What is the SMT red glue process? Under what circumstances?

PCB manufacturers, PCB designers and PCBA manufacturers explain to you what the SMT red glue process is? Under what circumstances?

SMT red glue process is an old process. With the continuous development of solder paste process, the solder paste has a good welding effect, gradually replacing the SMT red glue process as the mainstream welding process. However, in some cases, the red glue process will also be used.

1、 What is the SMT red glue process

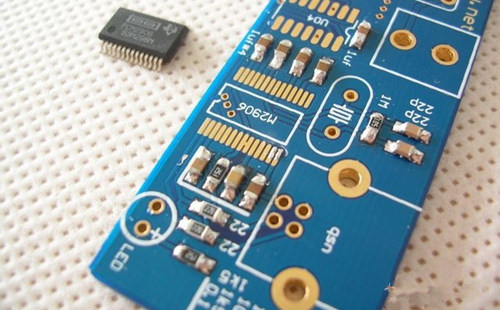

SMT red glue process is to take advantage of the heat curing characteristics of red glue, fill it in the middle of two bonding pads through a printing machine or a dispensing machine, and then complete the curing welding through the patch and reflow soldering. Finally, the surface is mounted on the side of the wave crest during the wave crest soldering, and no fixture is required to complete the welding process.

2、 When to use SMT red glue process

1. Cost savings

The SMT red glue process has the advantage that it can be used as a tool during wave soldering, which can reduce the cost of making tools. Therefore, some customers who place small batch orders, in order to save costs, often require PCBA manufacturers to adopt red glue process. As a relatively backward welding process, PCBA processing plants are generally reluctant to use the red glue process, because the red glue process can only be used under certain conditions, and the welding quality is not as good as the solder paste welding process.

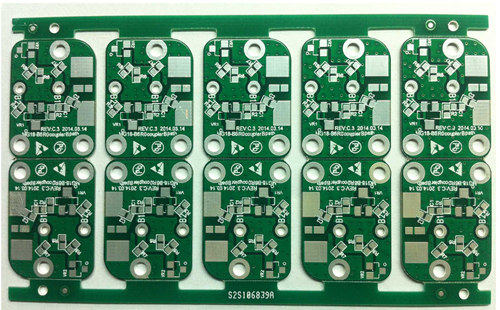

2. The components are relatively large and the spacing is wide enough

When the circuit board is soldered over the wave crest, the surface mounted side is generally selected, and the plug-in side is above. If the surface mounted components and spacing are too small, the solder paste will be connected together when tin is applied to the wave crest, causing a short circuit. Therefore, when using the red glue process, ensure that the components are large enough and the spacing is not too small.

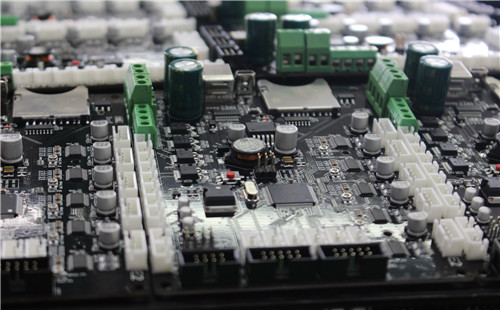

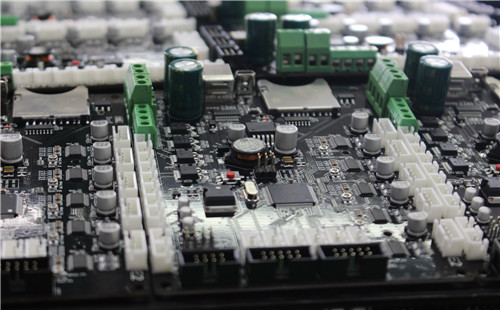

Nowadays, the mounting density of circuit boards is getting higher and higher, and the components and parts are getting smaller and smaller. In this case, the SMT red glue process is not suitable for the needs of technological development, but the low cost advantage of the SMT red glue process is still popular with some customers.

PCB manufacturers, PCB designers and PCBA manufacturers explain to you what the SMT red glue process is? Under what circumstances?