kingford will explain to you that the main purpose of SMT patch processing is to accurately install the surface assembly components to the fixed position of PCB. In the process of smt patch processing, some process problems may occur sometimes, which will affect the quality of the patch, such as the displacement of components, tin connection and welding leakage in SMT patch processing. Whatever the origin of the problem should be paid attention to.

SMT patch processing technology: Causes of component displacement in patch processing

In view of the reasons for no device displacement, the reasons can be found from the following aspects: The reasons for component displacement in patch processing:

1, the use of solder paste is limited, beyond the use period, resulting in the deterioration of the flux, poor welding.

2. The stickiness of the solder paste itself is not enough, and the components are displaced due to oscillation and shaking during handling.

3. The flux content in the welding paste is too high, and the excessive flux flow in the reflow welding process leads to the displacement of components.

4. The components are displaced due to vibration or incorrect handling in the process of printing and patching.

5. During patch processing, the air pressure of the nozzle is not adjusted well, and the pressure is not enough, resulting in the displacement of components.

6. The mechanical problem of the SMT machine itself caused the wrong placement of the components.

Once component displacement occurs in smt patch processing, the performance of the circuit board will be affected. Therefore, it is necessary to understand the causes of component displacement in the processing process, and to solve the problem.

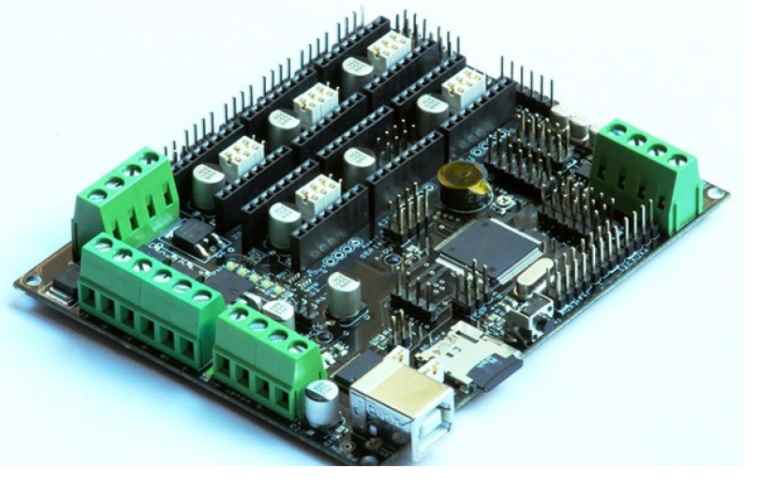

2. Composition and classification of SMT production line

The smt line consists of a number of production equipment, each of which does a different job, but each of which ultimately aims at a printed circuit board. smt production equipment has the characteristics of full automatic, high precision, high speed and high efficiency. What equipment does a complete and efficient smt production line consist of?

Usually, the main production equipment of smt production line includes solder paste printing machine, dispensing machine, patch machine, reflow welding and wave welding machine. Auxiliary equipment includes AOI testing equipment, X-RAY equipment, SPI equipment, repair equipment, cleaning equipment, drying equipment and material storage equipment, etc.

smt patch processing plant

In addition, according to the degree of automation, production scale and production attributes, we can also divide production lines into the following types:

According to the degree of automation classification: can be divided into automatic production lines and semi-automatic production lines. Automatic production line refers to the whole production line equipment is automatic equipment, through automatic loading machine, buffer belt and automatic unloading machine will all production equipment into an automatic line. Semi-automatic production lines are those in which the main production equipment is not connected or not fully connected. Printing presses are semi-automatic and require manual printing or loading and unloading of printed circuit boards.

According to the size of the production line classification: printed circuit board production lines can be divided into large, medium and small production lines. Large production line has a larger production capacity, a large single-side production line of the SMT machine by a universal machine and a number of high-speed units. Medium and small production lines are mainly suitable for research institutes and small and medium-sized enterprises to meet the needs of multiple varieties, small and medium-sized batches or single varieties. Medium and small batch production tasks can use automatic production lines or semi-automatic production lines.

According to the different classification of production products: the production line of printed circuit board can be divided into single production line and double production line. A single line of printed circuit boards consists of automatic surface assembly equipment such as printing press, SMT machine, reflux furnace, test equipment, etc., which is mainly used to assemble SMC/SMD products on only one side of the PCB.

The PCB double production line consists of two PCB single production lines, which can exist independently or in series. It is mainly used to assemble SMC/SMD products on the PCB double side.

When we need smt patch processing or need to look for smt patch processing manufacturers, we need to select suitable smt patch processing plants according to our actual needs and the positioning of different manufacturers