How to prevent incorrect data in PCBA manufacturing?

PCBA manufacturing technology This equipment belongs to the high price fast automation equipment PCBA manufacturing workshop As long as production starts, the production department can complete the order task in a short time However, there is also a risk that PCBA manufacturing technicians have installed the wrong data tray If there is an error, the output of the entire manual is ng product, which will be manufactured for PCBA Therefore, at present, PCBA manufacturing technology workshop will organize a large number of resources to carefully check the bill of materials before starting production. PCBA manufacturing machines will start production to ensure that everything is normal, and start production after achieving a stable production effect At present, however, most PCBA manufacturing machines rely on manual loading inspection and verification The main sources of PCBA manufacturing errors are as follows:

(1) The material identification of the material tray is incorrect, and the material name does not correspond to the physical object;

(2) The material preparation quantity of the coiler is wrong, especially the quantity is insufficient;

(3) The feeder number corresponds to the material reel one by one, and is copied manually, possibly copying the wrong data;

(4) When the feeder is pushed into the PCBA manufacturing machine after loading, the placing sequence is wrong.

(5) The root cause is that manual operation inevitably leads to omission at any time,

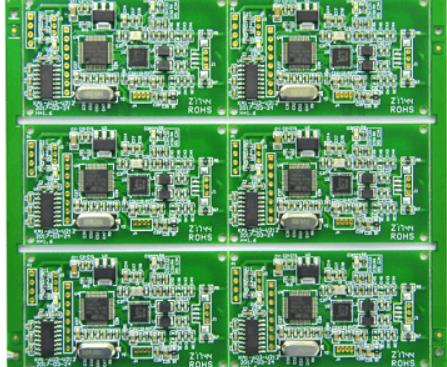

PCBA manufacturing

PCBA manufacturers use the error proofing system with PDA manufactured by PCBA to automatically check whether the data is wrong and minimize the occurrence of error data, so as to solve the error prone PCBA manufacturing technology during manual data calibration

The method to realize error proofing: combining hardware and software, using barcode technology, the system automatically matches whether the project BOM, station list and materials used in actual operation are correct.

The key steps for PCBA manufacturers to achieve error proofing are as follows:

1. The scientific and technological operator of PCBA manufacturing machine can import the position table of the placement machine with one key in the system, and automatically compare the system BOM, so as to effectively prevent the error of the position table.

2. When the production line employees of PCBA manufacturing technology workshop load and receive materials, scan the station number on the machine with a scanning gun, and then scan the barcode labels on the materials. The machine system of PCBA manufacturing technology equipment will automatically check whether the loading is correct. If an error occurs, the PCBA manufacturing machine system will automatically alarm and lock the line. The alarm can be released only after IPQC confirms the reason and inputs the password, and the employee receives the data without permission, alarms and stops the production line.

3. The station scanned and confirmed by the production line of PCBA manufacturing technology workshop will prompt the measured value on the IPQC computer. IPQC transmits the measured value data to the system through the bridge, and the PCBA manufacturing machine system will automatically determine the measured value results.

4. The PCBA manufacturing technology workshop group can start production only after all the measured values of IPQC for the first feeding pass

The above is the explanation given by the editor of pcb circuit board company.

If you want to know more about PCBA, you can go to our company's home page to learn about it.

In addition, our company also sells various circuit boards,

High frequency circuit board and SMT chip are waiting for your presence again.