5 Keys to PCBA Processing

The human demand for electronic products continues to grow, which promotes the rapid development of the electronic manufacturing industry and the precipitation of process technology. With the popularity of smart phones and wearables, the lean manufacturing capability of electronic products is required to be higher, which inspires more electronic manufacturing enterprises to attach importance to PCBA quality management. This paper focuses on the key points of PCBA electronic manufacturing quality management.

The human demand for electronic products continues to grow, which promotes the rapid development of the electronic manufacturing industry and the precipitation of process technology. With the popularity of smart phones and wearables, the lean manufacturing capability of electronic products is required to be higher, which inspires more electronic manufacturing enterprises to attach importance to PCBA quality management. This paper focuses on the key points of PCBA electronic manufacturing quality management.

1. PCB production

There are many factors that determine PCB quality, among which substrate material, dust-free exposure and copper coating are the most critical. PCB factories should not only focus on their scale and environment, but also on these quality key points. The grading of substrate materials varies from A to C, and the price varies greatly. The purity management of the dust-free exposure workshop can also be known through the documents of the third-party testing agency. The copper coating process of PCB requires high consistency and uniformity. The management of solution replacement must be standardized, and equipment maintenance must be in place. Copper cladding process also needs to be summarized and improved repeatedly in practice.

2. Component procurement

Ensure that the components come from the original brand, which is the key to the packaging process and can eliminate batch defects from the source. Electronic manufacturing enterprises need to set up incoming quality control posts (IQC, Incoming Quality Control) to check the consistency of incoming materials and sample the appearance, component values, errors, etc. PCBA electronic manufacturing enterprises also need to constantly optimize their component supplier channels.

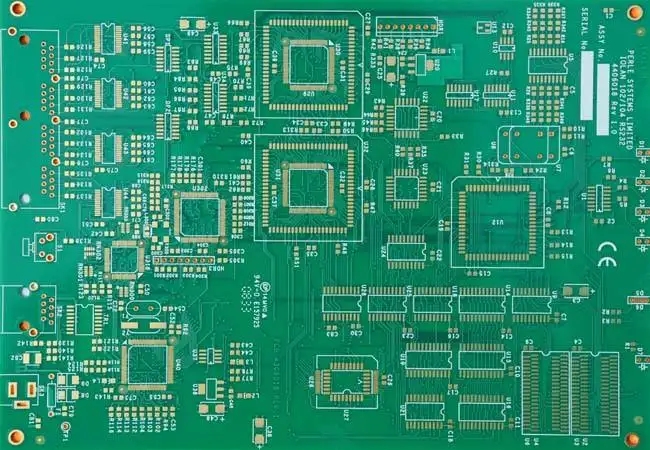

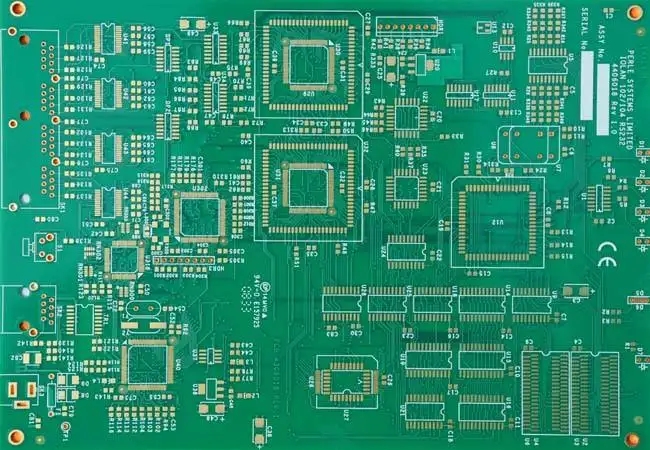

3. Surface mounting process

In SMT surface mounting process, PCBA electronic manufacturing enterprises need to ensure the uniformity and consistency of solder paste printing, the reasonable programming of SMT machines, and ensure the high precision IC and BGA mounting yield. 100% AOI inspection and in process quality control (IPQC) are necessary. At the same time, it is necessary to strengthen the material loading management. From picking to the stack table, strict document management is required.

4. PCBA test

Design engineers generally reserve test points on PCBs and provide corresponding test plans to PCBA electronic manufacturers. In ICT and FCT tests, the voltage and current curves of the circuit are analyzed, as well as the functional test results of electronic products (possibly with some test racks), and then the test schemes are compared to determine the acceptance range, which is also convenient for customers to continue to improve.

5. Management of people

For PCBA electronic manufacturing enterprises, high-end and sophisticated equipment is only a small aspect, and the most important is human management. The key is for the production management personnel to formulate a scientific production management process and supervise the implementation of each station.

In the fierce market competition, electronic manufacturing enterprises continue to optimize their internal skills and refine their production management is the key to constantly adapt to the market. Manufacturing quality control and service will become the lifeline of competition.