1. How do I select a pcb manufacturer

Nowadays, people's life is increasingly inseparable from electronic products, which also makes China's electronic industry has been growing continuously, and the integrated circuit industry has developed rapidly. The demand for pcb circuit boards is only increasing, the market demand is large, PCB manufacturers also emerge in endlessly... Nowadays, people's life is increasingly inseparable from electronic products, which also makes China's electronic industry has been growing continuously, and the integrated circuit industry has developed rapidly. The demand for pcb circuit boards is only increasing, the market demand is large, circuit board manufacturers also emerge in endlessly, for buyers, there are more opportunities to choose, but from this, in the many manufacturers, how to choose a high-quality circuit board manufacturers, has become a headache. kingford focuses on pcb circuit board, smt processing and production, has rich experience, the following will teach you how to choose high-quality pcb circuit board manufacturers:

First, look at the product

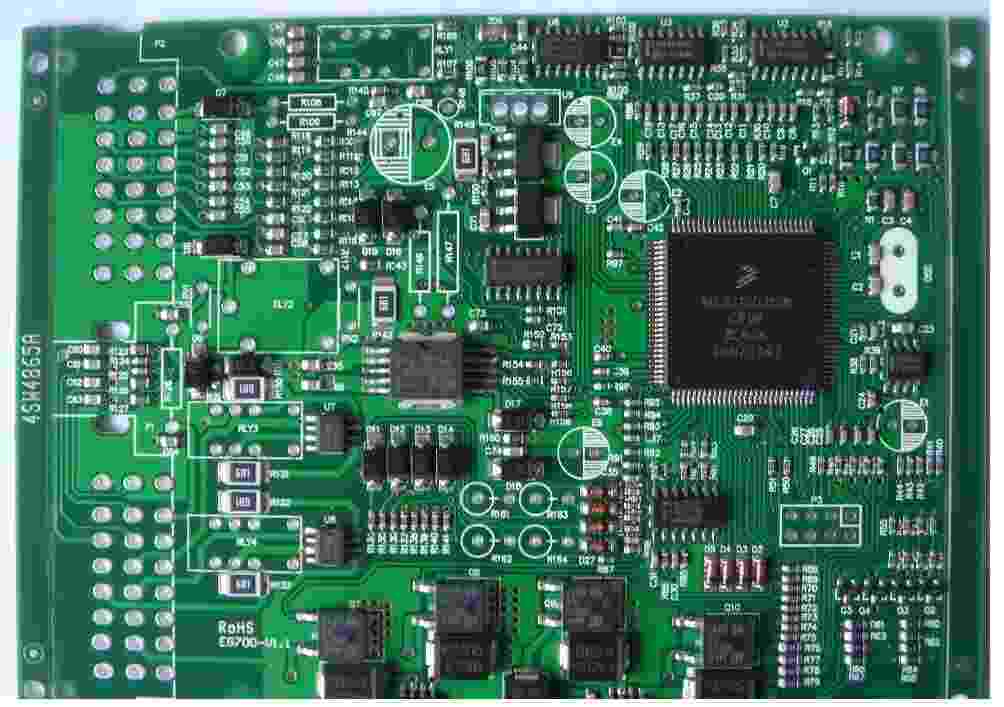

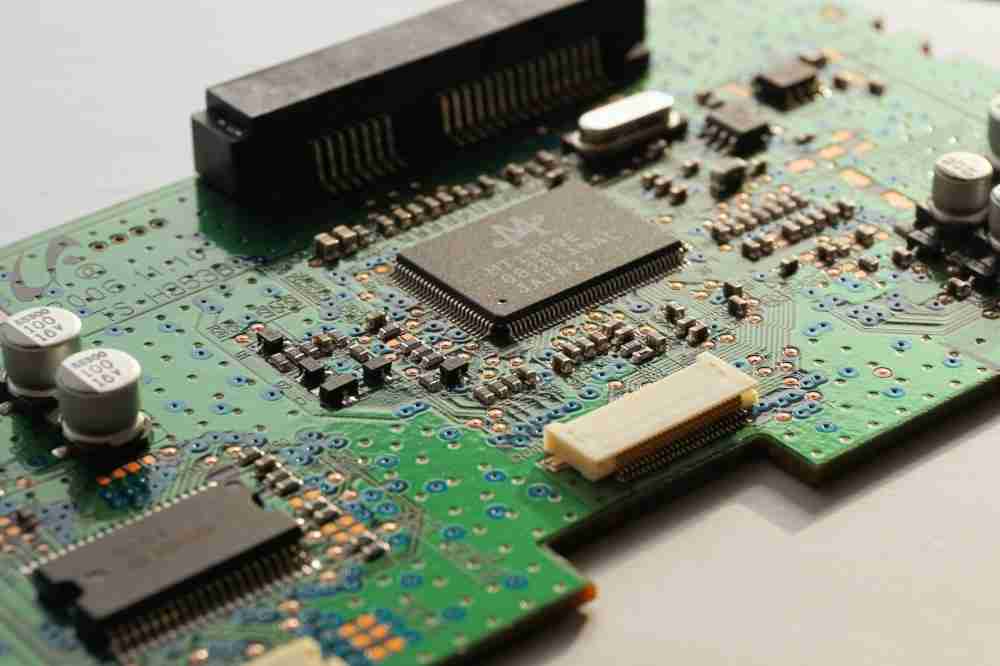

There are many kinds of pcb circuit boards, in the process and production research and development, all need to a variety of high-end technical support. In order to know whether the products produced by the manufacturer meet our procurement needs, we can first ask the manufacturer to provide some samples of pcb circuit boards. We can judge the strength and professionalism of the manufacturer by the quality of these samples. kingford provides pcb circuit board proofing, and the sample can be completed on the same day at the soonest. Two, look at the application

