Electronic products conSMT processingtinue to replace the status of traditional non electronic products and become indispensable everywhere. This also led to the assembly of electronic products in processing plants: must develop at an incredible speed to meet the growing demand of people today.

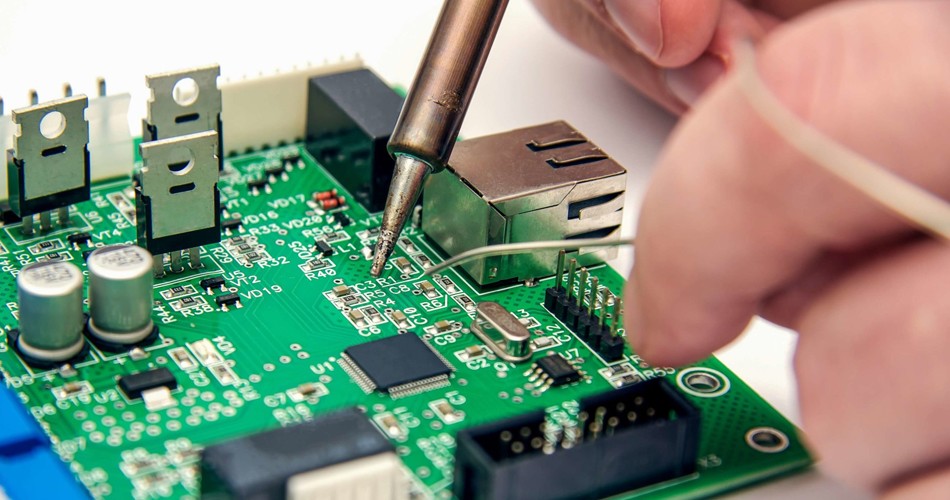

1、 SMT: The full English name is SurfaceMountTechnology, and the Chinese name refers to surface mount technology.

2、 SMT processing: also known as surface mount processing technology. Generally speaking, allSMT processing plants rely on this process.

3、 SMT processing fee: As the circuit board factory is processed and operated by SMT, it is necessary to set a price for its own PCB process in order to contact with the outside world.

SMT processing plants are more prone to this problem when users use new suppliers' products at an early stage or when the production technology is unstable. Through customer cooperation and many experiments, we finally analyze the reasons for the occurrence of tin beads in the following aspects:

1. PCB board is not preheated during reflow soldering;

2. The reflow temperature curve is set unfairly, and the plate surface temperature before entering the welding area is relatively small compared with the welding area temperature;

3. When the solder paste is taken out of the cold storage, it cannot completely recover to the room temperature;

4. The solder paste is exposed to the air for a long time after opening;

5. When placing the patch, the tin powder splashes on the PCB surface;

6. During printing or transfer, oil or water adheres to PCB;

7. In PCB solder paste, the flux itself is unevenly distributed, and it is difficult to evaporate solvent or liquid additives or activators.

There are many residues on the PCB surface after welding. This is also a problem that customers often report. More residues on the circuit board surface will not only affect the brightness of the circuit board surface, but also have an inevitable impact on the electrical characteristics of the PCB itself. The main reasons for excessive residues are as follows:

1. During the implementation of the solder paste, the customer did not know the sheet status and customer needs, or the failure was selected for other reasons; For example, the customer needs to use clean and residue free solder paste, while the solder paste manufacturer supplies rosin resin type solder paste so that customers can reflect more residues after welding. In this regard, the solder paste manufacturer may have been aware of the implementation of the commodity.

2. Too much rosin resin or poor quality in the solder paste; This may be a technical problem with the solder paste manufacturer.

SMT processing plant_ SMT processing_ Pcba patch

Now, Shenzhen, a city with developed electronic industry, has begun to diversify its SMT OEM model. Of course, in this process, we must choose the appropriate cost-effective manufacturers. In the casting process, technical advantages can be more obvious. By mastering these basic technical advantages, we can learn the most professional technology in casting.

With the continuous development of science and technology, SMT processing plant has adopted international advanced mechanical equipment and electronic equipment. The technical content of the casting industry is getting higher and higher, reaching the first-class technical level. For many electronic applications. The effect of this patch is obvious and the quality is guaranteed. It still has unique advantages in processing, and can create first-class technical advantages in the domestic market, reflecting the technical characteristics in this regard. This is a technical advantage available to many manufacturers in processing.

SMT processing is mainly used in electronic production process. This is a professional technical process, and the quality and performance achieved in the casting process are very good. At the present stage, there are more and more OEM factories in the domestic market. Which manufacturers and quality can be selected to achieve first-class advantages? Of course, Shenzhen SMT OEM is China's first-class production level and quality. In the process of processing, it is absolutely necessary to understand the process and characteristics of this technology, form a diversified processing technology advantage, and be recognized and trusted in the domestic market.