After reflow welding or wave soldering, PCB board may appear bending and warping deformation problems, if serious, even burst stratification problems. However, problems such as burst stratification are rare, while deformation problems such as bending and warping are more common, and often lead to abnormalities such as air welding, virtual welding, stellation and deviation. Then, how to judge whether PCB board is deformed? What are the hazards of PCB board deformation?

The criterion, cause and measurement method of PCB board deformation

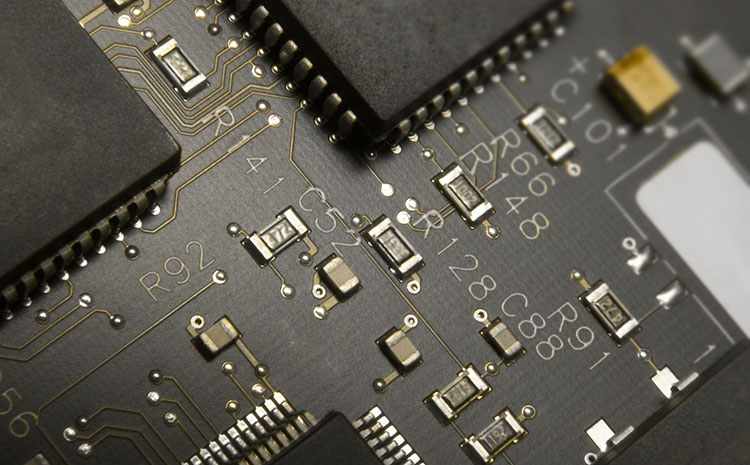

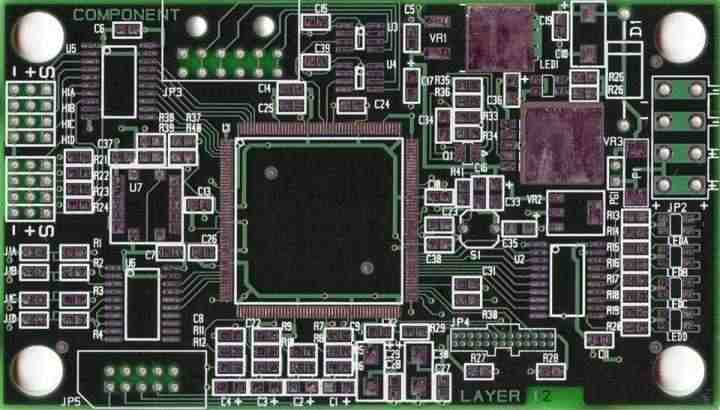

The industry usually uses the flatness to measure the deformation of printed circuit board, and the flatness is mainly determined by two characteristics, namely: bow bend and distortion. Bow bend refers to that when the four corners of the PCB board are in the same plane, it is roughly into a cylindrical or spherical bending condition, and the distortion refers to that one corner of the PCB board is not in the same plane with the other three corners, and parallel to the board diagonal, warped. If the PCB board is round or oval, it must be measured against the highest point in the vertical displacement direction. The flatness of PCB board may be affected by board design. Because different wiring or multilayer structure will lead to different stress or stress relief conditions. The thickness and material characteristics of PCB board are also important factors affecting smoothness.

For example, in the selection of copper coating, large PCB circuit board, if the design is all copper, then when the PCB physical board is subjected to external force, will maintain the warping condition, but if the design is grid, it will not maintain, and will return to the original flat condition, under normal circumstances, the design, the process side also left copper, The purpose is to ensure the smoothness of the PCB board.

According to IPC standards, if PCB board needs to be printed, the deformation amplitude should be less than 0.75%, if PCB board only needs plug-in, the deformation amplitude should be less than 1.5%. (Note: in IPC standard, called warp degree)

So, if in accordance with IPC standards, how to measure and judge whether the PCB board deformation is qualified? First of all, put the PCB board on the marble platform or glass plate larger than 5cm thick, use the plug gauge to measure the maximum corner size, then, use a ruler to measure the length of the PCB diagonal, if the drop /2 times the value of the diagonal > 0.75%, it is not qualified (note: only plug-in, then widen to 1.5%).

PCB board deformation harm

If the circuit board is uneven on the automatic surface mounting or cartridge line, it may cause inaccurate positioning, fail to mount or insert components on the board, or even cause device failure or damage. However, if the welded PCB board is deformed, it is difficult to cut the foot of the plug-in flat, which increases the working difficulty of tin handling and other processes. In addition, there will be a lot of abnormal air welding, virtual welding and so on accompanied by the patch, which greatly increases the workload of the subsequent board repair. Finally, in the process of assembly, deformed PCB board may bring serious troubles to the production. For example, PCB board does not fit well with the shell, and the efficiency of some PCB board during assembly may only be one tenth of that of other boards, and the probability of subsequent defects increases several times, which further aggravates the after-sales problems. Therefore, with the development of the industry, PCB board deformation problem, more and more attention, and continue to put forward higher requirements. Some customers with high requirements for product reliability have begun to develop their own more stringent standards on the basis of IPC's standards, in order to ensure that their products are more competitive.

But PCB board is composed of copper foil, resin, glass fiber cloth and other materials, there are differences between the physical and chemical properties of various materials, in the process of processing, will go through chemical drops, cold and hot changes, deformation is inevitable. The improvement of deformation is an industrial problem that cannot be solved overnight, but it can be improved step by step.