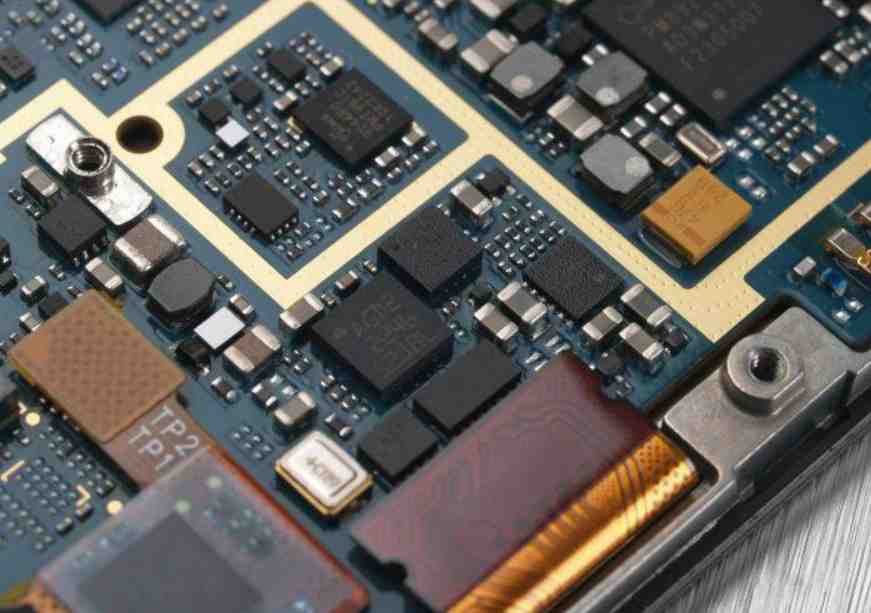

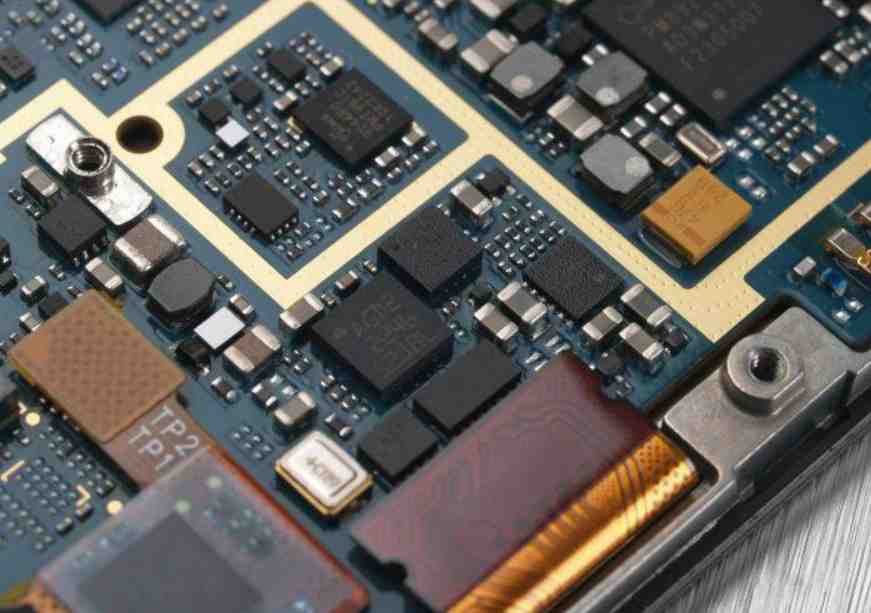

The importance of PCB design in electronic products is self-evident, and therefore, once there is a problem in the product, it is necessary to consider whether it is because of poor PCB design. For example, the crystal vibration does not vibrate during product debugging, which may be because of the crystal vibration device itself, or it may be because of PCB design reasons.

The reason of crystal vibration

The crystal oscillator itself has problems

This possibility is relatively large, mainly reflected in the following places:

1. Wrong selection of material parameters

For example, a product needs to match the 32.768KHz 6PF crystal oscillator, but the result is that 12.5PF crystal oscillator is selected, resulting in the crystal oscillator not vibrating.

Solution: Replace the crystal oscillator that meets the requirements.