pcb circuit board can be used in all walks of life, a high quality circuit board manufacturer, the production of circuit board products should not be single, it should be able to provide different products for different industries demand. Shenzhen Jingbang Technology has independent production and research capabilities, with professional engineers and advanced production process, can provide customers with PCB solutions in different industries, products can be used in military research, power electronics, industrial production, communications, medical, security, automotive and other industries, involving a wide range of fields.

3, listen to the sound

The voice of customer feedback will more truly reflect the strength of the manufacturer, service and other aspects. Therefore, before determining whether to choose this circuit board manufacturer, you can search the information of relevant enterprises on the Internet to see whether there is bad negative information. If there is, you need to choose carefully. With more than ten production and research and development experience, Jingbang Technology has established a flexible system platform that ADAPTS to the design, production and service of multi-variety and small-batch products, and has established a good cooperative relationship with nearly ten thousand customers in more than 30 countries around the world, which has been unanimously praised.

4, look at the reputation

The reputation of pcb circuit board manufacturers can be reflected in many aspects, such as the business license of enterprises, certificates of honor, cooperative customers, etc., from the perspective of various factors. In addition, we can also know whether the manufacturer has a good reputation and whether it can do what it says through its commitment to customers. Jingbang Technology is a private technology enterprise recognized by Shenzhen Science and Technology Bureau. It is an excellent supplier recognized by many well-known enterprises at home and abroad. With high reputation, it can promise fast delivery within 3 days and guarantee quality and quantity.

5, look at the service

Good pcb manufacturers, of course, need to have good service. The purchase of pcb circuit board needs to involve many issues, such as product process, product use, product warranty, etc., need to have a perfect service system. And the pre-sale service we can communicate with the manufacturer to see whether we can give customers detailed product introduction, whether we can be patient and quickly solve customer problems. After-sales service is to see whether the manufacturer can provide package return, warranty, technical guidance and other problems that may be encountered in the later period.

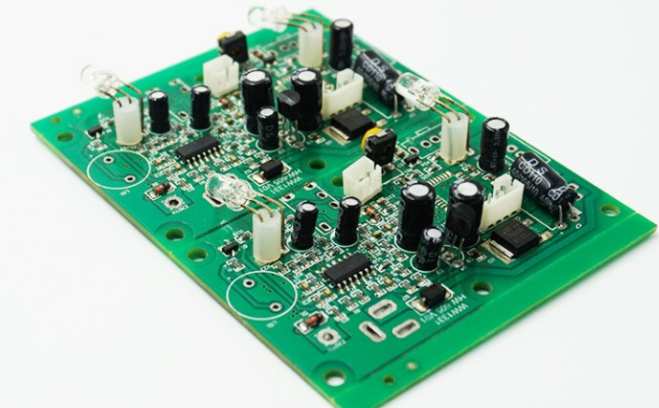

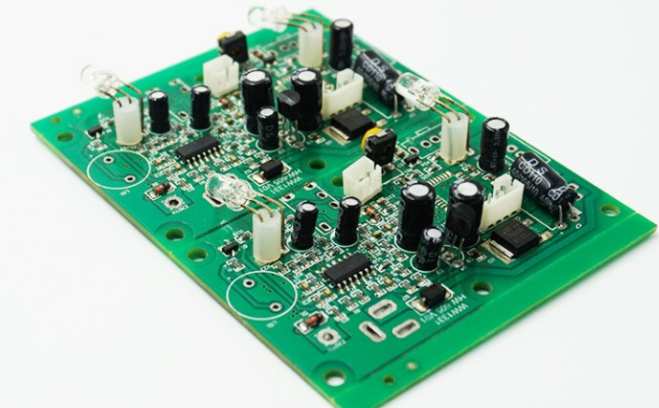

2. How to improve smt patch processing quality

First: the enterprise to establish a total quality (TQC) organization network, quality feedback timely, accurate selection of the best quality personnel as the quality inspector of the production line, and the administration is still under the quality department management, so as to avoid other factors to the quality of the work of interference.

Second, experts from Shenzhen SMT processingservice providers say that in order to ensure the accurate product inspection and maintenance of testing and maintenance equipment, the inspection and maintenance are carried out through the necessary equipment and instruments, such as multimeters, anti-static wrists, soldering iron, ICT and so on. Therefore, the quality of the instrument itself will directly affect the quality of production. In accordance with the provisions of timely inspection and measurement, to ensure the reliability of the instrument.

Third: It is unrealistic to set the quality process control point to achieve "zero defect" production, but the implementation of "zero defect" production goal in the whole factory can greatly improve the quality awareness of the whole factory staff, and provide continuous power for timely and standardized solution of quality anomalies in production.

Fourth: the quality department shall formulate necessary rules and regulations related to quality and the work responsibility system of the department to restrict the avoidable quality accidents by laws and regulations, reward and punishment are clear, participate in the quality assessment by economic means, and set up monthly quality awards within the enterprise.