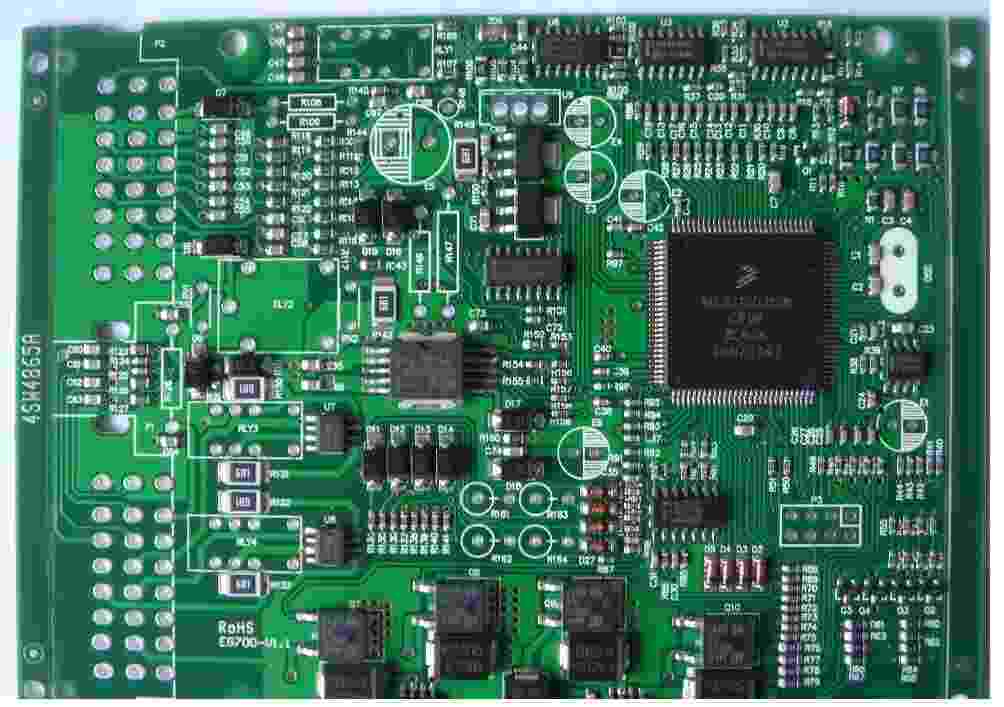

At present, in order to reduce the price to attract customers, many patch manufacturers do not hesitate to do something about quality, reduce QC personnel or do not equip with AOI testing and other means. In this way, even if the price is reduced, but the quality is not good, it will also affect the future use. Therefore, when evaluating patch processing manufacturers, it is necessary to observe whether there are QC personnel or other testing means in their warehouses, and whether engineering personnel have sorted out quality detection management methods and files. Only after a comprehensive understanding can we ensure the final quality.

Although the employee style is only a part of the reference, it can also explain certain problems. For example, in a patch processing factory, see the employees are negative, sad face, such manufacturers produced products quality rate is certainly not high, and if the employees are very good every day, the work is meticulous, the quality of the products produced by such manufacturers has a great guarantee.

When choosing Shenzhen patch processing manufacturers, some people will have their own judgment criteria and factors, such as factory size, SMT equipment, quotation, service, etc., which are indeed good measurement factors. However, Xiaobian to remind you that these factors can be referred to, but not absolute.

For example, the scale of the factory, small-scale Shenzhen patch processing manufacturers may not be able to produce your products, large-scale manufacturers may not be able to complete the order in time. Take a look at the price, because the price is high to PASS off the manufacturer's practice is very irrational. You know, although the offer is not unique standard, but there is a certain amount of truth. After all, it is impossible for manufacturers to lower prices without guaranteeing costs. In general, good patch processing manufacturers have a relatively fixed source of customers, do not need to constantly look for, only poor companies will constantly look for customers. When you cannot judge whether this company is suitable, you can know whether it is a high-quality Shenzhen patch processing manufacturer by knowing how many old customers his family has and how often they cooperate with him on average.