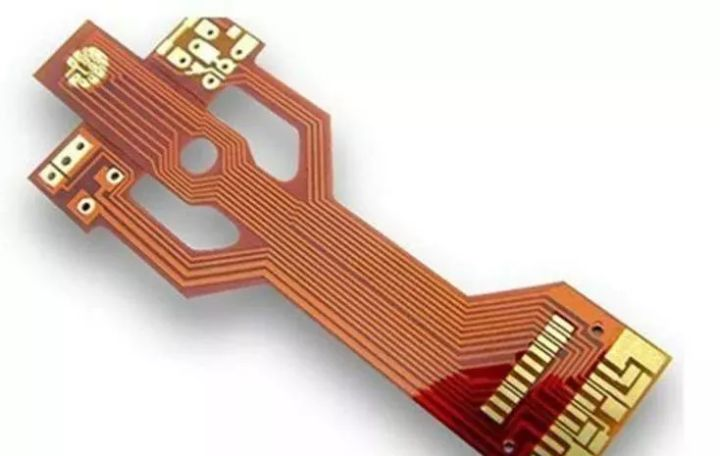

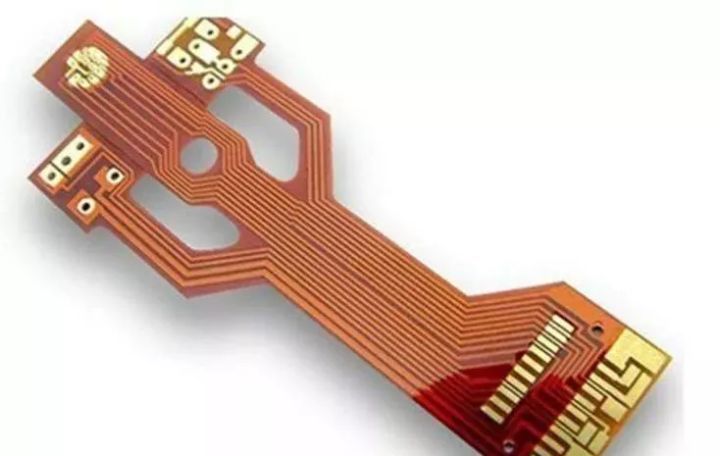

The FPC flat cable has good flexibility and good bending property, and the length can be left with allowance, so it is unnecessary to calculate it accurately. If the design is too long, it can be gradually shortened according to the analysis results after the sample is made and the folding experiment is completed. If the number of pins is too large, it is necessary to make them wider, or use double-sided boards to replace single panels to reduce the width. Of course, the thickness of FPC flat cables will certainly increase. The pin line width and pin spacing vary according to the strength of the FPC manufacturer. At present, the minimum size of the manufacturer can be 0.1mm.

Due to the limitation of the overall thickness of the mobile phone, the rotating shaft, and the FPC vias of B/C pieces, the FPC cable width is generally designed to be 3 or 3.5mm (if it is calculated as 3.5mm, the distance between the two edges of the cable and the FPC edge is 0.4mm, based on the line width and the line spacing are both 0.1mm, so that each layer of board can be laid with about 13 cables), and the thickness is 0.2 or 0.3mm (FPC is a 2+2 or 3+2 structure).

When designing the shape of the FPC, we should pay attention to the clearance with B/C parts and vias. When the wall thickness and strength of B/C parts have been met, try to leave more space for the FPC. Because the FPC needs to pass through these places and swing with the flip opening and closing of the mobile phone, and the FPC itself is fragile, this place is also the place where the FPC is most likely to have problems. It is easy to scrape the FPC and the housing. Not only will there be a sound when the flip rotates, but also the FPC will break over time and affect its life.

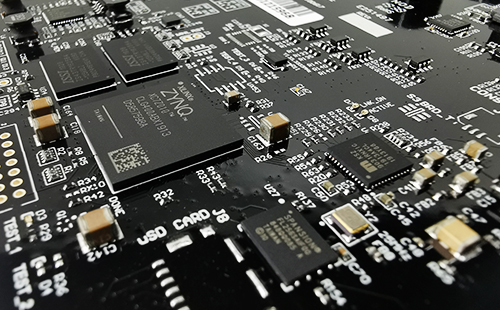

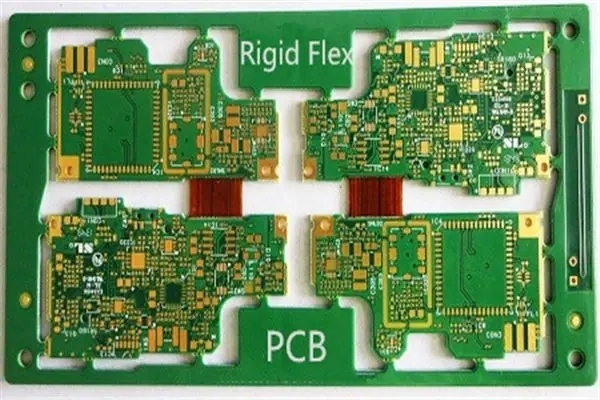

FPC circuit board

In addition, the large current connector is also indispensable in pipeline installation; Root nut, also known as root collar, lock nut, uses a short pipe section and a root nut with one end as a short screw thread, the other end as a long screw thread (with no tip at the root), plus a pipe hoop with the inner wall as a thread to form a filament, which functions as a movable joint and is used as a removable movable connection. When it is used on the radiator bushing, the threaded pipe hoop can also be omitted; The left and right flanges form a pair, which functions as a union. The specification is d50mm and above. Since the two ends of large valves are flange type interfaces, flange plates are also used for connecting pipes and valves.

The design of this place is the top priority of Guangjie's new design. Finally, I hope that when you use Pro/E to design FPC, you can use sheet metal module instead of part solid module, because in the sheet metal module, FPC can make the FPC shape that is closest to the actual situation. It is easy to bend and flatten, and it is easy to modify, so that you can truly simulate the theoretical real position of FPC in the vias.