2. Frequency deviation exceeds normal value

If the actual oscillation frequency is outside the required frequency range of the module, data transmission/reception errors will occur, resulting in non-vibration of the crystal.

Solution: Choose a product with the right PPM. When the circuit center frequency is positively biased, it indicates that CL is small, and the value of external capacitor Cd and Cg of crystal oscillator can be increased. When the circuit center frequency is negatively biased, it indicates that CL is too large, which can reduce the value of external capacitor Cd and Cg of crystal oscillator.

3. The crystal sheet inside the crystal oscillator is broken or damaged

Damage in the process of transportation, or falling, impact and other factors in the process of use will cause damage to the crystal crystal inside the crystal oscillator, resulting in the crystal oscillator cannot vibrate.

Solution: Replace the good crystal oscillator.

Note: In order to avoid the crystal vibration in the transport process of strong collision, to use a thicker foam package; The crystal oscillator that has fallen from the high air, or has experienced heavy weight or impact, shall not be used again.

4. Impurities or dust are attached to the crystal pieces inside the crystal oscillator

In the process of crystal oscillator production, there is the process of crystal plate electrode plating, that is, the crystal plate is plated with a layer of gold or silver electrode. If dust particles in the air are attached to the electrode, or there are gold slag and silver slag remaining on the electrode, the crystal oscillator will not vibrate.

Solution: Replace new crystal oscillator.

Note: Crystal plate electrode plating is required to be completed in 10,000 level dust-free workshop. Manufacturer's equipment, workshop environment and process are directly related to product quality.

5. There is gas leakage in crystal vibration

In the process of crystal vibration, the internal vacuum is required to be filled with nitrogen. If the pressure seal is poor, the air tightness of crystal vibration is not good and gas leakage occurs. Or poor air tightness of crystal vibration in the welding process due to mechanical stress of the product in the process of cutting feet; All of these results will cause the phenomenon of non-vibration of crystal vibration.

Solution: Replace the good crystal oscillator. In the process and welding process must be standardized operation, avoid misoperation resulting in product damage.

PCB design reasons

Although this reason is less likely, but also exists. Crystal vibration in printed circuit board needs to check and pay attention to the following contents:

1. The crystal circuit should be placed as close as possible to the clock pin of the chip, and the wiring should be as short as possible to reduce the load capacitance of the line and prevent unnecessary noise;

2. If the crystal oscillator is too close to the edge of the board, it is easy to cause noise from the crystal oscillator radiation. It is recommended to be more than 10mm away from the PCB circuit board edge.

3, clock routing Xin and Xout and the second layer below the crystal need to be a complete ground plane to do isolation, projection area is recommended to prohibit any routing, to avoid noise coupling into the clock circuit;

4. The crystal circuit is placed around the ground ring. The ground ring is connected to the adjacent ground layer through the hole to isolate the noise. If the chip has a crystal vibration simulation ground, it needs to separately hole to the plane.

5. The two load capacitors of the crystal oscillator are close to the crystal oscillator, and the signals pass first and then to the main chip. The filtering capacitor of active crystal oscillator should be as close as possible to the power supply pin of crystal oscillator. The position placement sequence is as follows: in the direction of power supply inflow, the capacitor with the smallest capacity is closest to the power supply pin.

Confirm the above problems can basically determine whether the crystal vibration circuit design on PCB board is reasonable.

Knowledge expansion: Crystal oscillator

Crystal oscillator is the most commonly used and indispensable component in electronic products. As small as mobile phones and computers, as large as missiles and satellites, crystal oscillator is needed. It is known as the "heart of electronic equipment" and plays a key role in electronic systems.

The effect of crystal oscillator

Crystal oscillator is the most important part of the clock circuit, its main role is to provide the video card, network card, motherboard and other parts of the reference frequency, it is like a ruler, working frequency instability will cause the related equipment working frequency instability, naturally prone to problems. Under normal operating conditions, the absolute accuracy of ordinary crystal frequency can reach 50 parts per million, and the accuracy of advanced crystal frequency is higher.

Another function of crystal oscillator is to provide the basic clock signal to the system. Usually a system shares a crystal oscillator, so that all parts can keep up with each other. Some communication systems use different crystal oscillators for the fundamental and RF frequencies, which are kept in sync by electronically adjusting the frequencies