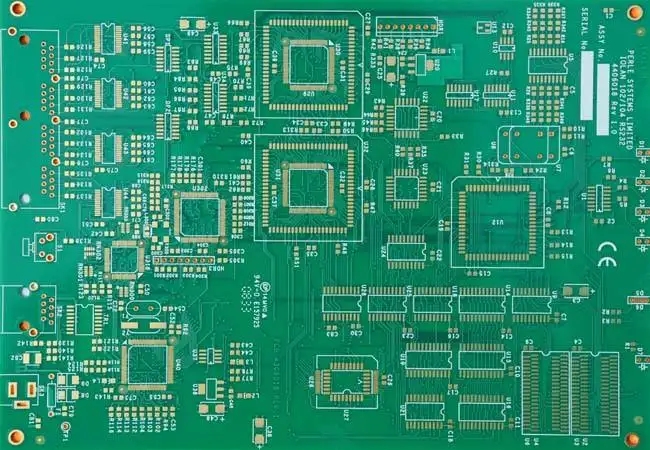

Milky white residue after circuit board welding

What is the cause of milky residue after circuit board welding

In the process of SMT chip processing, many links are involved, so the control of project production process involves many links. Therefore, some PCBA products may have milky residue after being dirty, stored, or welding failure.

In the process of SMT chip processing, many links are involved, so the control of project production process involves many links. Therefore, some PCBA products may have milky residue after being dirty, stored, or welding failure. Now let's know what this milky residue is? How did it happen?

The important components of white residue are all the turpentine oil contained in the welding fluid itself. The turpentine oil is generally a transparent and hard amorphous solid disk compound. Compared with the crystal, the amorphous compound generally stores too much mechanical kinetic energy, which is called the thermodynamic instability. Therefore, the turpentine oil tends to crystallize, leading to the crystallization of the turpentine oil. The main reasons for the change from colorless transparency to milky white powder are as follows:

1、 Structure of compounds in turpentine oil

The proportion of the isomers of the resin acid has great harm to the crystalline development trend of the turpentine oil. The important compound of milky residue caused by removing dirt is the crystalline powder caused by the volatilization of turpentine oil in the solvent.

What is the cause of milky residue after circuit board welding

2、 Moisture in turpentine oil

In addition to the reasons of turpentine oil itself, water is very harmful to the turpentine oil products. The turpentine oil itself has a certain water absorption capacity, and the resin acid can be specified on the water surface, resulting in a standard crystallization. It is generally felt that the turpentine oil with a moisture content of 0.15% or above is easy to cause crystallization. When PCB is stored under the high and low temperature test specifications, and the digested moisture exceeds a certain level, the turpentine oil will gradually change from a filamentary glass state with no color and transparency to a crystal shape, which is visually milky white powder. This is all why after the same PCB is stored, it is unnecessary to remove part of the soldering fluid and part of the tin strip for repair welding, which will cause milky white powdery residue

3、 Other reasons

When there are crystals of other compounds dissolved in the turpentine oil, and when the product development of the turpentine oil tends to expand, such compounds will become seed crystals and lead to the crystallization of the turpentine oil. This milky white powder on PCB is still turpentine oil in essence, but its appearance is different, so it still has high quality volume resistivity.