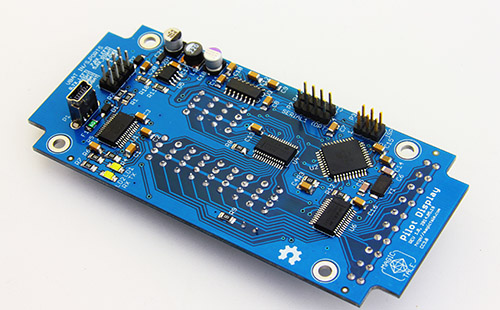

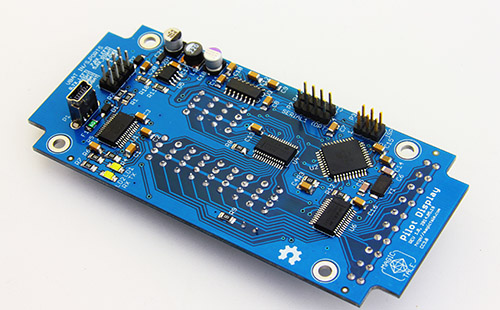

PCB printing technology is moving towards nanometer level. Have you arranged in advance?

PCB manufacturing, PCB design and PCBA processing manufacturers explain that PCB printing technology is moving towards nanometer level

Nanotechnology is becoming more and more important to the future of printing and printing ink. This is not only in Europe, but also in every corner of the world.

If the printing industry wants to further expand the market and extend its tentacles to emerging fields such as electronics, it must learn to use nano particles and materials in ink.

Nanotechnology is no stranger to people. It provides the production basis for many new products. By 2015, the sales of nano products are expected to reach several trillion dollars.

Printing may also be able to get a share of this growing market, because the application cost of printing is low, and nano level inks and coatings can be used on various substrates.

At present, many materials can be used to produce nano components, such as carbon, silver, iron, titanium dioxide, aluminum oxide, cerium oxide, zinc oxide, silicon dioxide, silicon dioxide and nano clay. Although they have not been fully used in ink and coating formulations, their future development potential cannot be ignored.

In addition, if nanotechnology is to be widely used in printing and other fields, it still needs to meet many difficult challenges, among which the most difficult is to ease people's concerns about health and safety, especially in Europe, where policies and regulations are relatively strict.

Steve Hankin, senior consultant of the British Institute of Labor Health, said: 'The safety information on nanomaterials in the market is not complete, and there is a huge knowledge gap in toxicology, physicochemical properties and exposure data, which makes it difficult for people to conduct risk assessment and risk management on nanomaterials.

Therefore, many companies in Europe require their suppliers to explain the nano components in their products, especially packaging products.

In addition to safety, another headache is the increase of research and development costs of nanomaterials. This requires not only high-level R&D personnel, but also expensive equipment. In order to step up the pace of technological innovation, small enterprises need to invest a lot of money.

Paul, manager of a small British company that is developing nano inks for printing and electronics, said that nanotechnology has changed from materials that meet a single requirement to complex solutions that can meet multiple requirements.

Strict health and safety requirements and increasing research and development costs make nanotechnology a luxury, which is far beyond the limits of some ink manufacturers.

Even some large enterprises in the ink market cannot afford to set up an internal R&D team.

In addition to enterprises specializing in nanotechnology, some European universities and research institutions are also very interested in nanotechnology, and penetrate into the ink market by manufacturing ink or providing nano ingredients for ink products.

For many years, ink manufacturers have been using milling methods to produce nano pigment particles to improve the color quality and performance of ink formulations.

The use of nanotechnology in traditional coatings can make the substrate scratch resistant. Ink containing nano particles can be used in most printing processes, especially in the production of printing electronics.

At present, nanomaterials can be printed on various printing materials for the production of RFID tags, fluorescent displays, plastic cells, sensors and solar cells.

In the printing field, ink-jet ink is the most widely used nanotechnology, because it needs to add small particles in the formula, especially for dyes and pigment inks.

The development of ink-jet technology and nano materials complement each other. With the maturity of ink-jet printing technology, nanomaterials have also made exciting progress.

For example, nano micron materials used in ink-jet printing can also be used in the production of photochromic or electrochromic inks, antibacterial agents, flame retardants, conductive graphite and metals, magnetic materials, enzymes and other biological materials.

Nanomaterials in traditional and ink-jet inks are mostly used in security, brand protection, anti-counterfeiting and other fields, which is also one of the largest markets for nanotechnology in the printing industry.

Under the current market conditions, printing nanotechnology suppliers and developers should pay close attention to the regulatory authorities in Europe and other countries, and understand the overall development level of this technology, so as to find the best development direction.

PCB manufacturers, PCB designers and PCBA manufacturers will explain that PCB printing technology is moving towards nanometer level.