How does the etcher PCB work?

Double sided etching machine production line:

1. Features of the production line:

1. This machine adopts PLC automatic control system, human-machine interface control, imported electrical components, simple and convenient operation.

2 Special nozzle layout PCB design, independent nozzle pressure adjustment display screen, driving distance of 5cm, making the spray more uniform and faster

3. The liquid tank is separated from the body, so that the body and the spray system are not easy to deform at high temperature.

4. The wheelbase can be adjusted from 23mm to 50mm, and soft and hard boards can be processed.

5. It integrates the design of exhaust, drainage, water supply and drainage, with clean appearance and convenient installation.

6. The etching accuracy can reach line width and line spacing of 4m.

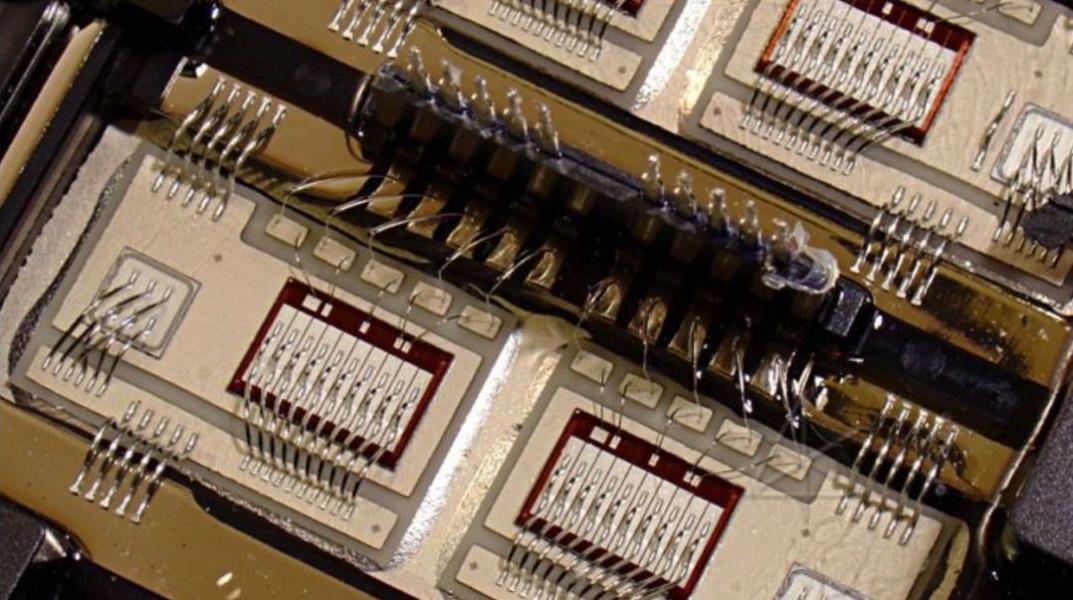

2. PCB process flow

Loading - etching - ammonia flushing - pump flushing I - pump flushing II urban water flushing - drainage - unloading

Antioxidant production line:

1. Production line use

The stable conveying system and loop filtering system of the production line form a uniform and firm organic protective film on the workpiece surface (copper surface), which makes the plate surface have excellent oxidation resistance and good weldability. This production line is applicable to all kinds of syrup formulations at home and abroad, and is an ideal equipment for PCB double-sided multilayer board manufacturing technology.

Second, process flow

Plate feeding - degreasing - cycle water cleaning - micro etching - cycle water cleaning - pickling - cycle water cleaning - Dl water spraying - blotting paper - wind cutting - oxidation resistance - blotting paper - wind cutting - cycle water cleaning - Dl water spraying - drying - drying - far infrared drying - plate discharging

Circuit board

3. Features

1. Advanced process structure design and soft transfer roller are adopted to avoid scratches on the workpiece surface.

2. Small wheelbase, double drive system, thin plate and small plate (40 * 60mm) can pass smoothly.

3. The continuous filtration system stabilizes the solution.

4. Advanced water loop system and PLC control system can save energy and reduce production costs.

5. The integrated drainage and exhaust system and transparent tempered glass windows make the machine beautiful and generous.

Demembrane cleaning production line:

1. Features of the production line:

1. In SUS high-temperature immersion area, stainless steel pump completely separates the membrane from the plate surface.

2. The convenient and fast slag removal and filtering system can fully filter the residue in the solution, making the membrane removal effect better.

3. Soft scrubbing makes the board surface cleaner.

4. The reasonable piping design reduces the water and electricity loss and effectively reduces the production cost.

5. Comprehensive ventilation and drainage design, overhead wiring, more beautiful appearance, cleaner environment.

2、 PCB device process

Plate installation - soaking - stripping - brushing - loop water flushing 1, 2 - municipal water flushing - blotting paper - plate removal

The above is the explanation given by the editor of pcb circuit board company.

If you want to know more about PCBA, you can go to our company's home page to learn about it.

In addition, our company also sells various circuit boards,

High frequency circuit board and SMT chip are waiting for your presence again.