1. Definition and addition of cascade

For high-speed multilayer board, the default two-layer design cannot meet the requirements of wiring signal quality and wire density, so it is necessary to add PCB layering to meet the design requirements.

2. Positive layer and negative layer

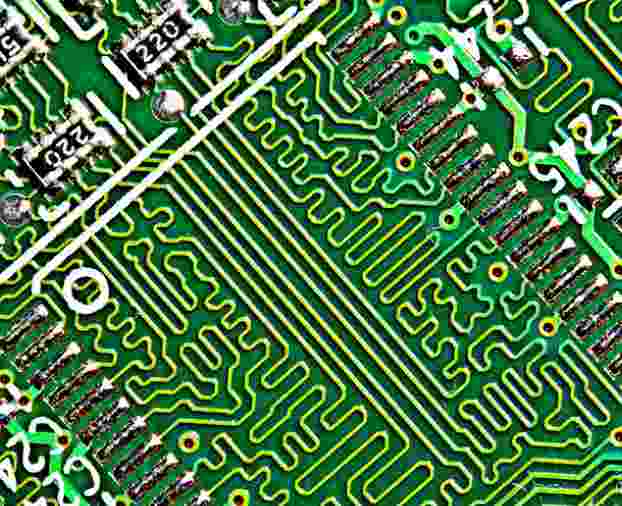

Positive layer is usually used to route the signal layer (intuitively see the place is copper wire), can use "line" "copper skin" and other large copper paving and filling operation, negative layer is the opposite, that is, the default copper paving, is generated after a negative layer of the whole layer has been paved with copper, the place of the line is the dividing line, there is no copper. What we need to do is to divide the copper, and then set up the network of the divided copper,

3. Segmentation of the internal electrical layer

In the Protel version, the internal voltage is divided by "splitting", whereas the current version, Altium Designer 19, is directly divided by "line", shortcut "PL". Dividing line should not be too thin, can choose 15mil and above. To divide the copper, just draw a closed polygon box with the "line", and then double-click the copper in the box to set the network.

Both positive and negative film can be used for internal electrical layer, and positive film can also be achieved by wiring and copper laying. The advantage of negative film is that the default bulk copper filling, then add holes, change the size of the copper do not need to re copper, which saves the time of re copper calculation. When power layer and GND layer (also known as ground layer, ground layer and ground layer) are used in the middle layer, most of the layers are paved with copper in large pieces, so the advantage of negative film is obvious.

4. Knowledge of PCB layering

With the emergence of high-speed circuits, the complexity of PCB is also increasing. In order to avoid the interference of electrical factors, the signal layer and the power layer must be separated, so the design of multi-layer PCB is involved. Before designing a multilayer PCB, the designer needs to first determine the board structure according to the size of the circuit, the size of the board and electromagnetic compatibility (EMC) requirements, that is, decide to use four, six, or more layers of the board. This is a simple concept for designing multilayer panels.

After determining the number of layers, determine where to place the internal layers and how to distribute the different signals on them. This is the selection of the layered PCB structure. The laminated structure is an important factor affecting the EMC performance of PCB. A good laminated design scheme will greatly reduce the influence of electromagnetic interference (EMI) and crosstalk.

The number of layers of the board is not the more the better, nor the less the better, to determine the laminated structure of multi-layer PCB needs to consider more factors. From the wiring aspect, the more layers, the more conducive to wiring, but the cost and difficulty of the board will increase. For manufacturers, the symmetry of laminated structure is the focus of PCB manufacturing. Therefore, the selection of layers needs to consider all aspects of the needs, in order to achieve the best balance.

For experienced designers, after completing the pre-layout of components, the PCB routing bottleneck will be analyzed, and then the number and type of signal lines with special wiring requirements (such as differential lines, sensitive signal lines, etc.) to determine the number of signal layers, and then according to the type of power supply, isolation and anti-interference requirements to determine the number of layers of the internal electrical layer. In this way, the number of layers of the entire circuit board is basically determined.

5. Common PCB layering

After determining the number of layers of the circuit board, the next job is to arrange the placement of each layer of circuits in a reasonable order. Common 4 - and 6-ply laminated structures are listed.

6. Cascade analysis

How do you stack them? Which is better? The following basic principles are generally followed.

① Component surface and welding surface are complete ground plane (shield).

② No adjacent parallel wiring layer as far as possible.

③ All signal layers are adjacent to the ground plane as far as possible.

(4) The key signals are adjacent to the strata and do not cross the segmentation area.

According to the above principles, the common cascading schemes can be analyzed as follows.

(1) Comparison of advantages and disadvantages of three common 4-layer laminated schemes

Through the comparison of scheme 1 to scheme 4, it is found that scheme 3 and scheme 4 are obviously better than the previous two schemes when the signal is given priority. But in the actual design, the product is more care about the cost, and then because of the high wiring density, usually choose scheme 1 to do the overlapping structure, so in the wiring must pay attention to the signal cross-wiring of two adjacent signal layers, as far as possible to minimize the crosstalk.

(3) The common stacking scheme of 8-layer plates is recommended, scheme 1 and scheme 2 are preferred, and scheme 3 is available.

7. Add and edit layers

After confirming the cascading scheme, how to add layers in Altium Designer? The following is a simple example.

(1) Run the menu command "Design-Cascade Manager" or press the shortcut key "DK" to enter the Cascade Manager and set related parameters.

(2) Right-click the mouse button and run the Insert layer above or Insert layer below command to add layers. You can add positive or negative slices. Run the Move layer up or Move layer down command to adjust the sequence of layers to be added.

(3) Double-click the corresponding name, you can change the name, generally can be changed to TOP, GND02, SIN03, SIN04, PWR05, BOTTOM, that is, "letter + layer number (Altium Designer 19 comes with this function)", so as to facilitate reading and identification.

(4) Set plate thickness according to the laminated structure.

(5) In order to meet the design 20H, the inner shrinkage of the negative layer can be set.

(6) Click OK to finish the cascading Settings. A 4 layer laminated effect

It is suggested that the signal layer should adopt the positive processing mode, and the power layer and ground layer should adopt the negative processing mode, which can greatly reduce the size of the file data and improve the design speed.