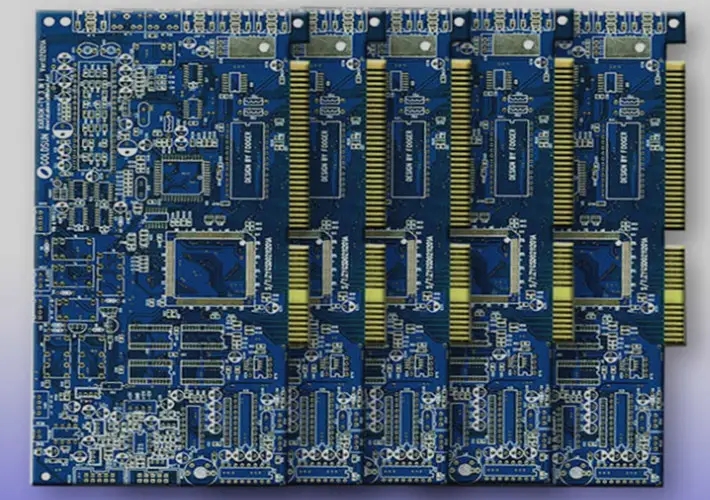

The price of PCB is composed of the following factors: 1. The materials used for PCB circuit boards are different. Take ordinary double-sided boards as an example. The board materials generally include FR-4, CEM-3, etc. The board thickness varies from 0.6 mm to 3.0 mm, and the copper thickness varies from Oz to 3 Oz. In terms of PCB solder resist ink, common thermosetting oil and photosensitive

PCB price consists of the following factors:

1、 Different materials are used for PCB

Take ordinary double-sided plate as an example. The plate materials generally include FR-4, CEM-3, etc. The plate thickness varies from 0.6mm to 3.0mm, and the copper thickness varies from ½ Oz to 3 Oz are different. In terms of solder resist ink, there is a certain price difference between common thermosetting oil and photosensitive green oil.

2、 PCB adopts different production processes

Different production processes will result in different costs. For example, gold plating plate and tin spraying plate, gongs (milling) plate and beer (punching) plate with shape, silk screen circuit and dry film circuit will all have different costs.

3、 The difficulty of PCB is different

Even if the materials are the same and the PCB process is the same, different difficulties of PCB itself will cause different costs. For example, if there are 1000 holes on both kinds of circuit boards, the drilling cost will be different if the hole diameter of one board is greater than 0.6 mm and the hole diameter of the other board is less than 0.6 mm; If the other two types of circuit boards are the same, but the line width and line spacing are different, one is greater than 0.2mm, and the other is less than 0.2mm, it will also cause different production costs. Because the boards with great difficulty have a higher scrap rate, the cost will inevitably increase.

4、 Different customer requirements will lead to different prices

The level of customer requirements will directly affect the yield of the board factory. For example, according to IPC-A-600E, a board has a 98% pass rate in class1, but only 90% pass rate in class3.

5、 Different PCB manufacturers

Even if the same PCB product is produced by different manufacturers with different process equipment and technical levels, it will also result in different costs. Nowadays, many manufacturers like to produce gold plated boards because of their simple process and low cost. However, some manufacturers produce gold plated boards, which will rise as soon as they are scrapped, resulting in higher costs. Therefore, they prefer to produce tin sprayed boards, so their quotation for tin sprayed boards is lower than that for gold plated boards.

6、 Different payment methods

At present, PCB manufacturers generally adjust PCB prices according to different payment methods, ranging from 5% to 10%.

7、 Different regions

At present, in terms of geographical location in China, prices are increasing from south to north, and there are certain differences in prices in different regions.