Teach you how to use X-Ray to check the solderability of BGA solder balls

Check the solderability of BGA solder ball welding with X-Ray

General X-ray inspection machines can only view two-dimensional (2D) images, but it is difficult to see whether there are empty solder joints or solder ball cracks in two-dimensional (2D) images, because the image can only see the shape of the whole solder ball, but if there are too many or too large bubbles in the solder ball, it is very likely to cause the problem of fracture. In addition, if the outer diameter of the solder ball is larger or smaller than other adjacent solder balls, it is also possible to cause empty solder joints, But this is just a judgment based on experience.

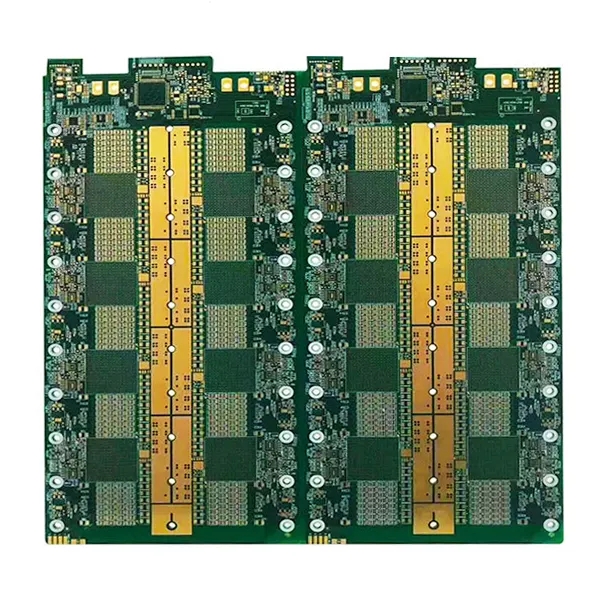

1、 BGA solder ball becomes larger, causing empty soldering

First, consider that the solder balls of the same BGA should be the same size. If some solder balls are empty and some solder balls are complete, will the shapes of the two solder balls be different? The answer is yes. Imagine that after the same volume of solder ball is compressed, a part of the tin of good solder ball will disperse to the pad of PCB, making the solder ball smaller; The solder ball with empty soldering will not, and the solder ball will become larger after being compressed.

When solder balls of the same size are empty, the diameter of the solder balls will become larger. Of course, it is better to compare whether the solder balls of normal boards are all the same size, because the design of some boards will cause the solder balls to become smaller, which will be described later.

When solder balls with the same size of BGA are empty, the diameter of solder balls will become larger

In addition, it is generally believed that the phenomenon of tin ball enlargement is highly positively related to the adverse phenomena of HIP (Head In Pillow) and NWO (Non Wet Open). However, it is difficult to detect the general HIP and NWO with two-dimensional (2D) X-Ray, because the size of its BGA sphere does not change much.

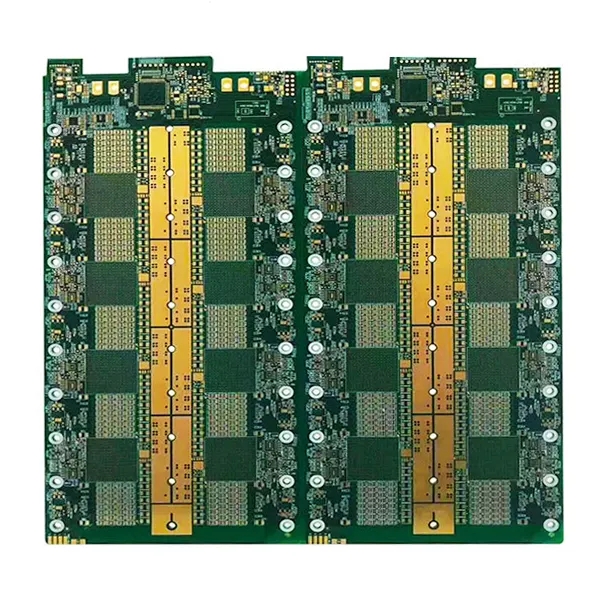

2、 Through hole (via) leads to empty solder with insufficient tin

Another empty soldering phenomenon is insufficient tin. This phenomenon usually occurs when the solder pad has a via, because when the solder ball flows through the reflow, part of the tin will flow into the via due to the wicking phenomenon, which causes insufficient tin. Sometimes the via will also cause this problem next to the solder pad. At this time, the sphere seen from the X-Ray will become smaller, and if the amount of tin is eaten too much by the through hole, the solder will be empty.

In addition, recently, there are new X-Ray inspection machines that can produce stereo image results similar to those of hospital computed tomography scanning. They can present stereo images and check whether there are defects in soldering. However, because the cost of this machine is too expensive, it is unlikely for ordinary pcb factories to purchase such equipment. A more feasible way is to rent this kind of X-Ray machine to an external laboratory for preliminary inspection. If this kind of inspection can detect the problem of BGA defect, it is unnecessary to use the subsequent destructive test.