Machine Vision System for SMT Machining

Machine vision systems are the second factor that significantly affects component assembly. The machine needs to know the exact position of the printed circuit board and determine the relative position of the components and the circuit board to ensure the accuracy of automatic assembly. Imaging is done using a visual system. Depending on the location or type of camera, the vision system is usually divided into top view, bottom view, head or laser alignment.

(1) The overhead monitor searches for objects on the circuit board so that the circuit board can be placed in the correct position before assembly.

(2) Heads up cameras are used to detect elements at fixed positions, usually using CCD technology. Before assembly, the parts must be moved above the camera for visual processing. At first glance, this may seem a bit time-consuming, but since the placement head must be moved to the feeder to pick up the components, if the camera is set between the pick position and the installation position, video acquisition and processing can be carried out in the process of moving the placement head at the same time to shorten the placement time.

(3) The head camera is directly mounted on the placement head. In general, linear sensing technology is used to complete the detection of components in the process of picking them to the specified position. This technology is also called "flight centering technology". The installation efficiency can be greatly improved.

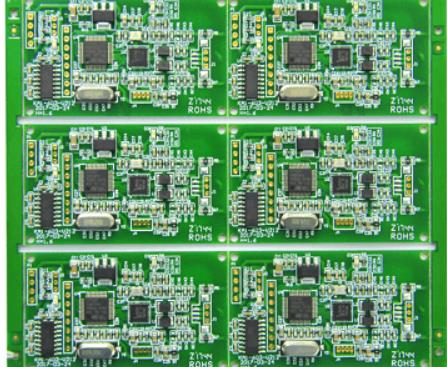

Circuit board

(4) Laser alignment refers to generating medium beam from the light source and illuminating on the component to measure the size and shape of the component and the deviation of the central axis of the nozzle. However, for components with pins, such as SOIC, QFP and BGA, a 3D camera is required for detection. In addition, the alignment of each component requires more seconds. Obviously, this will have a great impact on the speed of the whole mounter system.

Among the three component alignment methods, CCD technology is the best. At present, the efficiency of CCD hardware has reached a considerable level. The development of "backlight" and "reflected light" technology and programmable lighting control technology can better meet the needs of various component placement.

Surface mount component treatment

2. Feeding

The boom type machine can support many different types of feeders, such as belt type, disk type, bulk type, tubular type, etc. This is in contrast to the high-speed installation system, which can only use bulk or ribbon feeders. When installing mainframe (IC, such as QFP and BGA), boom machine is the only choice.

3. Flexibility

Flexibility is a key factor to consider when selecting SMT placement equipment Due to the increasingly fierce competition of electronic products and the increasing uncertainty in production, product output is often adjusted or product transformation is arranged Therefore, the corresponding requirements are put forward for the placement machine, that is, the system is required to have good flexibility Adapting to the current changing manufacturing environment is what we usually call flexible manufacturing system For example, for some brand mounters, when the functions from distribution to placement are exchanged, only the distribution components and placement components need to be replaced The equipment is suitable for multi - task, multi - purpose and short - term production cycle Processing enterprises

In short, the following key issues must be considered when selecting equipment: machine type, imaging, feeding, and flexibility. With this understanding, you can identify the advantages and disadvantages of different devices and make wise choices. At the same time, when selecting equipment, we should be based on actual needs, and we must not blindly pursue major events to avoid unnecessary waste.

The above is the explanation given by the editor of pcb circuit board company.

If you want to know more about PCBA, you can go to our company's home page to learn about it.

In addition, our company also sells various circuit boards,

High frequency circuit board and SMT chip are waiting for your presence again.